Moisture-proof environment-friendly shoe polish and preparation method thereof

A shoe polish, environmental protection technology, applied in the directions of botanical equipment and methods, chemical instruments and methods, chemicals for biological control, etc. Fragrant, good moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

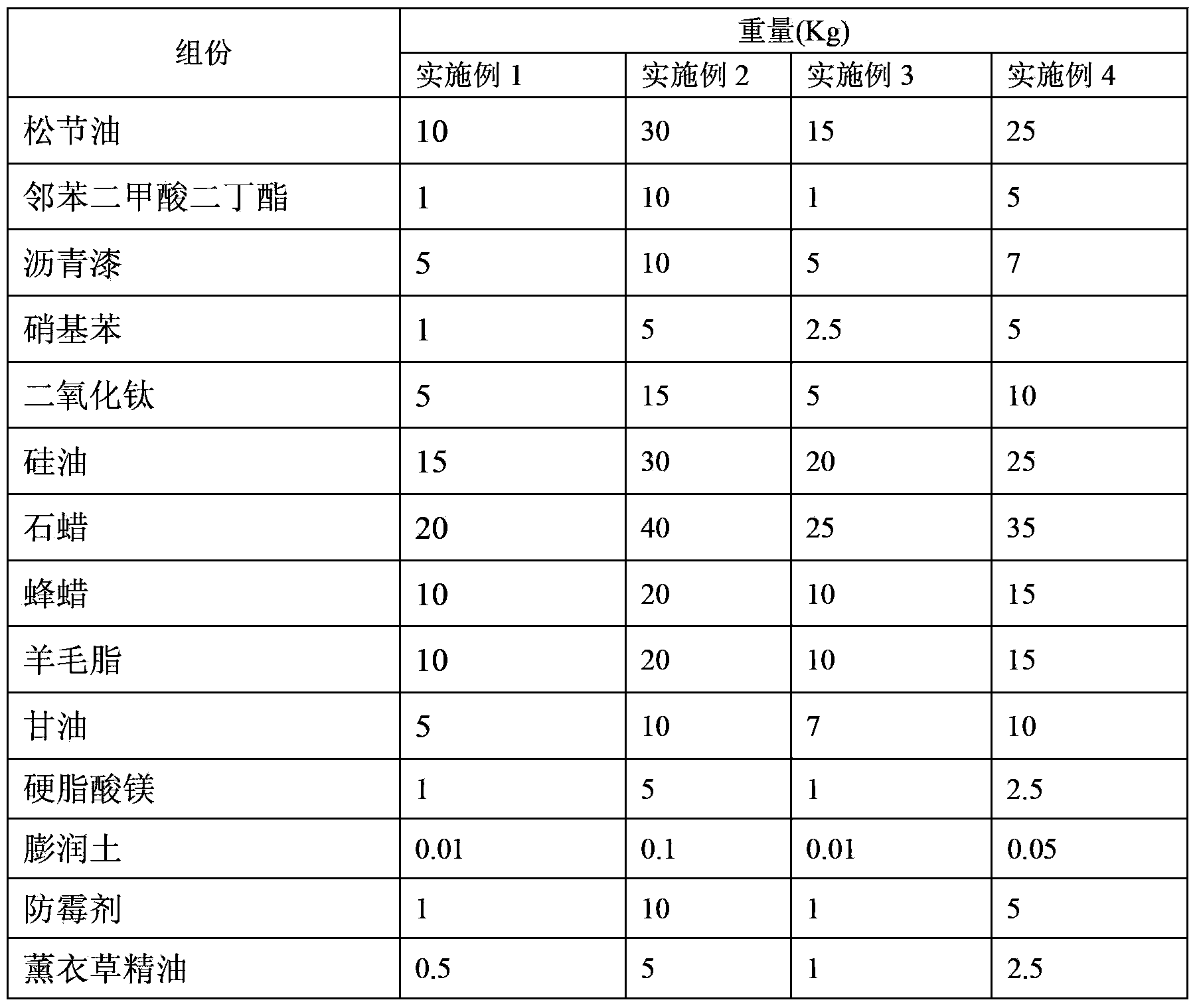

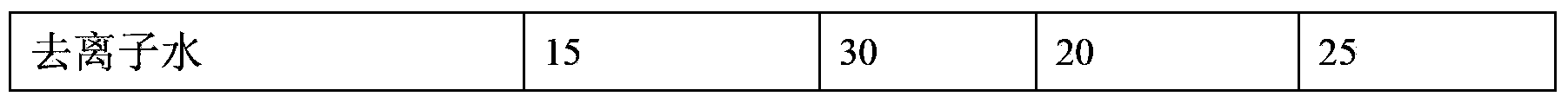

Examples

Embodiment 1

[0022] (1) Heat turpentine, dibutyl phthalate, asphalt varnish, nitrobenzene, silicone oil, paraffin, beeswax, and lanolin at 115°C while stirring, and after melting, mixture A is obtained;

[0023] (2) Heat, stir, and mix titanium dioxide, glycerin, magnesium stearate, and deionized water at 70°C to obtain mixture B;

[0024] (3) Add mixture B to mixture A, stir, mix, let cool to 80°C, add bentonite, phenol, lavender essential oil, stir evenly, and the product is ready.

Embodiment 2

[0026] (1) Heat turpentine, dibutyl phthalate, asphalt varnish, nitrobenzene, silicone oil, paraffin, beeswax, and lanolin at 125°C while stirring, and after melting, mixture A is obtained;

[0027] (2) Heat, stir, and mix titanium dioxide, glycerin, magnesium stearate, and deionized water at 80°C to obtain mixture B;

[0028] (3) Add mixture B to mixture A, stir, mix, let cool to 90°C, add bentonite, pentachlorophenol, lavender essential oil, stir evenly, and the product is ready.

Embodiment 3

[0030] (1) Heat turpentine, dibutyl phthalate, asphalt varnish, nitrobenzene, silicone oil, paraffin, beeswax, and lanolin at 118°C while stirring, and after melting, mixture A is obtained;

[0031] (2) Heat, stir, and mix titanium dioxide, glycerin, magnesium stearate, and deionized water at 75°C to obtain mixture B;

[0032] (3) Add mixture B to mixture A, stir, mix, let cool to 85°C, add bentonite, phenol, lavender essential oil, stir evenly, and the product is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com