A Raman non-destructive testing method for the quality of frozen Penaeus vannamei

A non-destructive testing and white shrimp technology, applied in Raman scattering, test sample preparation, material excitation analysis, etc., can solve problems affecting product quality, muscle freezing denaturation, quality decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

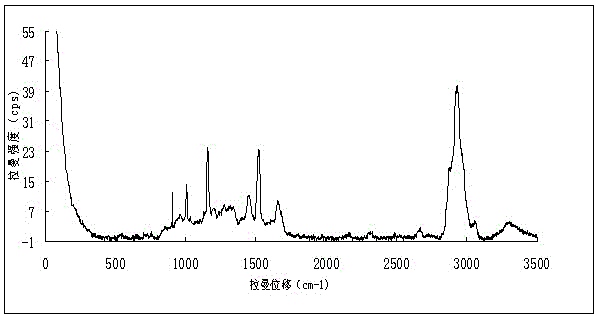

Image

Examples

Embodiment 1

[0016] The present invention includes cleaning, shelling, cryopreservation, freeze-drying of shrimp, Raman spectrum measurement, data processing and other procedures of shrimp, and the specific production process is as follows:

[0017] (1) Shrimp cleaning and shelling: Wash and drain a batch of Penaeus vannamei shrimp with a mass of about 0.5KG, cut off the head, and peel off the shell from the tail;

[0018] (2) Cryopreservation: slice transversely (about 2mm) at the penultimate sarcomere of the tail of Penaeus vannamei, sample each prawn separately, store them at -10°C, and store each group for 2 weeks;

[0019] (3) Freeze-drying of shrimp: Store the sliced shrimp meat for a certain period of time as required, take it out, put it in a -80°C refrigerator for 2-3 hours, and dry it with a vacuum freeze dryer for 24 hours before testing;

[0020] (4) Raman spectrum measurement: NicoletAlmegaXR laser confocal Raman microscope, power 5mW, exposure time 10s, acquisition times 10...

Embodiment 2

[0023] The present invention includes cleaning, shelling, cryopreservation, freeze-drying of shrimp, Raman spectrum measurement, data processing and other procedures of shrimp, and the specific production process is as follows:

[0024] (1) Shrimp cleaning and shelling: Wash and drain a batch of Penaeus vannamei shrimp with a mass of about 0.5KG, cut off the head, and peel off the shell from the tail;

[0025] (2) Cryopreservation: slice transversely (about 2mm) at the penultimate sarcomere of the tail of Penaeus vannamei, sample each prawn separately, store them at -10°C, and store each group for 5 weeks;

[0026] (3) Freeze-drying of shrimp: Store the sliced shrimp meat for a certain period of time as required, take it out, put it in a -80°C refrigerator for 2-3 hours, and dry it with a vacuum freeze dryer for 24 hours before testing;

[0027] (4) Raman spectrum measurement: NicoletAlmegaXR laser confocal Raman microscope, power 8mW, exposure time 10s, acquisition times 10...

Embodiment 3

[0030] The present invention includes cleaning, shelling, cryopreservation, freeze-drying of shrimp, Raman spectrum measurement, data processing and other procedures of shrimp, and the specific production process is as follows:

[0031] (1) Shrimp cleaning and shelling: Wash and drain a batch of Penaeus vannamei shrimp with a mass of about 0.5KG, cut off the head, and peel off the shell from the tail;

[0032] (2) Cryopreservation: slice horizontally (about 2 mm) at the penultimate sarcomere of the tail of Penaeus vannamei, sample each shrimp separately, store them at -10°C, and store each group for 9 weeks;

[0033] (3) Freeze-drying of shrimp: Store the sliced shrimp meat for a certain period of time as required, take it out, put it in a -80°C refrigerator for 2-3 hours, and dry it with a vacuum freeze dryer for 24 hours before testing;

[0034] (4) Raman spectrum measurement: NicoletAlmegaXR laser confocal Raman microscope, power 10mW, exposure time 10s, acquisition times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com