Annular kiln type dry type biogas fermentation method

A dry fermentation and wheel kiln technology, which is applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of slow fermentation speed and inability to continue production in circular operation, so as to achieve fast fermentation speed and resource utilization , the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

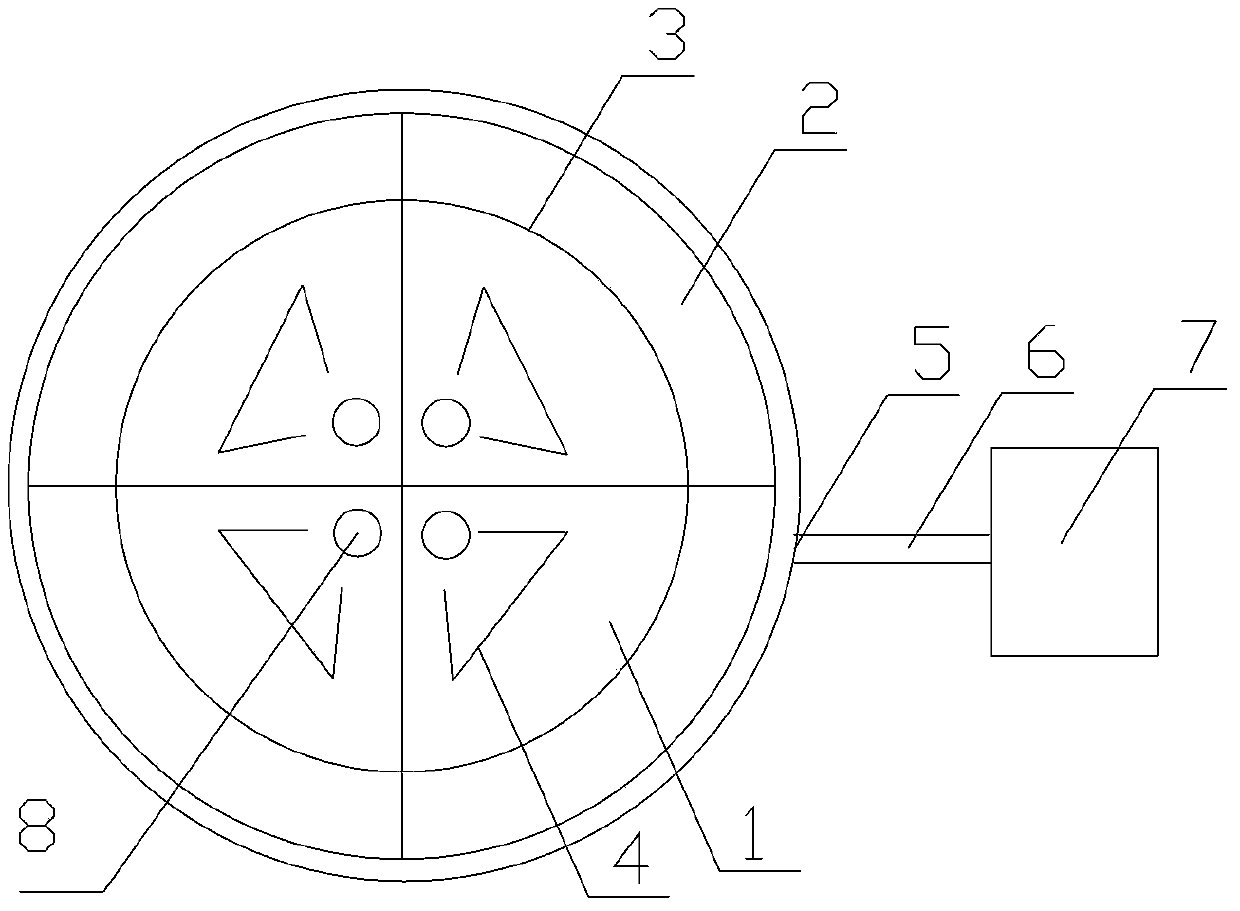

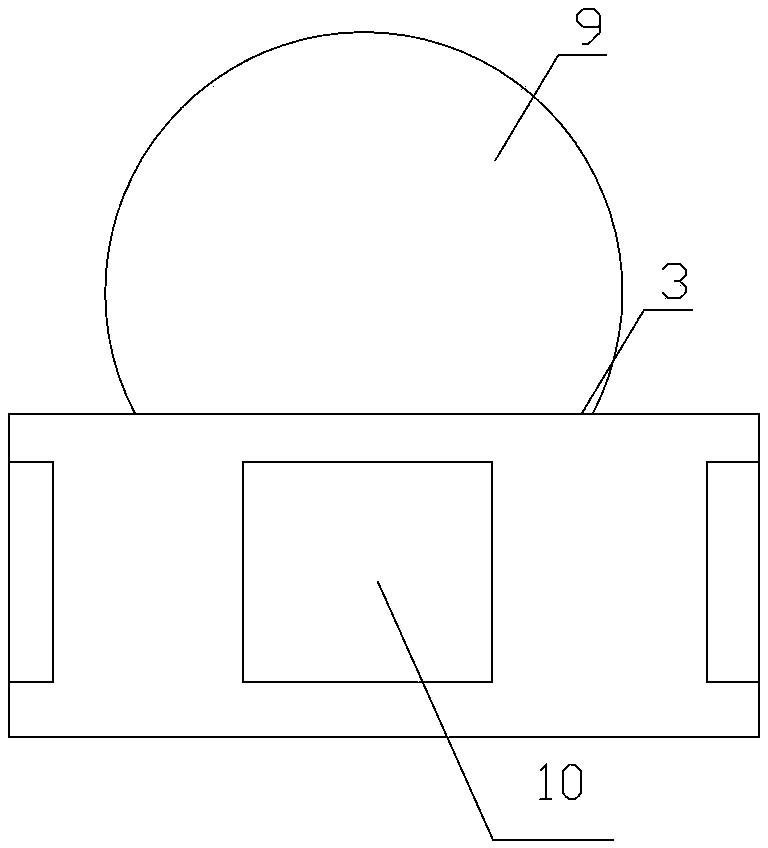

[0016] as attached figure 1 , 2 As shown, a wheel kiln type biogas dry fermentation device is first disclosed, which is characterized in that it is mainly composed of a wheel kiln type fermentation room 1 separated by a circular fermentation room, and the wheel kiln type fermentation room is composed of a round The circular fermentation room is divided into 4 or 6 rooms radially from the center of the circle. The diameter of the circular fermentation room is 600cm, and the height is 200 to 300cm. Between the outer rings of the circular fermentation room is a circular feed inlet 2; an air storage bag 9 for storing biogas is installed on the dome, and a gas supply pipeline and a valve are installed on the air storage bag; in each wheel kiln type fermentation room 1 There is a ventilation hole 8 on the dome 3 between the top and the air storage bag, and a one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com