Device and method for disposing sludge based on chemical looping combustion

A chemical chain combustion and sludge technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of high organic nitrogen content and large nitrogen oxide emissions, and achieve inhibition of NOx generation and elimination of dioxins. The effect of production, extensive social benefits and industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

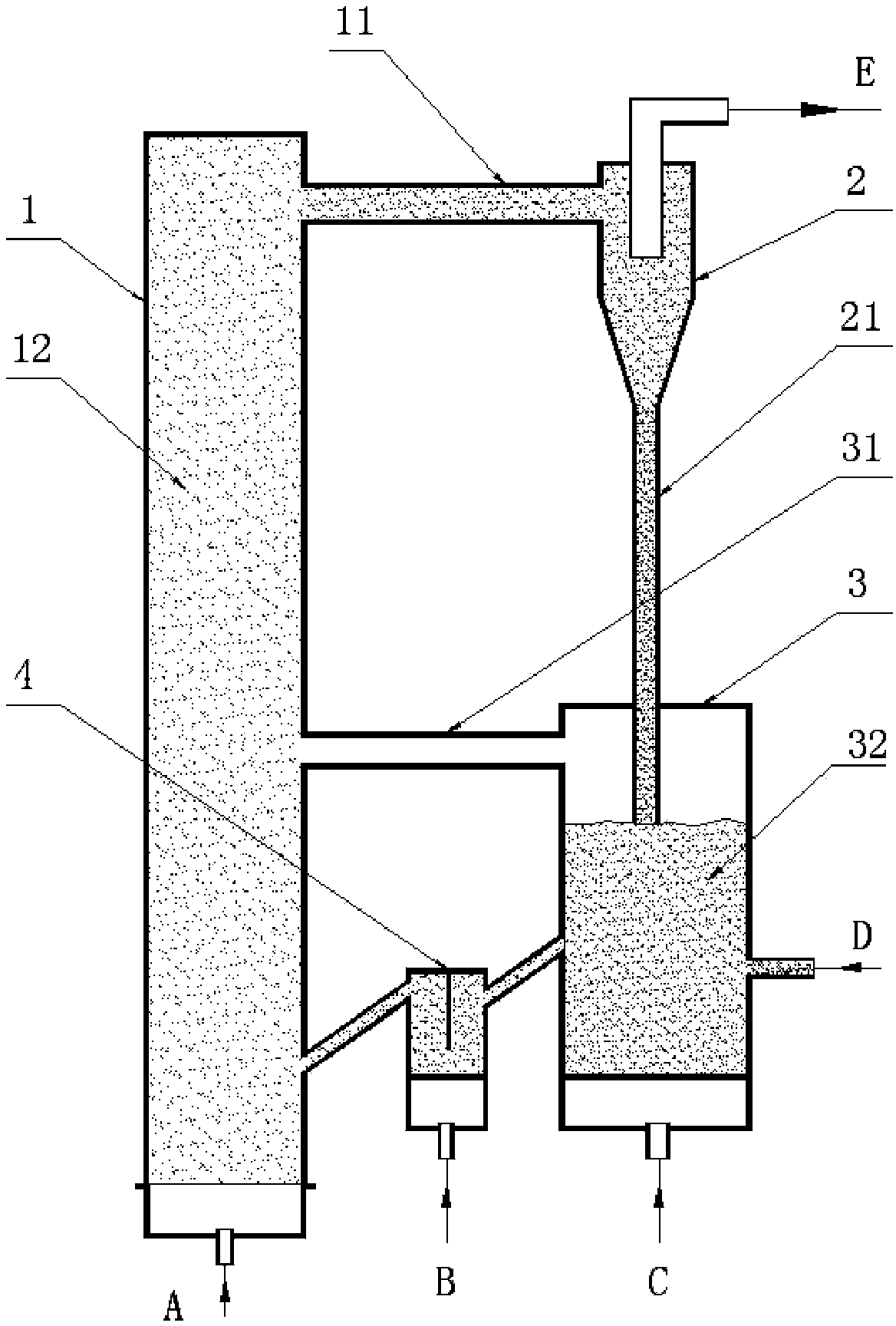

[0019] The device and method for treating sludge based on chemical looping combustion of the present invention are composed of an air reactor 1, a cyclone separator 2, a fuel reactor 3 and a feeder 4 connected to form a circulation loop. The air reactor exhaust pipe 11 on the upper part of the air reactor 1 communicates with the upper part of the cyclone separator 2, the lower part of the cyclone separator 2 communicates with the fuel reactor 3 through the dipleg 21, and the middle part of the fuel reactor 3 passes through the return material The device 4 communicates with the bottom of the air reactor 1, and the top of the fuel reactor 3 communicates with the middle or upper part of the air reactor 1 through a fuel reactor exhaust pipe 31; the bottom of the air reactor 1 is provided with an air inlet A, The top of the cyclone separator 2 is a flue gas outlet E, the top or top of the fuel reactor 3 is provided with a fuel reactor exhaust pipe 31, the bottom of the fuel reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com