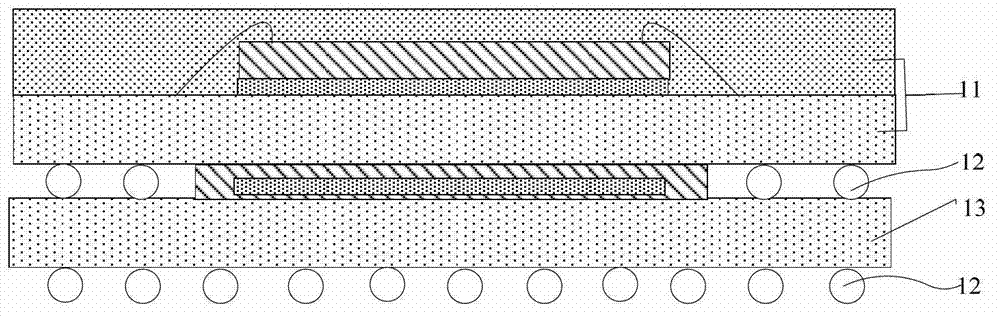

Fine spacing laminated packaging structure containing copper pillar and packaging method

A stacked packaging and fine-pitch technology, which is applied to semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of high cost and high cost of electroplating, achieve high production efficiency, omit complex processes, and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

