Gas-phase photocatalysis reaction device

A gas-phase photocatalysis and reaction device technology, which is used in chemical analysis using catalysis, chemical/physical/physical-chemical processes using energy, etc., to achieve the effects of controllable reaction conditions, good system airtightness, and high test stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

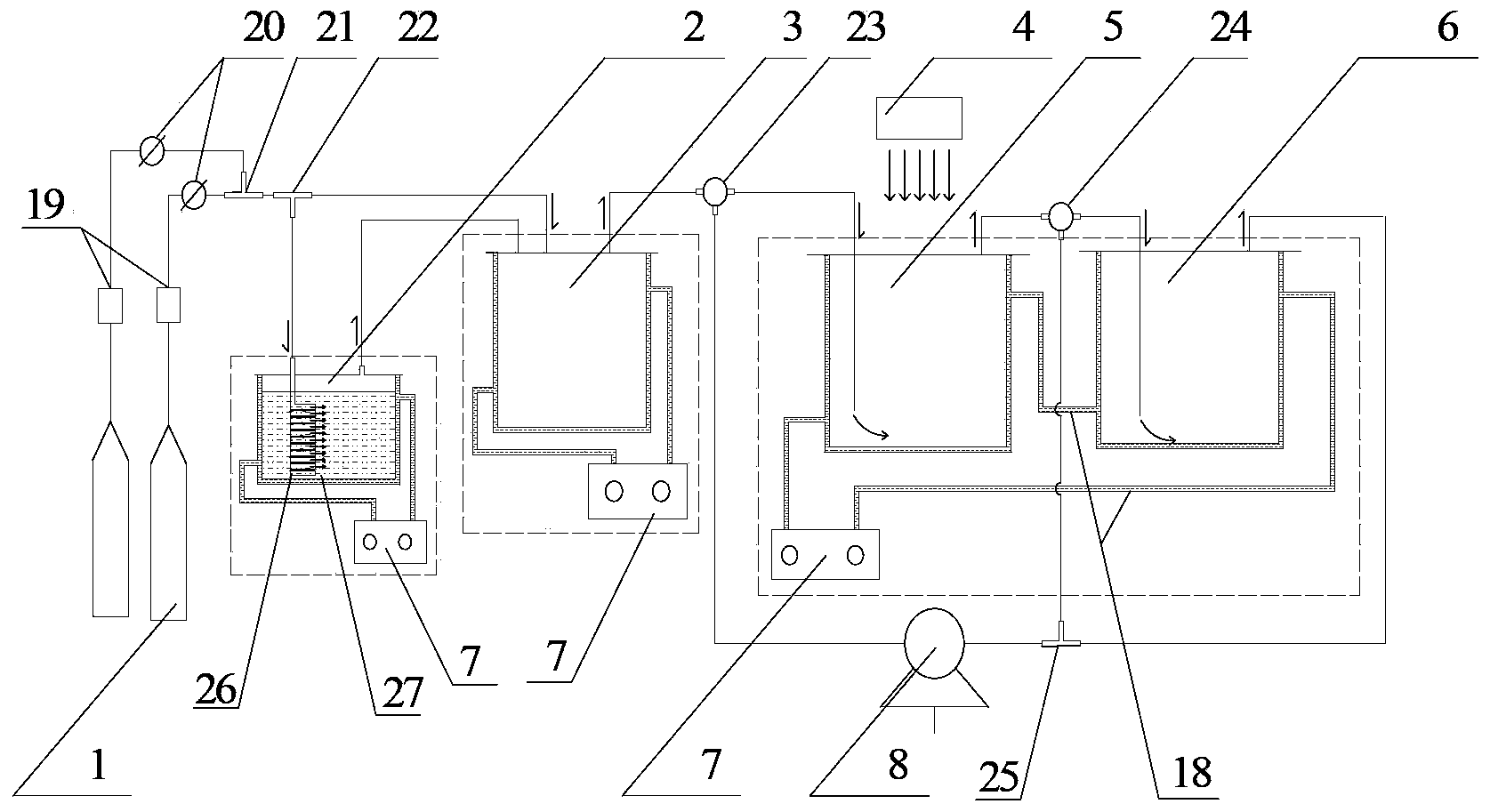

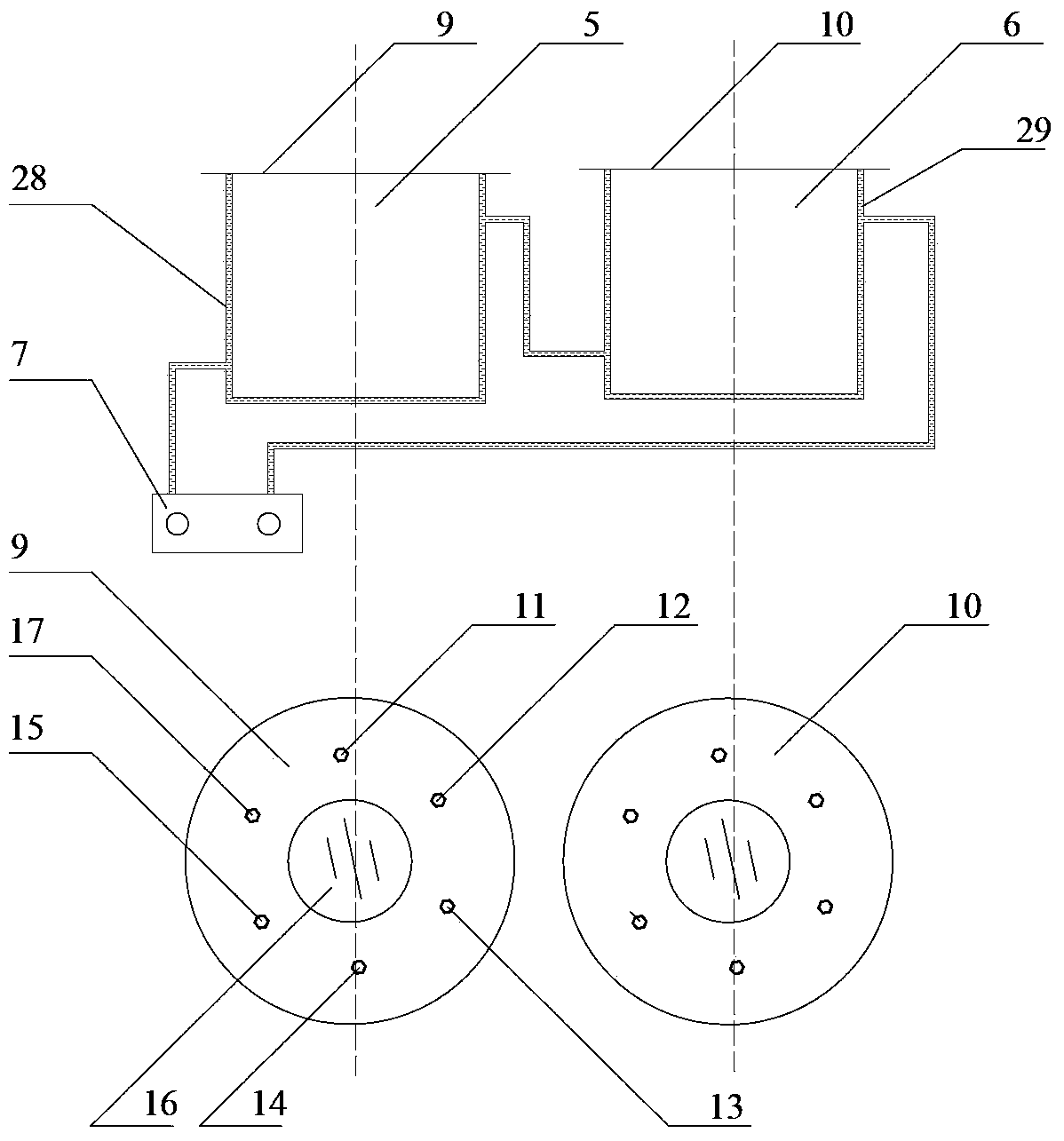

[0020] The two steel cylinders 1 are respectively connected to two interfaces of the first three-way interface 21 through the air pressure adjustment control device 19 and the gas flow meter 20, and the other interface of the first three-way interface 21 is connected to the second three-way interface. One port of the communication port 22 is connected, and the other two ports of the second three-way port 23 are respectively connected with the air inlet of the coil structure 26 with air holes on the side of the gas humidifier 2 and the gas mixing chamber through pipelines. 3, the gas outlet of the gas humidification device 2 communicates with the other gas inlet of the gas mixing chamber 3 through a pipeline, and the gas outlet of the gas mixing chamber 3 is connected to the first tee One port of the regulating valve 23 is connected, and the other two ports of the first three-way regulating valve 23 are respectively connected with the air inlet of the gas phase reaction chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com