High-temperature hydrothermal mixing synthesis method for vanadium dioxide powder

A vanadium dioxide, high-temperature mixing technology, applied in vanadium oxide, nanotechnology for materials and surface science, nanotechnology, etc., to achieve wide application prospects, good crystallinity, and good morphology

Inactive Publication Date: 2013-12-04

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the metastable phase VO was synthesized by the hydrothermal high-temperature mixing method. 2 (B), metastable phase VO 2 (A), stable VO 2 (M) or VO 2 (R) powder has not been reported

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0051] Embodiment two:

Embodiment 2

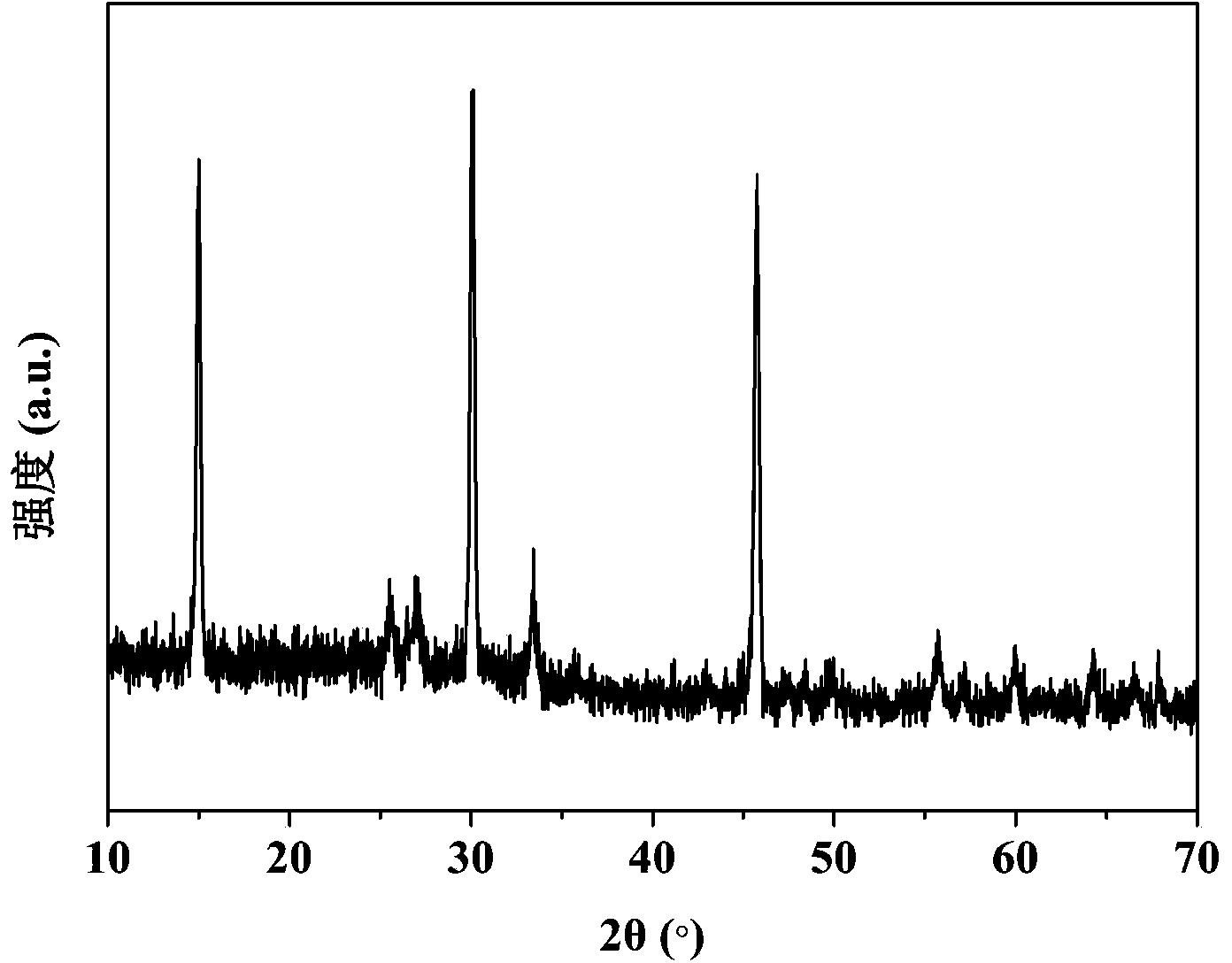

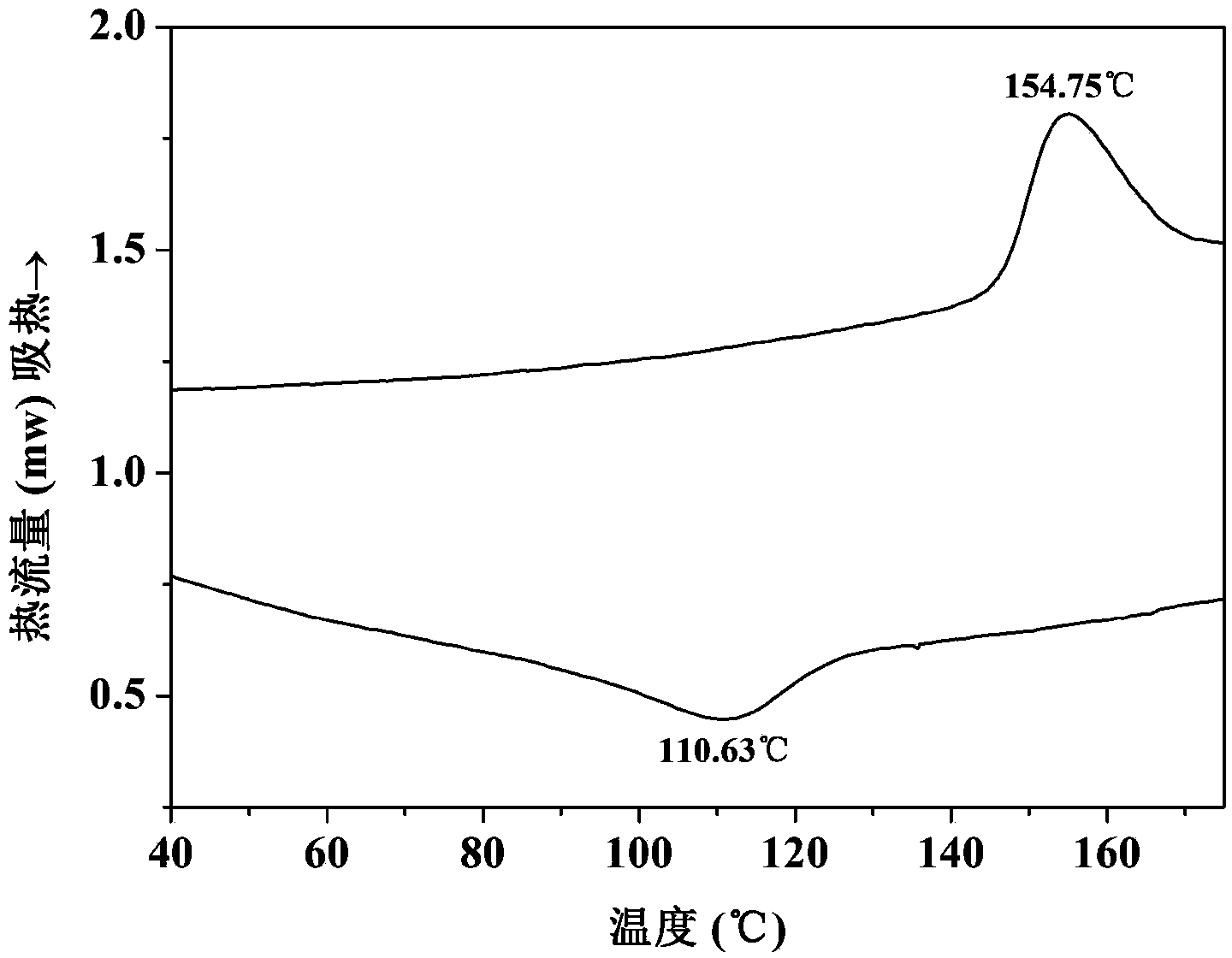

[0053] The VO synthesized by embodiment one or embodiment two by hydrothermal high temperature mixing method 2 (B) or VO 2 (A) The powder is put into a tube furnace and annealed at 600°C for 4h under the protection of Ar atmosphere to obtain VO 2 (R) / (M) powder.

[0054]

[0055] Embodiment three:

Embodiment 3

[0057] Embodiment four:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-temperature hydrothermal mixing synthesis method for vanadium dioxide powder. Raw materials are separated in the temperature rise process of synthetic powder, when the temperature rises to the reaction temperature of 100-260 DEG C, the raw materials are mixed, then reaction is performed, a reaction kettle is rotated while heat insulation is carried out, and the heat insulation continues for 4-48 hours. The vanadium dioxide powder synthesized by the high-temperature hydrothermal