Safe disposal and resourceful utilization system for energetic material and implementation method

A resource-based and safe technology, applied in the field of safe disposal of energetic materials and resource-based utilization systems, can solve problems such as small consumption, cumbersome separation process, and no

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

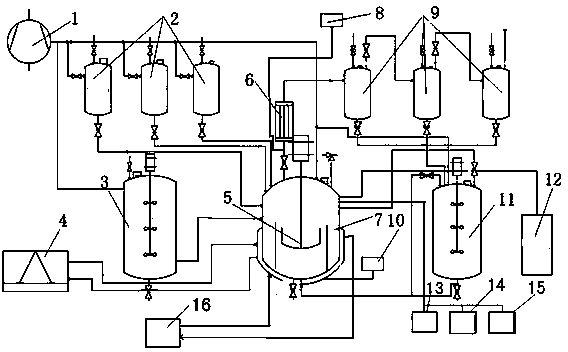

[0161] The safe disposal and resource utilization system of energetic materials includes: gas detection device 8, batching tank 3, reaction tank 7, feeding tank 2, overflow recovery tank 11, gas recovery tank 9, compressor unit 1, heating device 16, refrigeration Unit 4, gas condensing device 6, ultrasonic generator 10, stirring device driven by a motor 5, temperature test automatic control device 12, pressure test device 14, pH test automatic control device 13, ion concentration detection device 15;

[0162] The batching tank 3 has a feed inlet, an air inlet, an air outlet, and a feed outlet; the feed outlet of the batching tank 3 is connected to the reaction tank 7 through a pipeline;

[0163] There are three feeding tanks 2, and these three feeding tanks 2 are used to hold acid liquid, lye, and sulfide. Each feeding tank 2 has a feed inlet, an air outlet, an air inlet, and a feed outlet respectively. The discharge port of the feeding tank 2 is connected with the reaction ta...

Embodiment 2

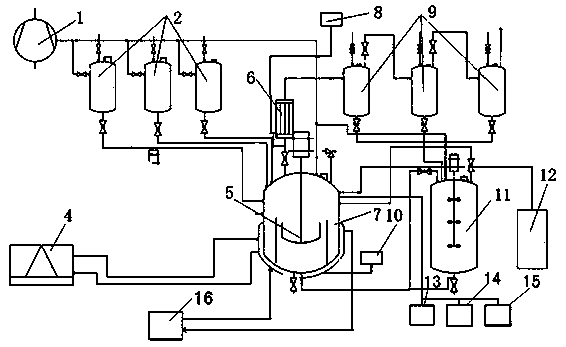

[0185] The difference with Example 1 is that in Example 2, no special batching tank 3 is set, and the batching and reaction are carried out in the reaction tank 7 simultaneously; the specific structure is as follows:

[0186] The safe disposal and resource utilization system of energetic materials includes: gas detection device 8, reaction tank 7, feeding tank 2, overflow recovery tank 11, gas recovery tank 9, compressor unit 1, heating device 16, refrigeration unit 4, gas Condensing device 6, ultrasonic generator 10, stirring device 5 driven by motor, temperature test automatic control device 12, pressure test device 14, pH test automatic control device 13, ion concentration detection device 15;

[0187] There are three feeding tanks 2, and these three feeding tanks 2 are used to hold acid liquid, lye, and sulfide. Each feeding tank 2 has a feed inlet, an air outlet, an air inlet, and a feed outlet respectively. The discharge port of the feeding tank 2 is connected with the r...

Embodiment 3

[0200] Adopt the equipment of embodiment 1, in following embodiment, if relate to batching tank 3, all adopt the equipment of embodiment 1, if not relate to batching tank 3, then adopt the equipment of embodiment 2.

[0201] When the energetic material is a single-base propellant, the realization method of the safe disposal and resource utilization system includes the following steps:

[0202] (1) Preparation of reaction materials:

[0203] Prepare single-base propellant, conversion agent, and prepare hydrolyzate;

[0204] Prepare single-base propellant: crush the energetic material to a fineness of 60 mesh;

[0205] Prepare the hydrolyzate: prepare the hydrolyzate NaOH in the batching tank 3, the concentration is 20%, when preparing the lye, stir while preparing, and the control stirring speed is 100rpm;

[0206] Prepare the conversion agent: the conversion agent is potassium humate, and its concentration is: 15%;

[0207] (2) Feeding

[0208] Add the single-base propella...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com