ABS/PBT alloy material and preparation method thereof

A technology of alloy material and formula, which is applied in the field of ABS/PBT alloy material and its preparation, can solve the problems of poor compatibility between ABS and PBT, PBT cannot achieve the modification effect, etc., and achieve high scratch resistance and excellent physical comprehensive performance , The effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

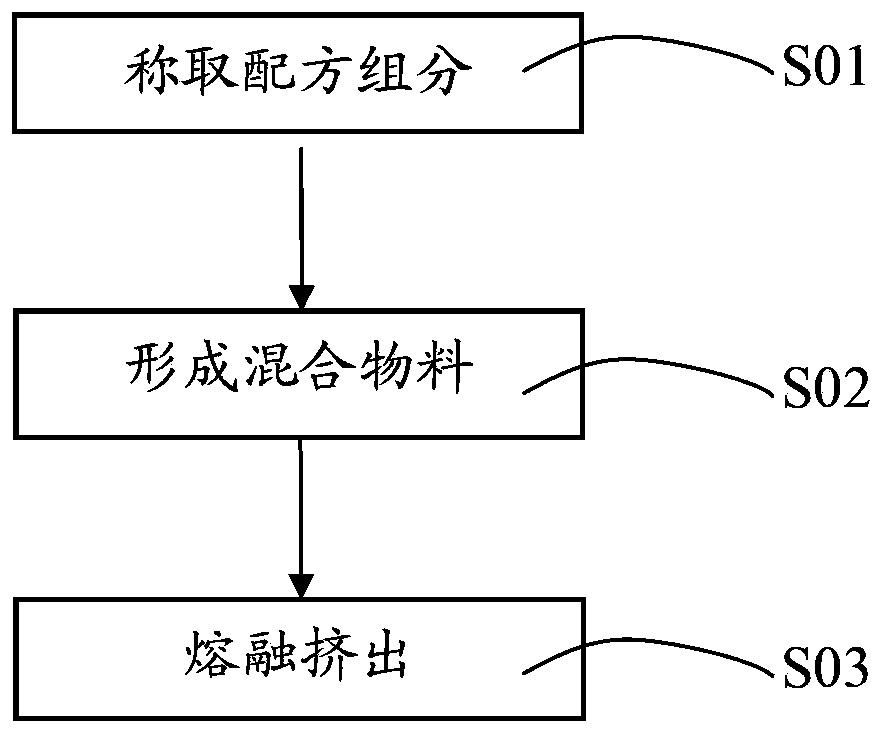

[0039] The preparation method of the above-mentioned ABS / PBT alloy material fully mixes ABS, PBT, compatibilizer, anti-scratch agent and other additives through the method of melt extrusion and synergizes, thereby endowing the ABS / PBT alloy material with excellent It has the characteristics of high impact resistance, scratch resistance and good compatibility. The preparation method has simple process, does not need to add complex equipment, has low cost, improves the performance of the composite polymer material, and is suitable for industrialized production.

[0040] Now in conjunction with specific examples, the ABS / PBT alloy material of the embodiment of the present invention and its preparation method will be further described in detail.

