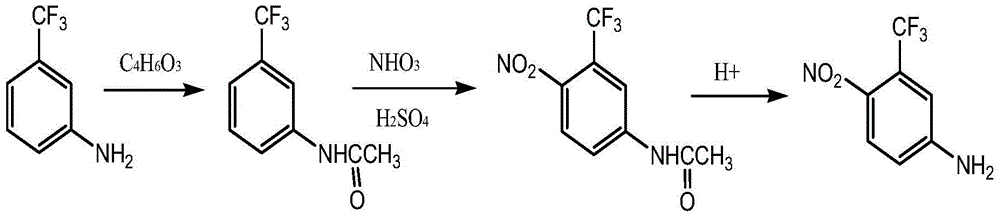

Process for synthesizing flutamide

A synthesis process and flutamide technology, applied in the field of flutamide synthesis technology, can solve the problems of complex recrystallization, difficult quality control, complex production process and the like, and achieve high catalyst activity, few impurities and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

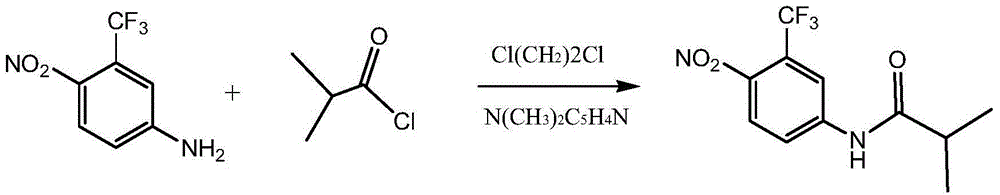

Method used

Image

Examples

Embodiment 1

[0030] A kind of synthetic technique of flutamide, comprises the following steps:

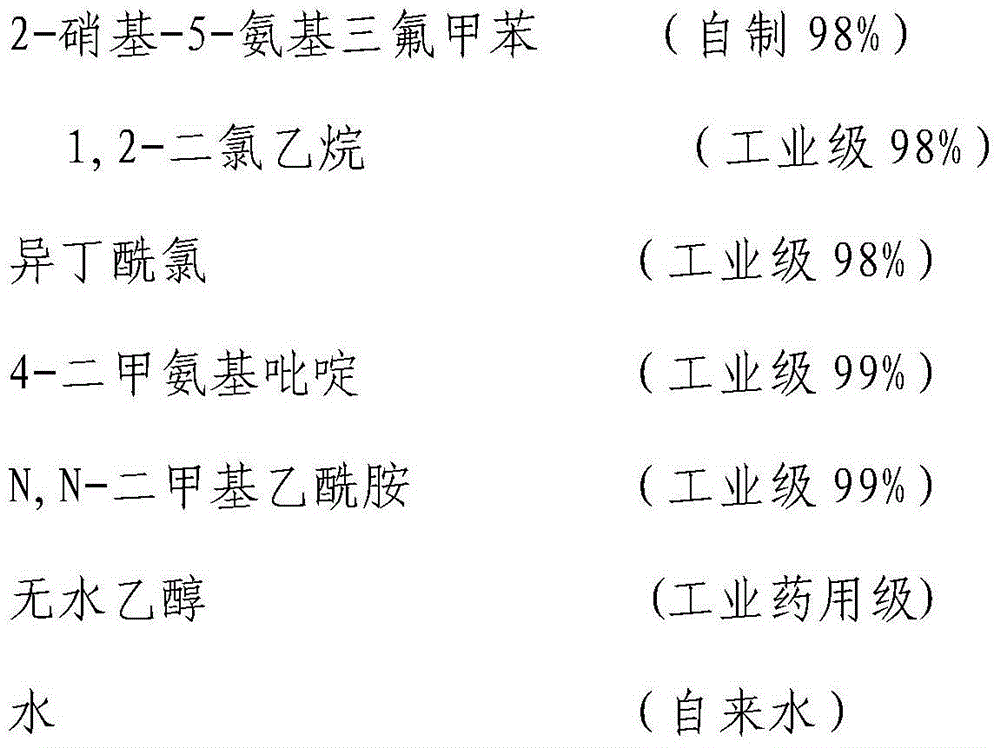

[0031] a) In a 250mml reaction flask equipped with a stirrer, a thermometer, a dropping funnel and a reflux dehydration device, add 40mml of 1,2-dichloroethane and 10mml of N,N-dimethylacetamide, and add them under stirring 20g of 2-nitro-5-aminotrifluorotoluene and 1.46g of 4-dimethylaminopyridine, slowly add 12.2g of isobutyryl chloride dropwise under ice-water bath conditions at a controlled temperature of 5-10°C, the yellow solution gradually becomes cloudy, and the dropwise addition is completed , remove the ice-water bath, keep the temperature at 18-25°C and stir for a period of time, take samples and monitor the reaction by TLC until the reaction of 2-nitro-5-aminotrifluorotoluene is completely completed;

[0032] b) Change the oil bath, add 60mml of water into the reaction flask, stir to raise the temperature, control the temperature of the oil bath to 105-120°C, reflux to remove the 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com