mixing synthesis method inherits all advantages of vanadium dioxide powder synthesized by the hydrothermal mixing synthesis method, is simple in process and low in energy consumption, and avoids producing interphase impurities in the temperature rise process of the hydrothermal method, so that powder with higher purity and better crystallinity can be obtained and the high-temperature hydrothermal mixing synthesis method for vanadium dioxide powder has a very wide application prospect.

Description

technical field [0001] The invention belongs to the field of functional materials, and relates to a method for synthesizing metastable phase VO by hydrothermal high-temperature mixing 2 (B), metastable phase VO 2 (A), stable VO 2 (M) or VO 2 (R) Powder method. [0002] Background technique [0003] Since scientists first discovered VO in 1959 2 Since it has phase change properties, about VO 2 research has been attracting people's attention. where VO 2 The reversible phase transition of (R) / (M) phase is the earliest and most systematic direction studied, because the R / M phase will undergo metal-semiconductor transition (MST) at 341K (68°C), this reversible The first-order phase transition not only has a fast response speed, but also is accompanied by sudden changes in resistivity, magnetic susceptibility, and optical transmittance during the phase transition process, especially in the infrared light band. The variable temperature is closest to room temperature. Ther...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G31/02B82Y30/00

Inventor 朱孔军裘进浩刘鹏程古其林郑红娟

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com