Embodiment 1

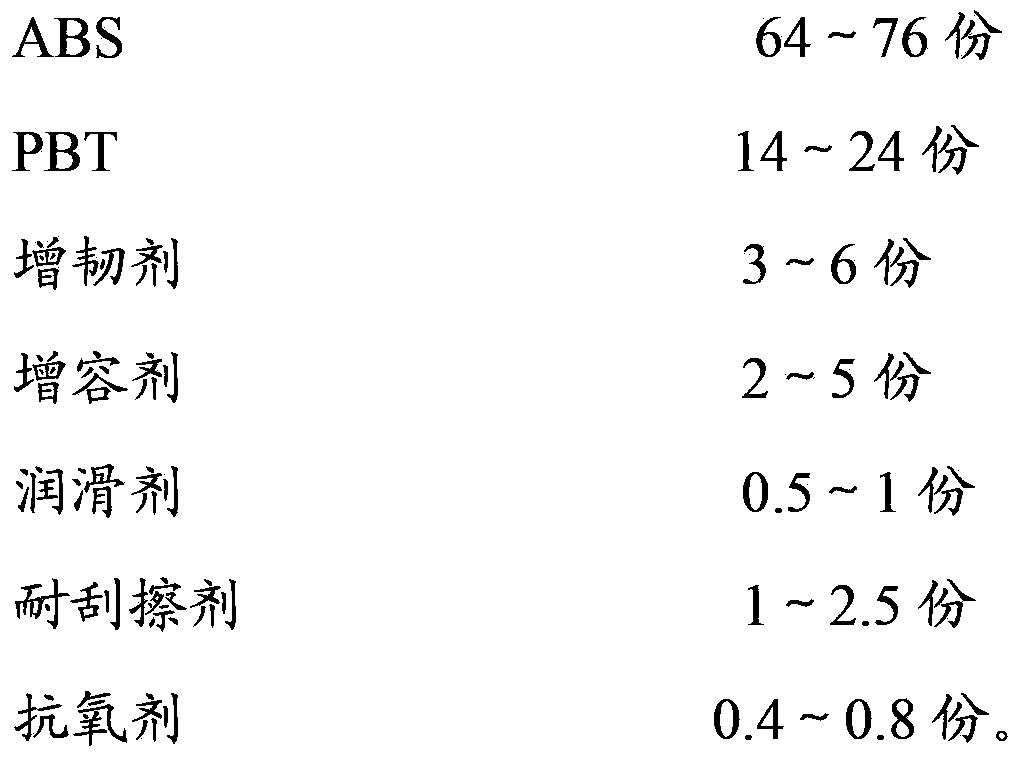

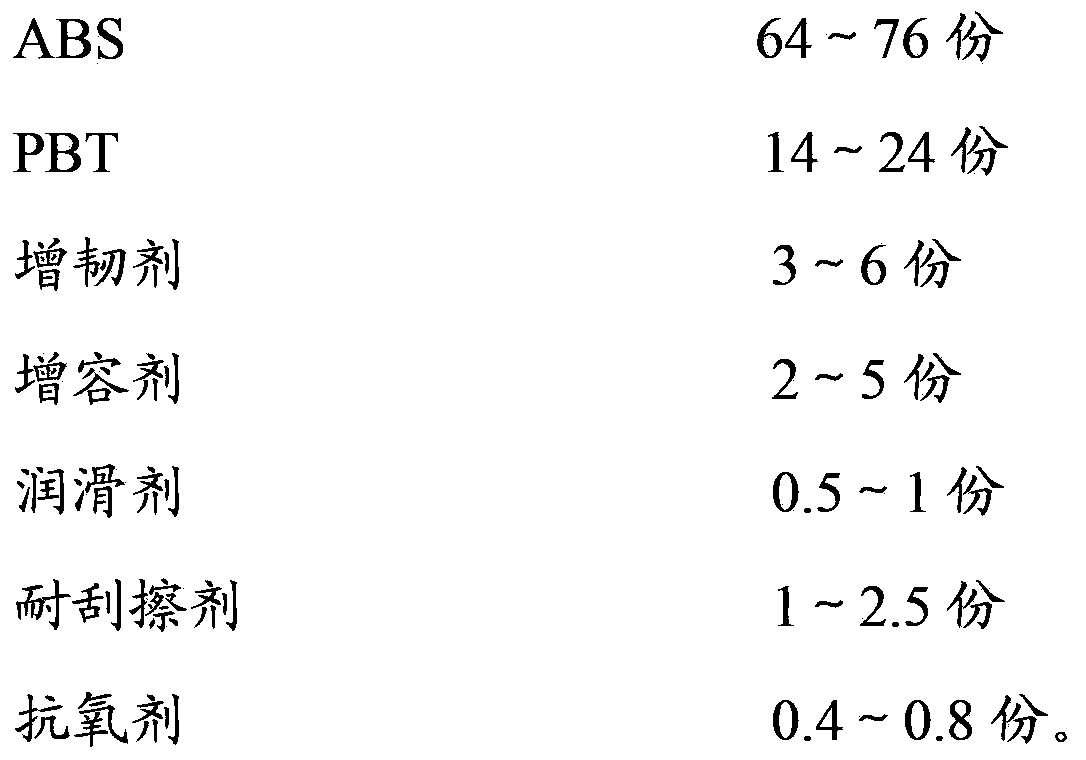

[0042] A kind of ABS / PBT alloy material, comprises the formula component of following weight part:

[0043]

[0044]

[0045] The preparation method of this ABS / PBT alloy material is as follows:

[0046] S11. Dry acrylonitrile-butadiene-styrene in an oven at 80°C for 4 hours, and dry polybutylene terephthalate in an oven at 100°C for 4 hours;

[0047] S12. Weigh each raw material formula according to the ratio of the above-mentioned parts by weight, and mix in a high-speed mixer for 8 minutes to obtain a mixed material;

[0048] S13. Extrude and granulate the mixed material mixed in step S12 in a twin-screw extruder, wherein the temperature at the feed end is 160°C, the temperature in the first zone is 200°C, the temperature in the second zone is 215°C, and the temperature in the third zone The temperature is 225°C, the temperature in the fourth zone is 225°C, the head is 205°C, the residence time is 2min, and the pressure is 12MPa; ABS / PBT alloy material is obtained. ...

Embodiment 2

[0050] A kind of ABS / PBT alloy material, comprises the formula component of following weight part:

[0051]

[0052] The preparation method of this ABS / PBT alloy material is as follows:

[0053] S21. Dry acrylonitrile-butadiene-styrene in an oven at 80°C for 4 hours, and dry polybutylene terephthalate in an oven at 100°C for 4 hours;

[0054] S22. Weigh each raw material formula according to the ratio of the above-mentioned parts by weight, and mix in a high-speed mixer for 6 minutes to obtain a mixed material;

[0055] S23. Extrude and granulate the mixed material mixed in step S22 in a twin-screw extruder, wherein the temperature at the feed end is 170°C, the temperature in the first zone is 210°C, the temperature in the second zone is 225°C, and the temperature in the third zone The temperature is 235°C, the temperature in the fourth zone is 235°C, the head is 215°C, the residence time is 2min, and the pressure is 11MPa; ABS / PBT alloy material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com