Method for repairing plasma damage in metal interconnection layer process

A technology of metal interconnection layer and ion body, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of no repair of plasma damage, and achieve the effect of saving process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

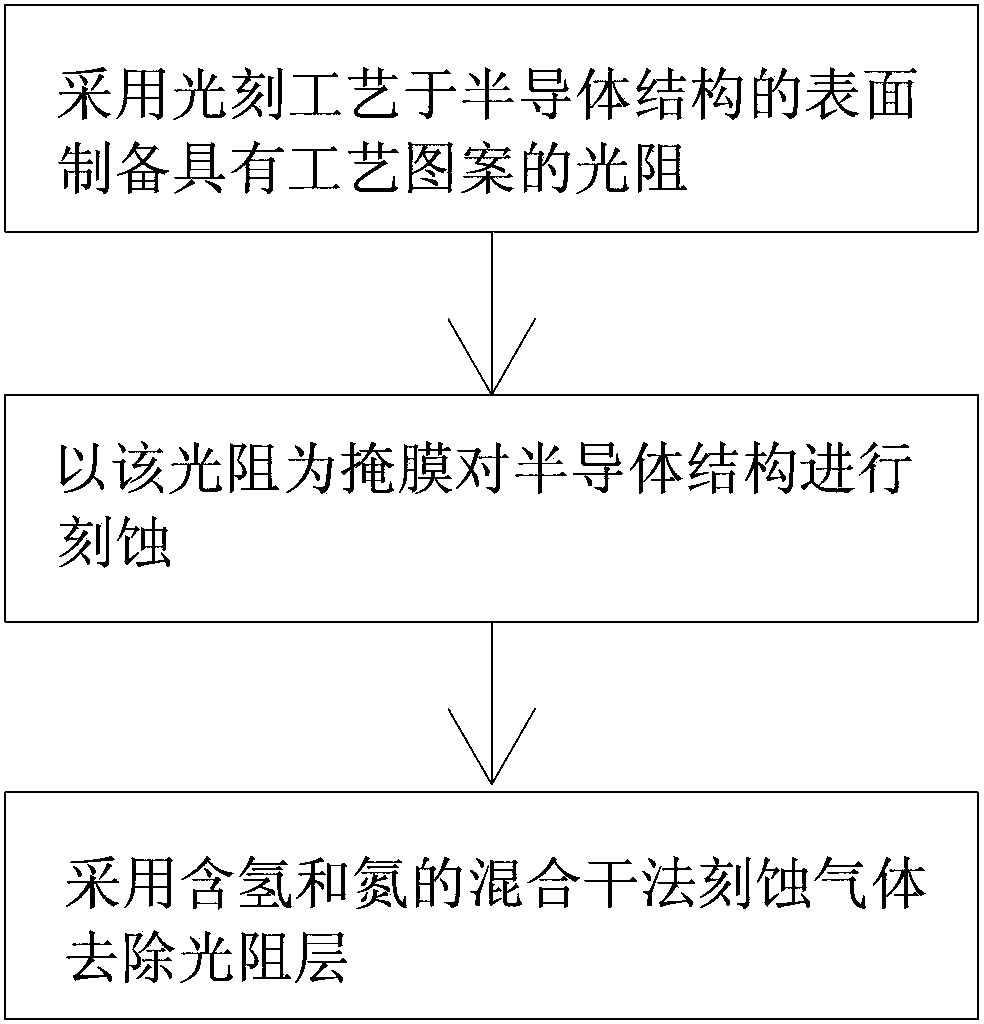

[0025] The invention provides a method for repairing plasma damage in the metal interconnection layer process, which can be used in processes with technology nodes of 90nm, 65 / 55nm, 45 / 40nm, 32 / 28nm and less than or equal to 22nm; the invention can also be used in Logic , Memory, RF, HV, Analog / Power and other technology platforms.

