Method for preparing porous ceramic microspheres with different pore structures and spraying and freezing device

A technology of porous ceramics and pore structure, applied in the field of ceramic materials, can solve the problems of uneven distribution of porous particle size and poor controllability of porous structure, and achieve the effect of enhancing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

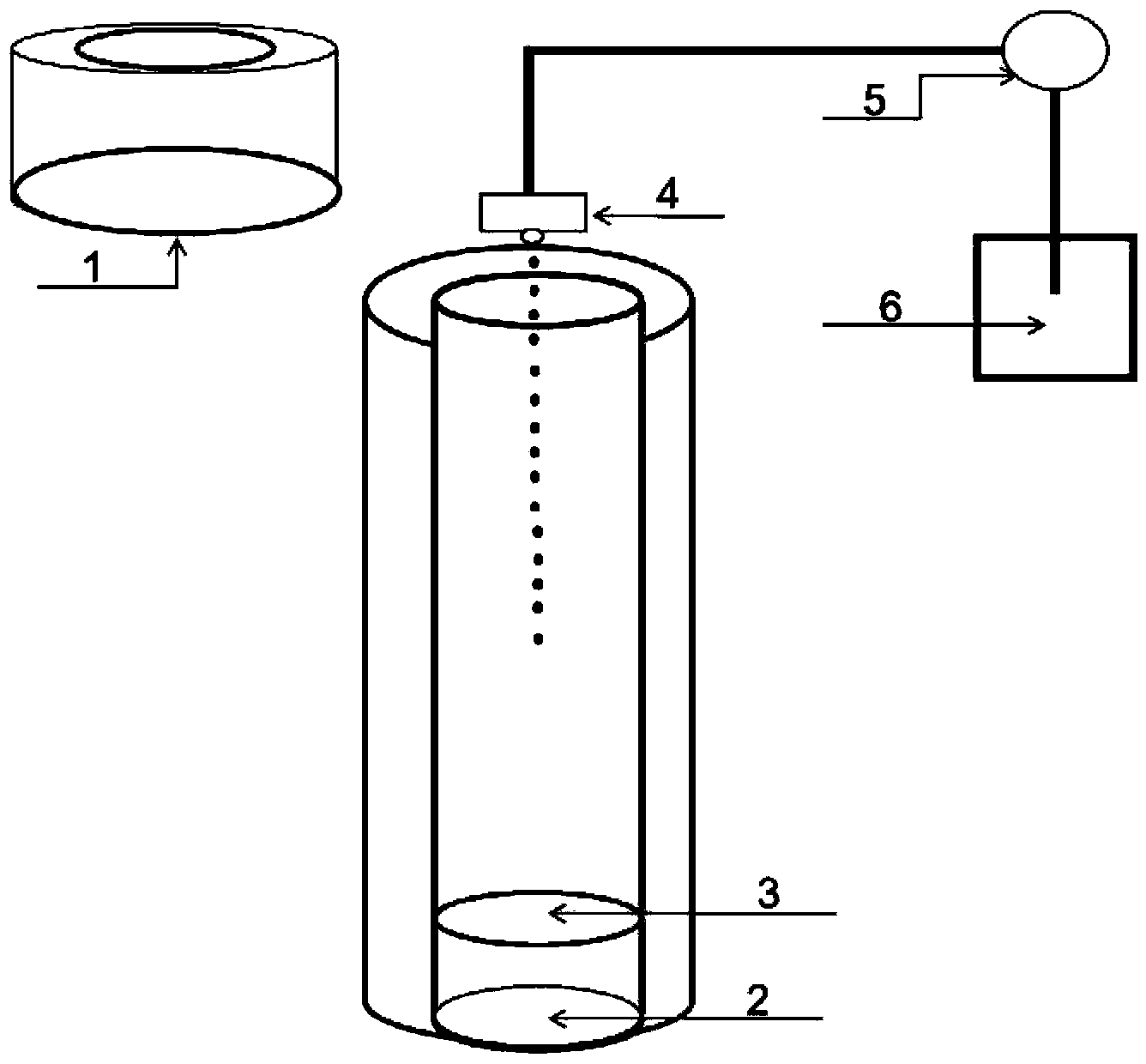

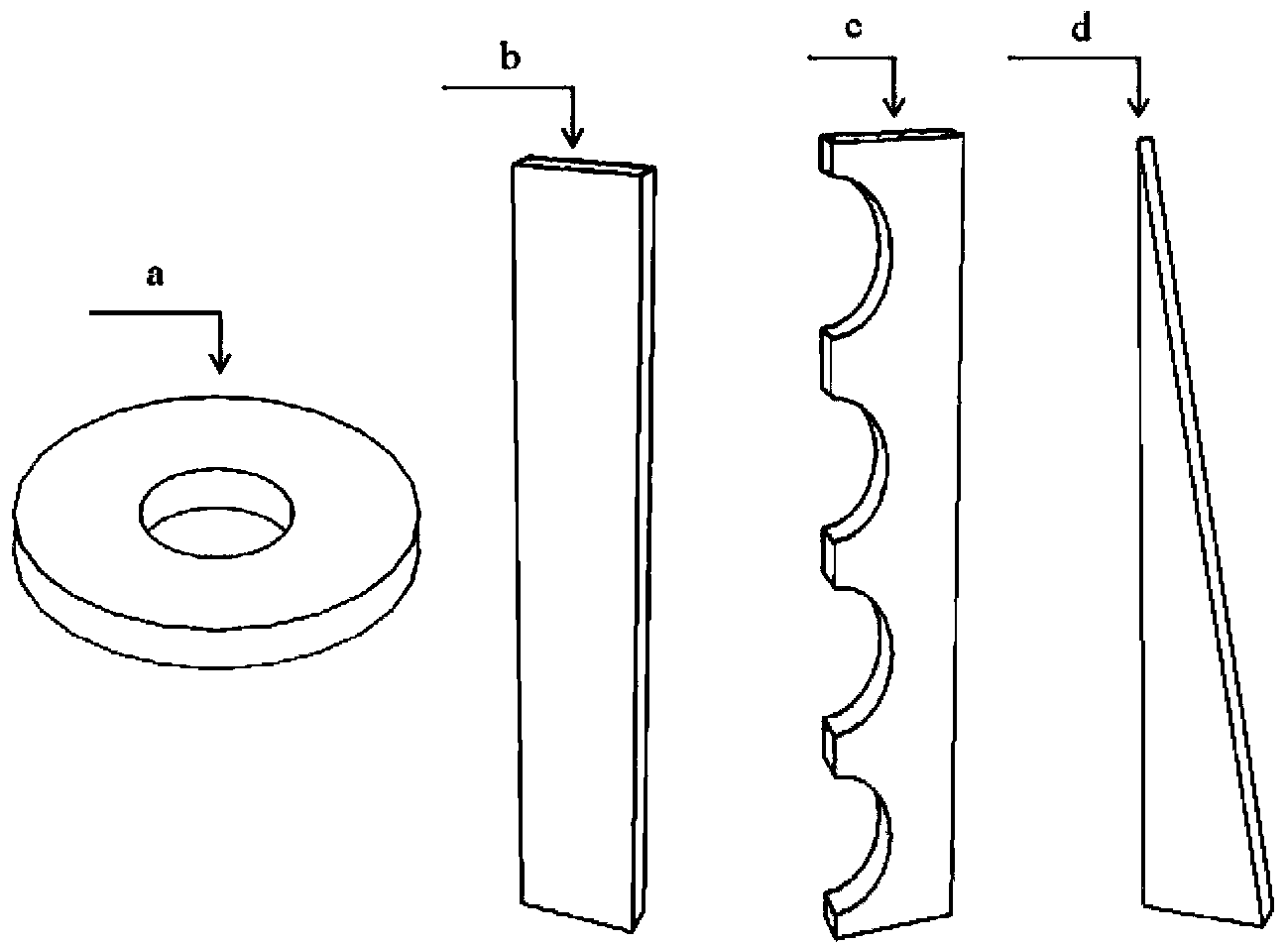

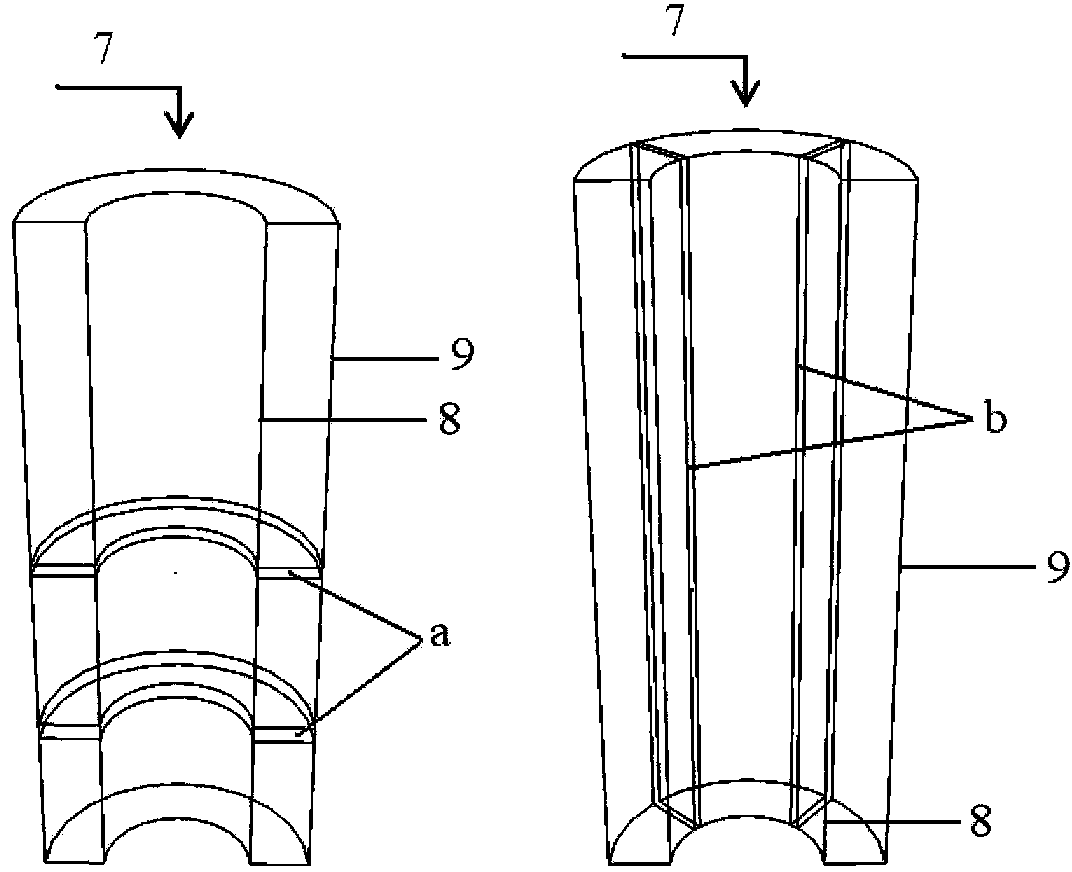

[0046] The method of freezing the slurry in the spray freezing device: install a baffle (a, b, c or d) between the two concentric cylinders (8, 9) of the cylindrical liquid nitrogen container (7) of the freezing device, and then A certain amount of liquid nitrogen is filled between two concentric cylinders (8, 9), so that the liquid nitrogen is distributed along the circumference of the cylinder and separated by baffles (a, b, c or d) into several parts , after covering the cover (1) on the top of the concentric cylinder (8, 9), replace the screen (3) according to the required size of the ceramic particles, then adjust the height of the sprayer to spray