Adhesive connection method of original bamboo and bicycle metal joint

A technology of metal joints and connection methods, which is applied to the front fork, can solve the problems of high skill requirements, high processing costs, and reduced hardness, and achieve the effects of low operation skill requirements, safe processing process, and low processing price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained in conjunction with specific drawings.

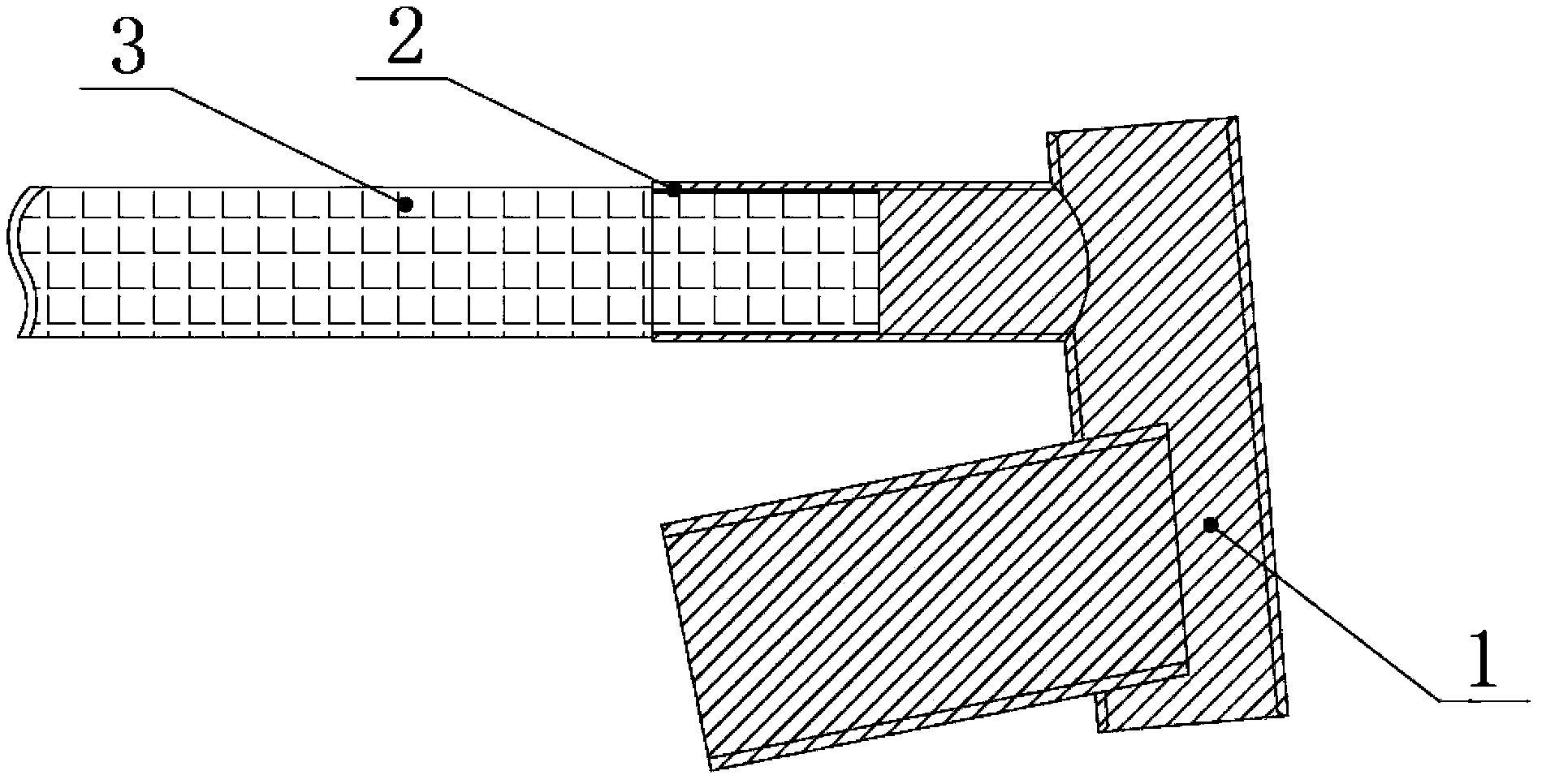

[0037] Reference figure 1 with figure 2 As shown, including metal joint 1, raw bamboo 3, snap the raw bamboo 3 into the mounting hole of the metal joint 1, and add epoxy resin 2 at the joint,

