Method for determining altitude difference between roller braking bed and ground

A determination method and technology of braking platform, applied in vehicle testing, machine/structural component testing, measuring device, etc., can solve the problems of reduced braking force, irregular detection, difficulty in meeting front axle detection requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method for determining the height difference between the drum braking table and the ground, its specific implementation is exemplified as follows:

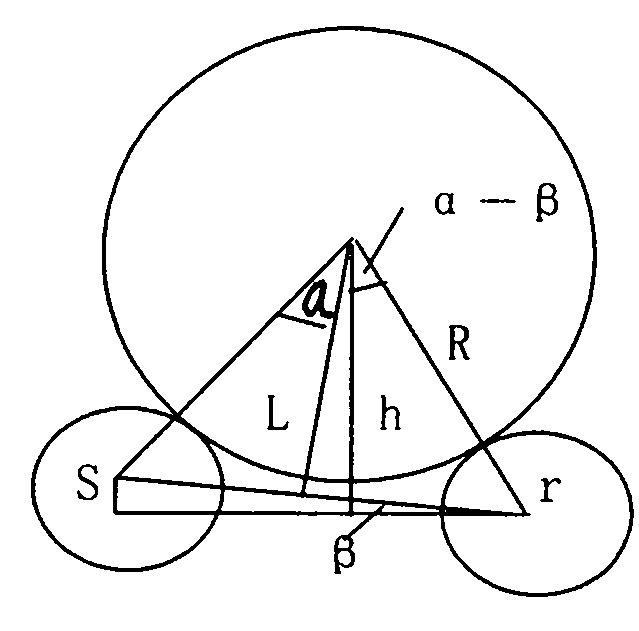

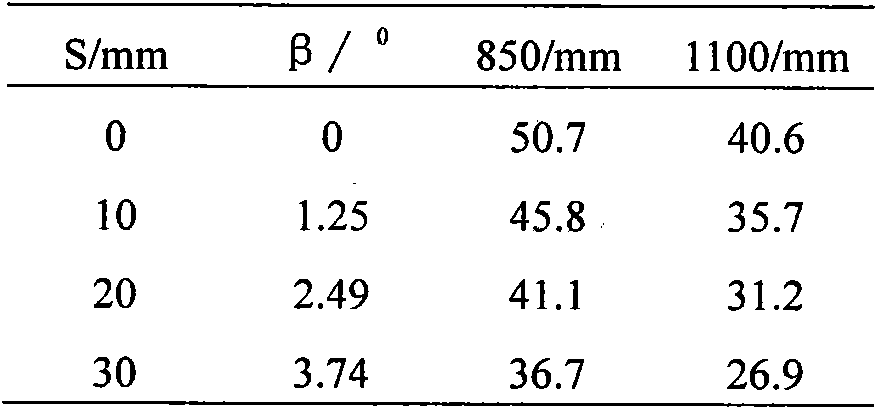

[0018] Multi-axle vehicles are generally heavy-duty vehicles, usually with wheel diameters ranging from 850mm to 1100mm. According to Table 1 of GB / T13564-2005 "Roller Reaction Vehicle Brake Test Bench", the rollers of the heavy-duty vehicle stand with a rated load capacity of 10t The recommended center distance is 450mm, and the recommended center distance of the rollers of the heavy-duty vehicle platform with a rated load capacity of 13t is 470mm. If the average value is L=460mm, and R is the wheel radius, take 850 / 2=425mm and 1100 / 2=550 respectively. r is the radius of the roller, according to the national standard r is taken as 245 / 2=122.5mm, S is the axis height difference between the main roller and the auxiliary roller, sinα=0.5×L / (R+r), sinβ=S / L, The installation angle of the wheel on the auxiliary drum is (α-β)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com