Super capacitor

A supercapacitor and electrode column technology, applied in the field of capacitors, can solve problems such as electrolyte leakage, seal damage, capacitor scrapping, etc., and achieve the effects of extending service life, tight contact, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

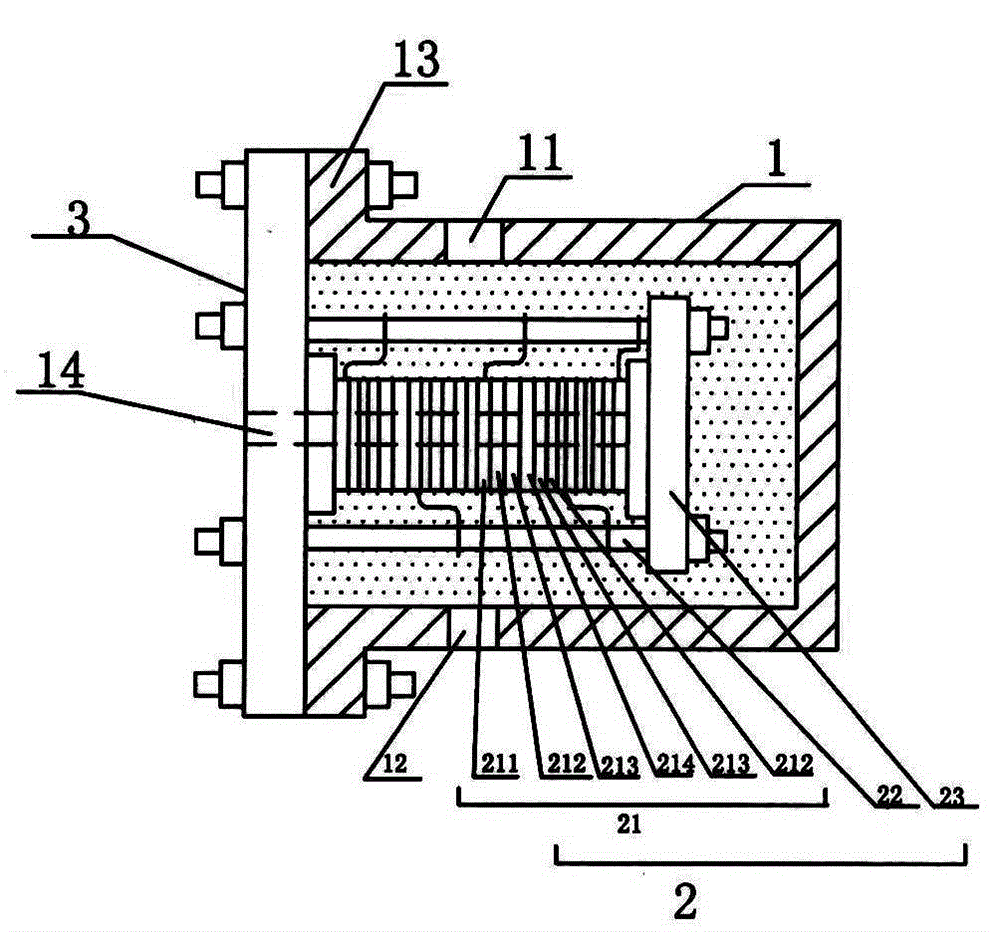

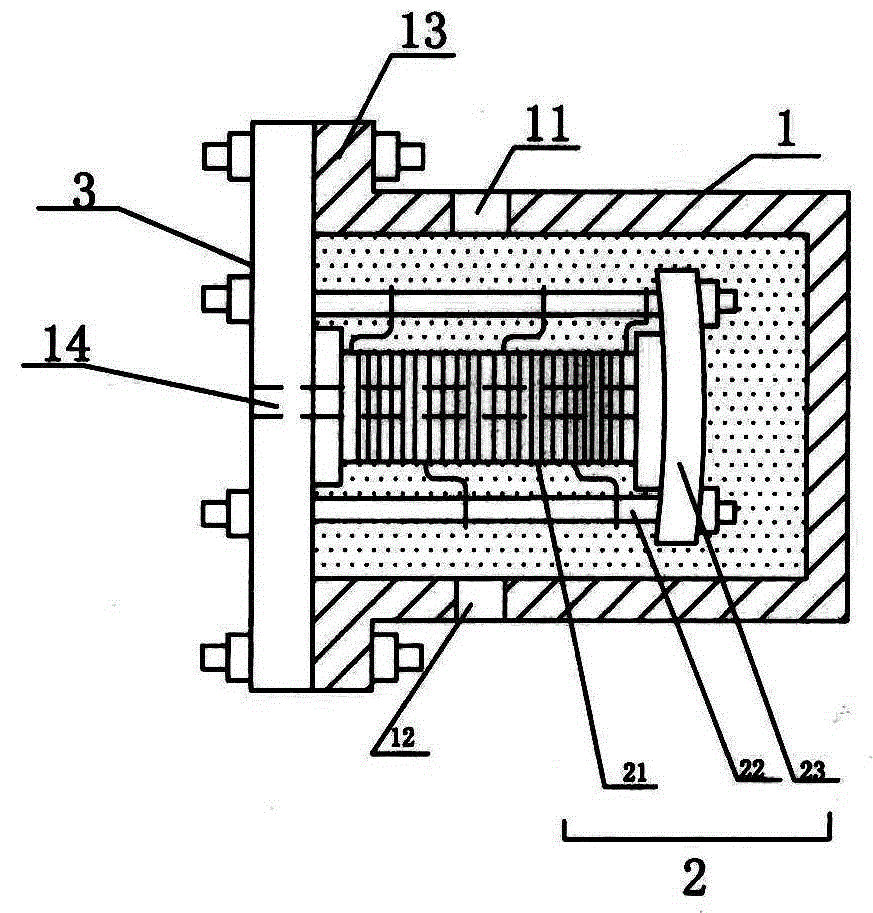

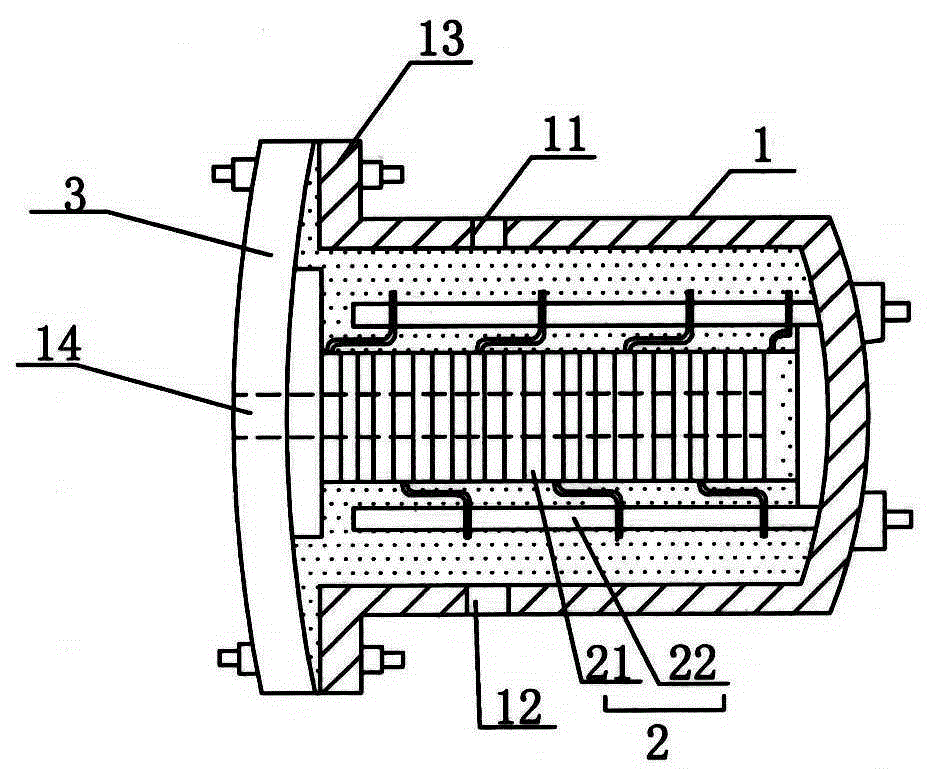

[0039] Embodiment 1, making a 20-layer electrode group and a rectangular supercapacitor

[0040] 1. Materials

[0041] 1. Electrode group material

[0042] Current collector: graphite paper, 0.5 mm thick, 18X25 cm, with a hole of ?10 in the center, 21 sheets;

[0043] Carbon electrodes: 18X18 cm, 0.5 mm thick, with a hole of ?10 in the center, 40 sheets;

[0044] Polyester mesh diaphragm: 0.15 mm thick, 20X20 cm, with a ?5 hole in the center, 20 sheets;

[0045] Cation separation membrane: 19X19 cm, 0.02 mm thick, with ?7 holes in the center, 20 sheets;

[0046] Anion separation membrane: 19X19 cm, 0.02 mm thick, with ?7 holes in the center, 20 sheets.

[0047] 2. Electrode column

[0048] ?10 through-wire titanium columns, 12 cm long, 6 pieces; ?10 hexagonal titanium nuts, 1 cm thick, 24 pieces.

[0049] 3. End cap

[0050] End cap: 30 cm long, 23 cm wide, and 3 cm thick, with honeycomb-shaped ribs (3 cm high). Correspondingly drill 2 rows of linear holes, each with 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com