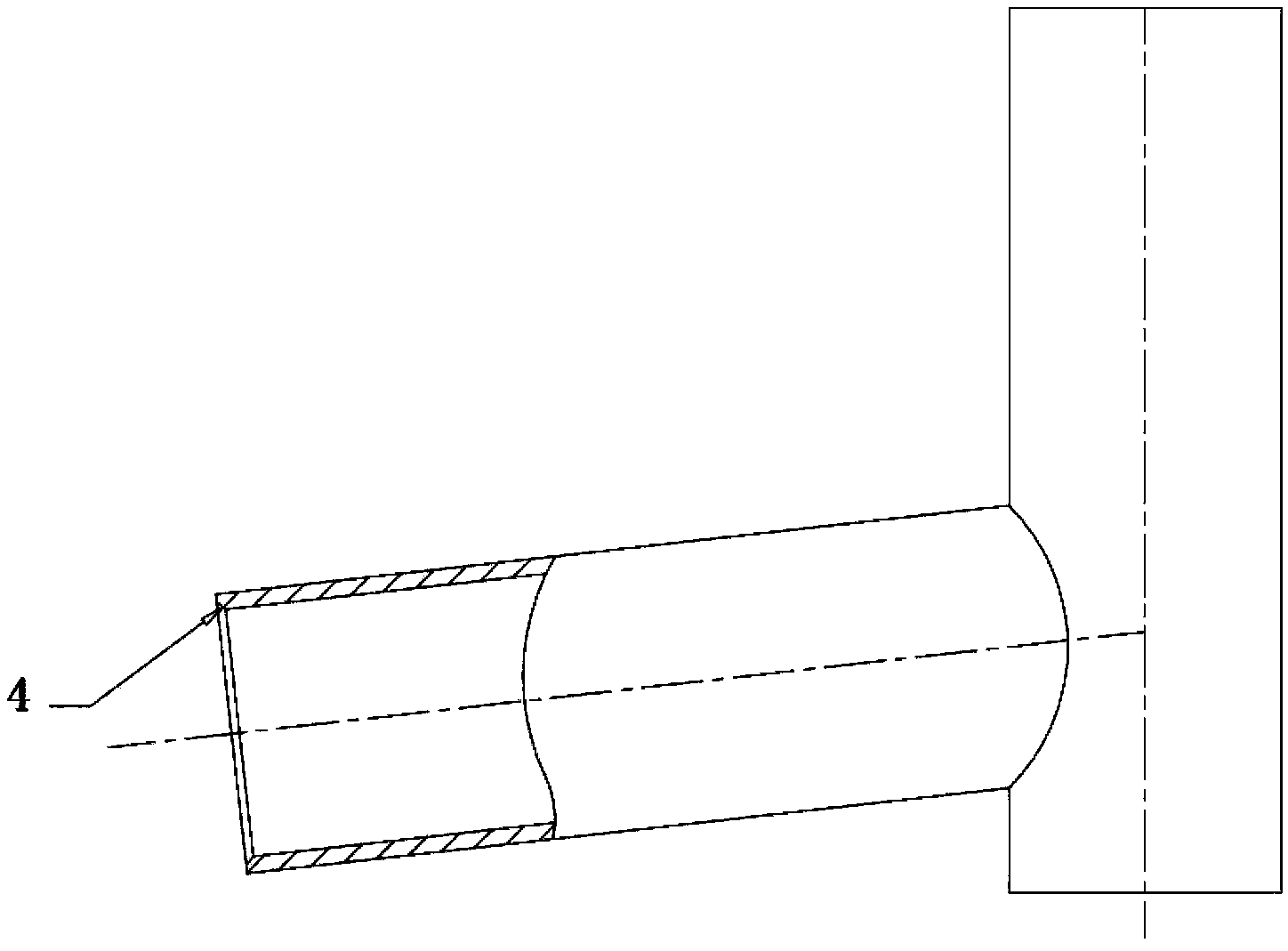

[0038] The metal joint is processed into a bevel to reduce the cutting force during the vibration process. The inner wall of the metal joint is provided with a 45-degree chamfer 4, which facilitates the assembly of raw bamboo into the installation hole of the metal joint.

[0039] Carbon fiber short filaments are added to the epoxy resin to enhance the adhesion and reduce the fluidity of the epoxy resin.

[0040] The gluing connection method of raw bamboo and bicycle metal joint includes the following steps:

[0041] 1) First, the raw bamboo is processed by the pre-treatment pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com