A kind of improved betaine surfactant composition system and its application

A surfactant and betaine technology, applied in the field of oil field development, can solve the problems of unstable decomposition of surfactants and polymers, the inability to popularize mass production of industrial products, limit the selection of surfactants and polymers, and achieve savings The effect of time and investment, great practical significance and economic benefits, and the significance of protecting natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 A-1C

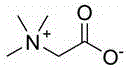

[0045] In these examples, we compare the individual efficacy (A and B) of two betaine surfactants of the same type, and the efficacy of their mixed system (C). Betaine surfactant A is lauryl dimethyl betaine, and its lipophilic group has a carbon number of about 12. Betaine surfactant B is oleyl dimethyl betaine, and its lipophilic group has a carbon number of about 18. They are both alkyl dimethyl betaine surfactants.

Embodiment 1A

[0047] Take 50 grams of lauryl dimethyl betaine (from Western Surfactants Research and Development Center, USA, with 30% effective concentration, pH 6.0 -7.0) 50 grams of deionized water; add the above into a beaker , And then stir evenly at room temperature with an electromagnetic stirrer. Adjust the pH to 7-8 with sodium hydroxide and acetic acid. The formed surfactant system is a uniform transparent liquid.

[0048] Crude oil: It comes from oil fields in Northeast China. The crude oil presents high acidity and high aromatic content.

[0049] Test instrument: TX-500C interfacial tension.

[0050] Test conditions: (1) The temperature is 55 degrees Celsius; (2) The reinjection water contains 4000 mg / L of salinity; (3) Polymer: None; (4) The dilution concentration of the surfactant system: 0.05% (equivalent to Dimethyl betaine diluted 2000 times to use).

[0051] Test result: when the dilution concentration of the surfactant system is 0.05%, the measured oil-water interfacial tension ...

Embodiment 1B

[0054] Take 50 grams of oleyl dimethyl betaine (from Western Surfactants Research and Development Center, USA, with a 30% effective concentration of pH 6.0 -7.0); 50 grams of deionized water; add the above into a beaker , And then stir evenly at room temperature with an electromagnetic stirrer. Adjust the pH to 7-8 with sodium hydroxide and acetic acid. The formed surfactant system is a uniform transparent liquid.

[0055] Crude oil: It comes from oil fields in Northeast China. The crude oil presents high acidity and high aromatic content.

[0056] Test instrument: TX-500C interfacial tension.

[0057] Test conditions: (1) temperature 55 degrees Celsius; (2) reinjection water with a salinity of 4000 mg / L; (3) polymer: none; (4) dilution concentration of surfactant system: 0.05%.

[0058] Test result: when the dilution concentration of the surfactant system is 0.05%, the measured oil-water interfacial tension is 1.4×10 -3 dyn / cm.

[0059] Experiments show that oleyl dimethyl betaine ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com