the slurry, and the slurry droplets pass through the cover (1) The circular hole in the middle enters the annular temperature field provided by the cylindrical liquid nitrogen container in the freezing device for freezing, and the obtained particles fall to the bottom of the small radius cylinder (8), and after being selected by...

Embodiment 2

[0048] 1) Mix alumina powder (particle size about 0.3μm) and deionized water at a mass ratio of 1:15, ball mill for 24 hours, and then add 1wt.% PVA aqueous solution (1wt.% of the total mass of the slurry) , and then ball milled for 1h, and prepared into a slurry with a solid phase content of 6.2wt.%.

[0049] 2) The above-prepared slurries with different solid phase contents are sprayed into a temperature field with a distribution of temperature and longitudinal height in a wave-like downward curve toward the bottom of the inner cylinder through a simple spray device to freeze, then collect the microspheres, and Freeze-dry for 24 hours under the condition of -55°C and 10Pa air pressure, among which, the spray height is 160mm, the amount of liquid nitrogen provided is 600mL, and several horizontal circular baffles are used in the liquid nitrogen container; 4 horizontal baffles are used The plate divides the inner cylinder into five areas of equal volume and does not interfere ...

Embodiment 3

[0052] 1) Mix hydroxyapatite powder (particle size about 0.3 μm) with deionized water at a mass ratio of 1:20, ball mill for 24 hours, and then add 1.5wt.% PVA aqueous solution (1wt of the total mass of the slurry .%), and then ball milled for 1h to prepare a slurry with a solid content of 5wt.%.

[0053] 2) Spray the above-prepared slurries with different solid content through a simple spray device into a temperature field with a distribution of temperature and longitudinal height in a wave-like downward curve toward the bottom of the inner cylinder for freezing, and then collect the frozen particles. The balls were freeze-dried for 24 hours at -45°C and the air pressure was 10Pa. The spray height was 270mm, and the amount of liquid nitrogen provided was 1120mL. Several horizontal circular baffles were used in the liquid nitrogen container. Four transverse baffles are used to divide the inner cylinder into five areas of equal volume and do not interfere with each other, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com