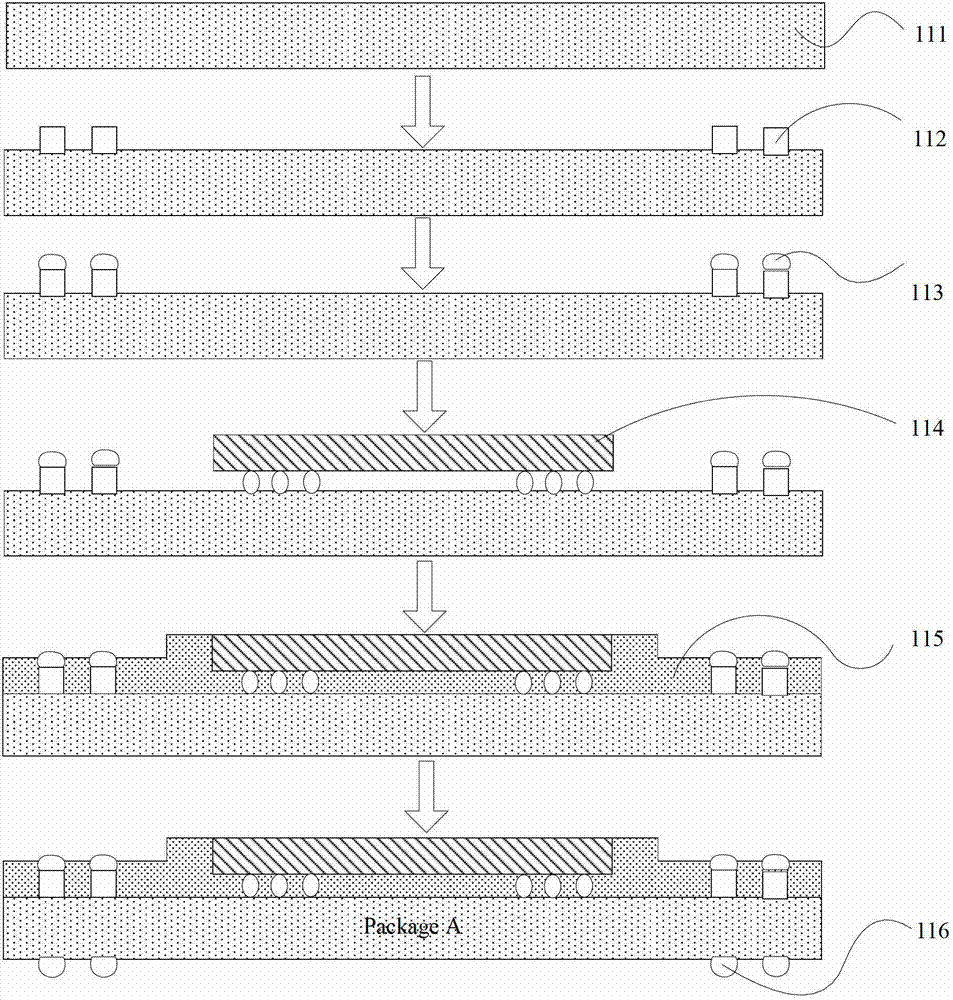

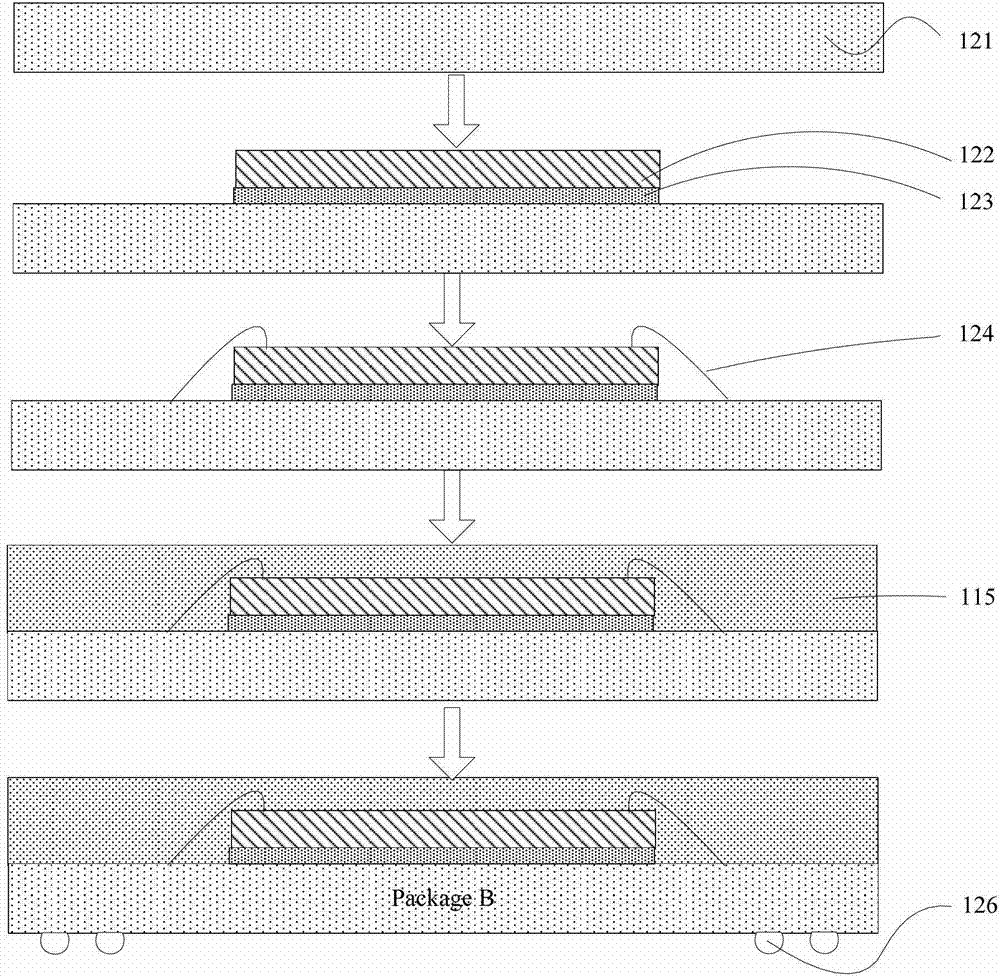

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0039] As mentioned in the background art, in the existing POP packaging technology, since the solder balls (ie, solder bumps) need to be higher than the height of the chip in the common process, it is impossible to achieve fine-pitch packaging interconnection. In the process of Shennan Company, although the copper pillars are made by electroplating and the balls are planted, relatively thin conductive vias can be produced, but the electroplating process itself is an expensive and cumbersome process, which affects the efficiency and efficiency of packaging. cost.

[0040] Therefore, the present invention proposes a new POP packaging structure and packaging method, which can achieve fine pitch between solder bumps by reducing the size of solder bumps themselves, which can help reduce the pitch size of solder bumps. In the prior art, soldering bumps are limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com