Fertilizer quick-acting long-acting synergist

A synergist and quick-acting technology, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of increasing the burden on farmers, single raw materials, and not rigorous enough, so as to improve the effective utilization rate, huge economic benefits, and maintain long-term effective Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] A quick-acting and long-acting synergist for fertilizers, the ratio of raw materials by weight is: 6 parts of 2.4 sodium dinitrophenolate, 12 parts of sodium p-nitrophenolate, 14 parts of sodium o-nitrophenolate, 7 parts of polyaspartic acid, 8 parts of polyglutamic acid, 7 parts of hydroquinone, 14 parts of thiourea, 4 parts of pyrazole dimethyl phosphate, 7 parts of acrylamide, 12 parts of dicyandiamide, 4 parts of N-J butylthiophosphoric triamide, 2 parts - 1 part of methoxy-5-nitrophenol, 5 parts of sodium a-naphthalene acetate, 2 parts of 6-benzylaminopurine, 3 parts of humic acid, and 3 parts of potassium hydroxide.

[0011] The raw materials are weighed according to the above proportions, crushed and passed through a 20-35 mesh sieve, and the obtained raw material powders are mixed and stirred to obtain the product.

Embodiment 2

[0013] A quick-acting and long-acting synergist for fertilizers, the weight ratio of raw materials is: 7 parts of 2.4 sodium dinitrophenolate, 14 parts of sodium p-nitrophenolate, 17 parts of sodium o-nitrophenolate, 9 parts of polyaspartic acid, 7 parts of polyglutamic acid, 8 parts of hydroquinone, 18 parts of thiourea, 4 parts of pyrazole dimethyl phosphate, 5 parts of acrylamide, 8 parts of dicyandiamide, 7 parts of N-J butylthiophosphoric triamide, 2 -3 parts of methoxy-5-nitrophenol, 3 parts of sodium a-naphthalene acetate, 1 part of 6-benzylaminopurine, 5 parts of humic acid, and 2 parts of potassium hydroxide.

[0014] The raw materials are weighed according to the above proportions, crushed and passed through a 20-35 mesh sieve, and the obtained raw material powders are mixed and stirred to obtain the product.

Embodiment 3

[0016] A quick-acting and long-acting synergist for fertilizers, the ratio of raw materials in parts by weight is: 8 parts of 2.4 sodium dinitrophenolate, 11 parts of sodium p-nitrophenolate, 16 parts of sodium o-nitrophenolate, 12 parts of polyaspartic acid, 8 parts of polyglutamic acid, 7 parts of hydroquinone, 14 parts of thiourea, 2 parts of pyrazole dimethyl phosphate, 5 parts of acrylamide, 8 parts of dicyandiamide, 3 parts of N-J butylthiophosphoric triamide, 2 parts -3 parts of methoxy-5-nitrophenol, 6 parts of sodium a-naphthalene acetate, 6 parts of 6-benzylaminopurine, 6 parts of humic acid, and 1 part of potassium hydroxide.

[0017] The raw materials are weighed according to the above proportions, crushed and passed through a 20-35 mesh sieve, and the obtained raw material powders are mixed and stirred to obtain the product.

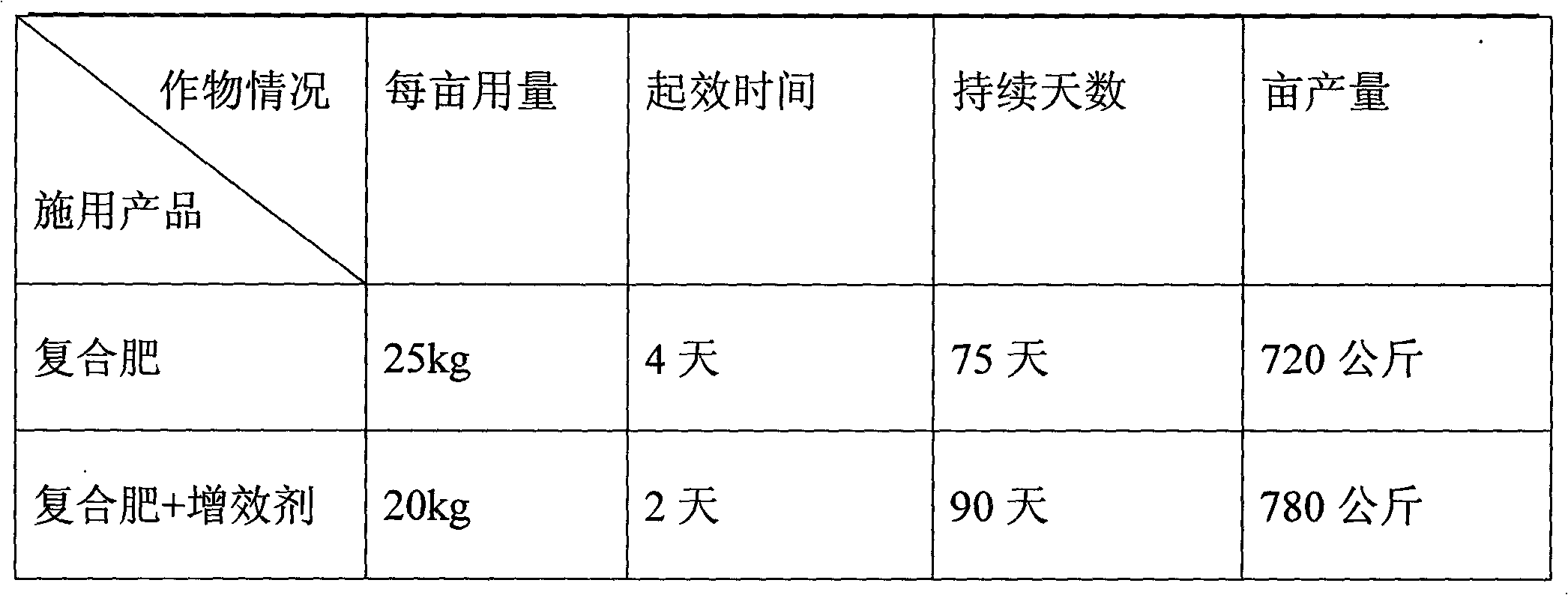

[0018] In use, every 50 kilograms of fertilizer is mixed with about 1 kilogram of the synergist of the present invention, stirred evenly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com