Construction method of flexible leveling system of ceilings

A construction method and flexible technology, applied in covering/lining, construction, building structure, etc., can solve the problems of slow setting and hardening of cement mortar, inability to adapt to needs, long construction process, etc., achieving less ash, fast construction, and construction period. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

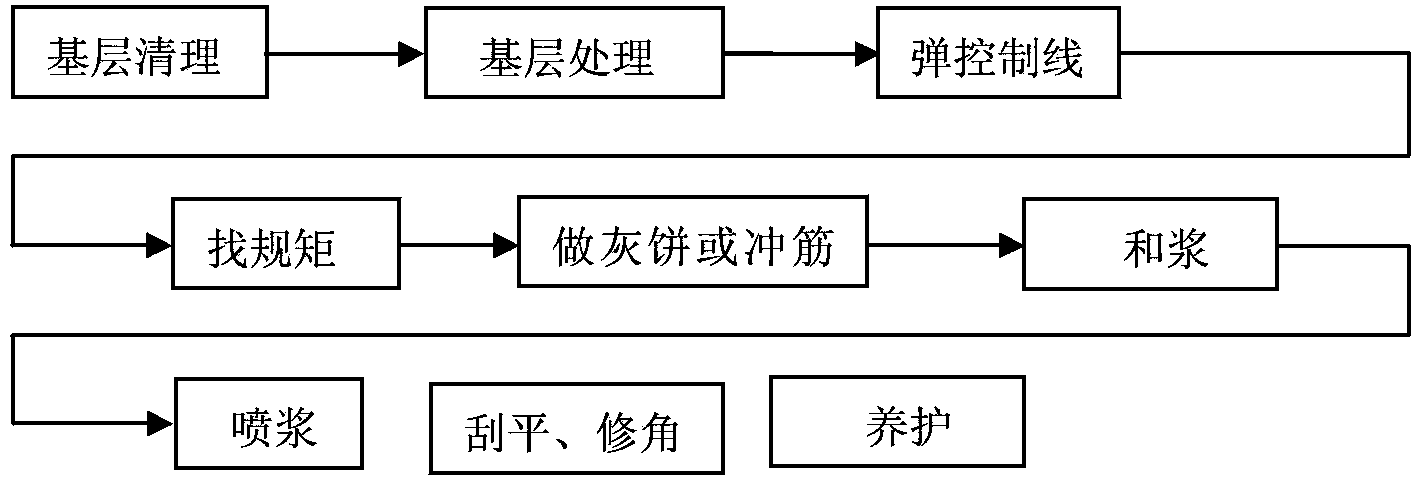

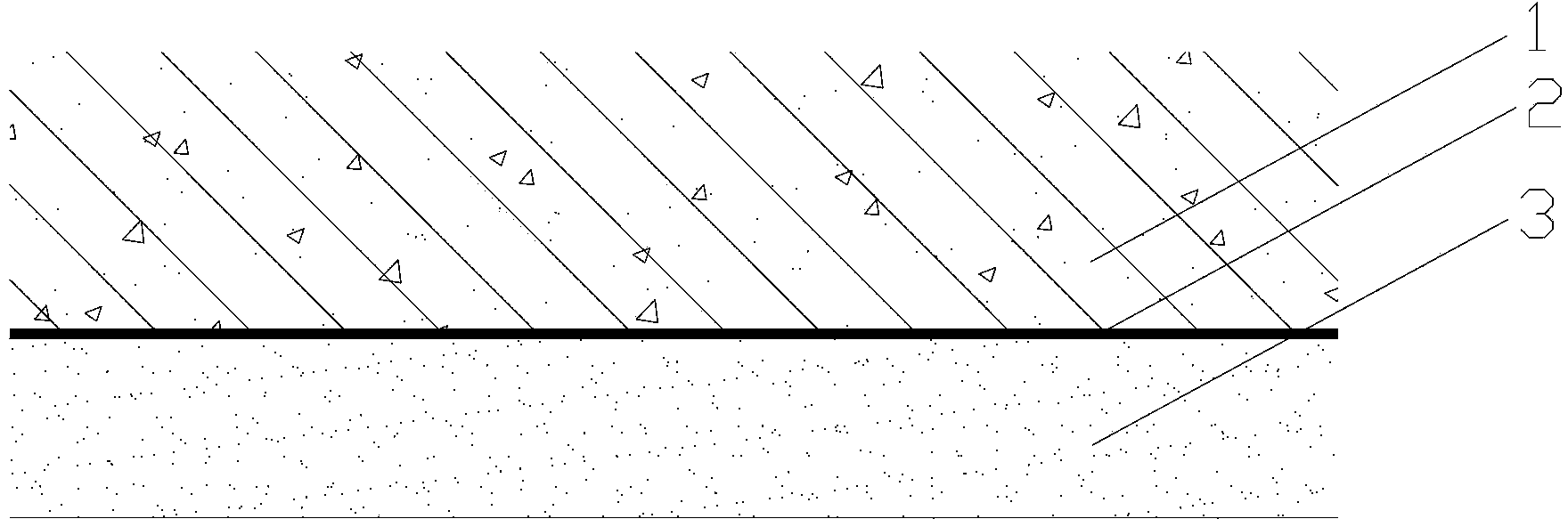

[0029] Such as Figure 1-2 As shown, the construction method of a ceiling flexible leveling system described in the embodiment of the present invention, its detailed steps are as follows:

[0030] Operating conditions: 1. The site temperature is 5-40 degrees Celsius. 2. The pipeline laying construction of strong and weak electricity in the ceiling has been completed. 3. Set +500mm horizontal line around the wall. 4 There are no sundries and materials piled up on the ground in the construction area. 5 The base has passed the civil engineering inspection, and there is no other vibration operation during construction and maintenance. 6 Water and electricity are connected to the site, and vertical transportation is convenient. The construction electricity requirement is three-phase electricity.

[0031] Construction preparation: According to the design elevation, take the +500mm horizontal line as the benchmark, and pop up the top elevation control line 0.20m below the top ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com