L-methionine product content determination method

A technology for measuring methionine, applied in the direction of polarization influence characteristics, etc., can solve the problems of expensive instrument, poor accuracy, high cost, etc., and achieve the effect of cheap instrument and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

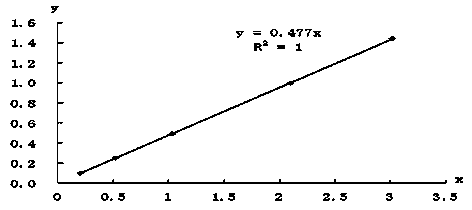

Image

Examples

Embodiment 1

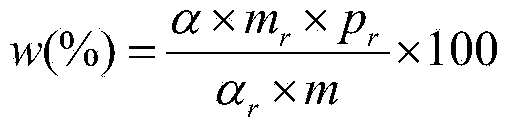

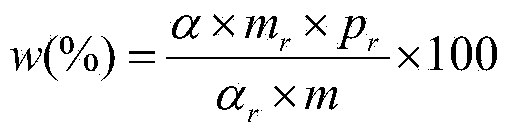

[0025] A kind of assay method of L-methionine product content, it is specifically carried out according to the following steps:

[0026] ① Weigh 2.1154g of L-methionine reference substance with a known mass percentage of 99.0%, put it into a 100mL measuring bottle, add 5mol / L hydrochloric acid solution to dissolve, dilute to 100mL, shake well, and use it as the reference substance solution. And rinse the measuring tube several times with the reference substance solution, then slowly inject the reference substance solution into the measuring tube, place it in the polarimeter to detect the reading, and obtain the optical rotation of the reference substance solution as 0.995°; wherein, the precision of the polarimeter is 0.001°, the length of the optical rotation tube is 2dm, the measurement condition is the D line (589.3nm) of the sodium spectrum, and the temperature is 23°C;

[0027] ②Take an appropriate amount of the product containing at least 90% of the mass percentage of L-...

Embodiment 2

[0045] A kind of assay method of L-methionine product content, the selection of its reference substance and reference substance solution, mensuration are identical with embodiment 1, and other steps are specifically carried out according to the operating steps described in embodiment 1, and in this example , the quality of the sample to be tested is 2.0075g, the optical rotation of the sample solution to be tested is 0.926°, and the calculated result shows that the content of L-methionine in the sample to be tested is 97.09%.

Embodiment 3

[0047] A kind of assay method of L-methionine product content, the selection of its reference substance and reference substance solution, mensuration are identical with embodiment 1, and other steps are specifically carried out according to the operating steps described in embodiment 1, and in this example , the quality of the sample to be tested is 2.0351g, the optical rotation of the sample solution to be tested is 0.948°, and the calculated result shows that the content of L-methionine in the sample to be tested is 98.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com