Manufacturing process of three-layer one-way see-through film printing material

A printing material, one-way perspective technology, applied in the directions of lamination, printing, layered products, etc., can solve the problems of affecting the appearance, inability to absorb ink, low thermal bonding efficiency, etc., to achieve excellent flatness and stiffness, raw materials The effect of improved utilization and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

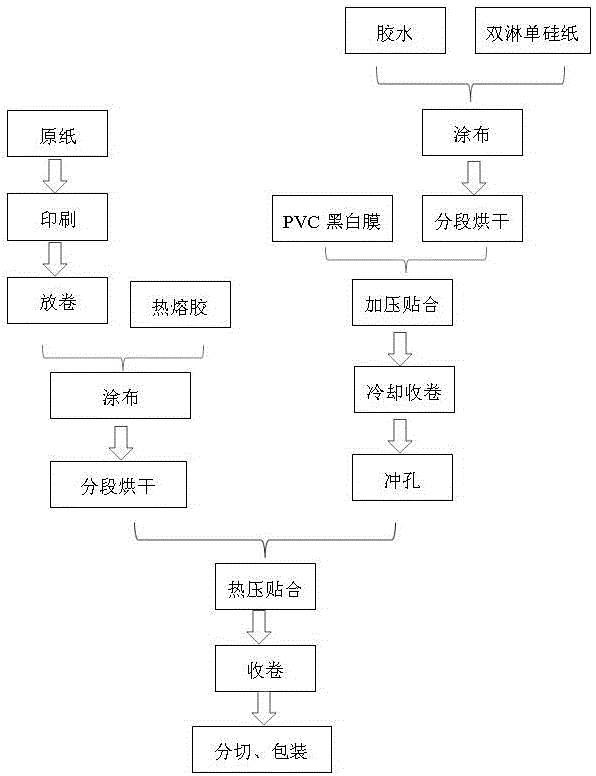

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

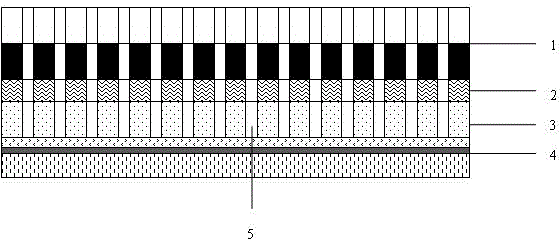

[0036] Such as figure 1 Shown: the layered structure of PVC black and white film layer 1, glue layer 2, double drenched single silicon paper 3, and hot melt adhesive paper 4, PVC black and white film 1, glue layer 2, double drenched single silicon paper 3 The light-transmitting through-holes 5 are regularly arranged on the vertical plane.

[0037] Its manufacturing process includes the following steps:

[0038] 1. Production of hot melt adhesive paper

[0039] 1) Print dark ink on base paper with anilox roller;

[0040] 2) Put the large roll of printed base paper on the roll of the adhesive machine and unwind it;

[0041] 3) Coating low softening point solvent-based hot melt adhesive on the printing surface;

[0042] 4) Sectional drying, the drying temperature is 60°C;

[0043] 5) Rewinding;

[0044] 2. PVC black and white film adhesive and punching

[0045] 6) Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com