Acid mist recycling system device

A recovery system and acid mist technology, applied in the direction of photography technology, equipment, photography auxiliary technology, etc., to achieve the effect of saving resources and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

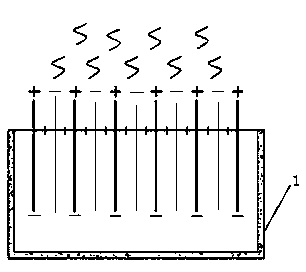

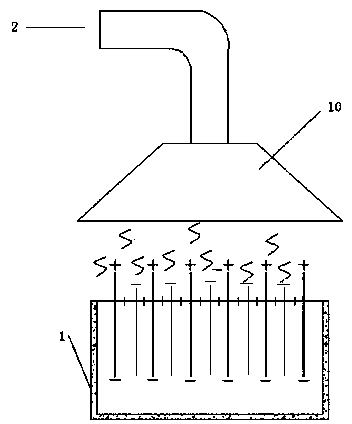

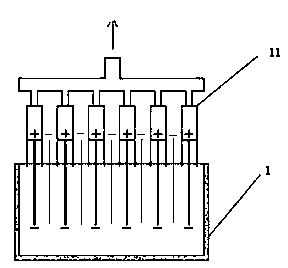

[0043] In the process of electrolytic nickel or cobalt, the anode will produce a lot of oxygen-containing acid mist, if these acid mist is not discharged in time, it will seriously affect the health of workers and corrode the plant equipment. Therefore, an acid mist recovery system device is added to the electrolytic nickel or electrolytic cobalt system device, and the system also includes an acid mist absorption tower. Both the cathode frame and the anode frame are set in the electrowinning cell, and a permeable membrane is set between the cathode frame and the anode frame. The electrolyte inlet is set on the cathode frame, so the electrolyte in the electrowinning cell enters the cathode frame from the electrolyte inlet, and passes through the permeable membrane set between the cathode frame and the anode frame, and enters the anode frame through the permeation of the permeable membrane. Complete the electrowinning process.

[0044] The acid mist outlet is set on the anode f...

Embodiment 2

[0048] The generated acid mist enters the ventilation channel through the acid mist outlet, and small holes are opened on the side of the ventilation channel, and the acid mist enters the channel through the small holes, and all of them enter the acid mist absorption tower for treatment under the action of the exhaust fan. Including the circulation tank, the material from the acid mist absorption tower is pumped into the circulation tank, and sodium carbonate is added into the circulation tank to recover the nickel ions mixed in the acid mist for reuse. The principle of absorption is as follows:

[0049] Na 2 CO 3 +H 2 SO 4 = Na 2 SO 4 +CO 2 ↑+H 2 o

[0050] The composition of oxygen acid mist is H 2 SO 4 、NiSO 4 and O 2 , the addition of described sodium carbonate is according to reaction formula H 2 SO 4 +Na 2 CO 3 = Na 2 SO 4 +H 2 O+CO 2 ↑The proportion relationship in the ratio is added after the ratio. The oxygen containing acid mist is treated and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com