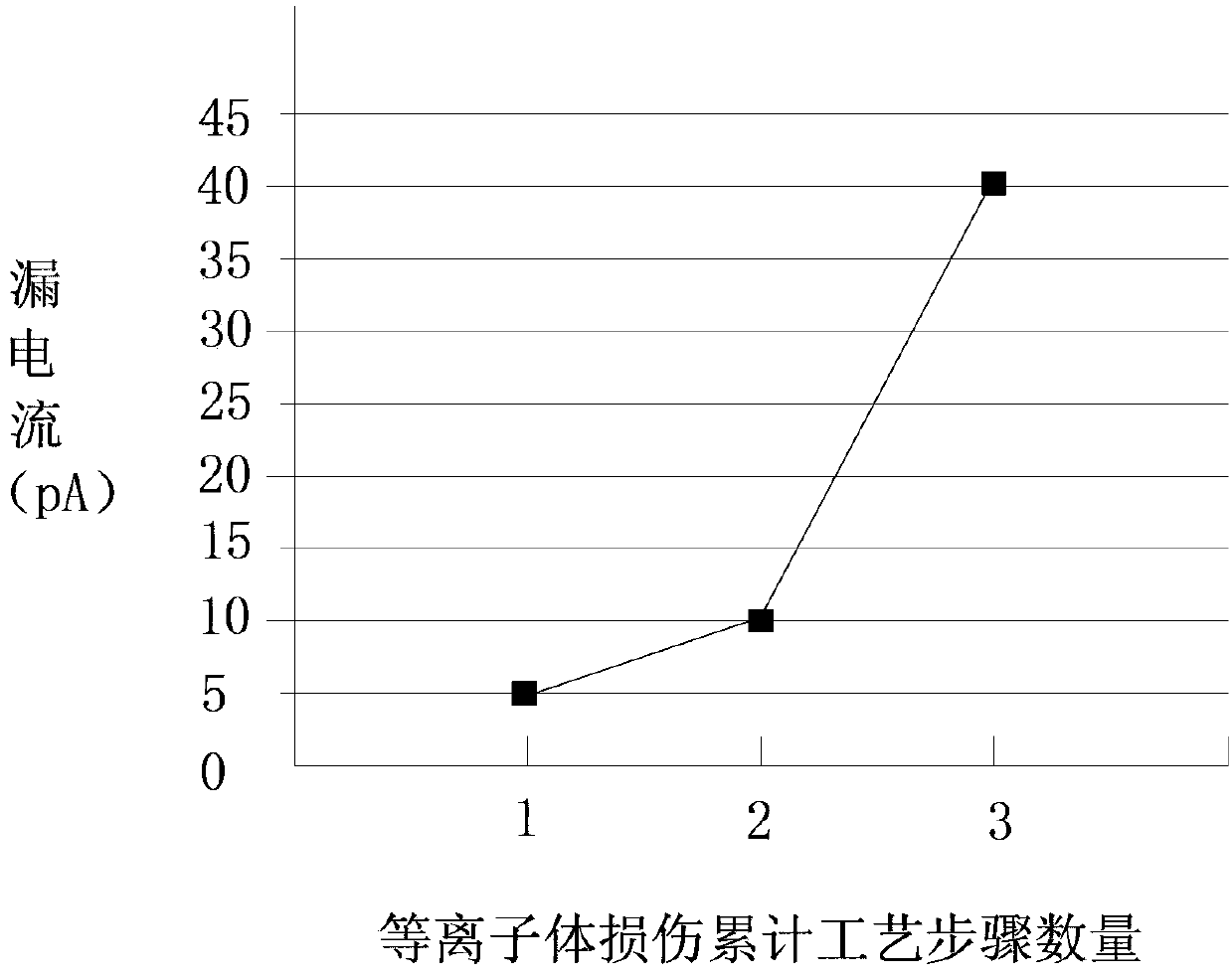

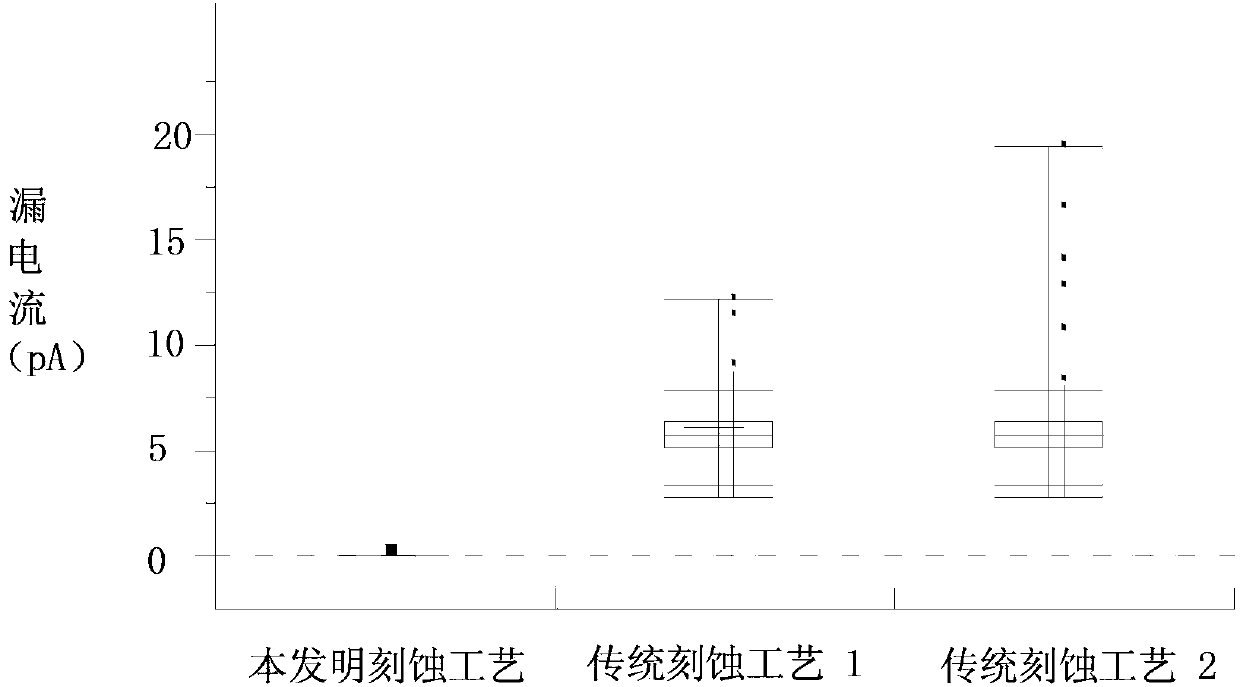

[0026] The main idea of the present invention is to integrate the process step of repairing plasma damage into the etching step of removing the passivation layer of the top layer, not only does not add additional process steps, but also reduces the process of separate hydrogen annealing compared with the traditional process Steps simplify the process steps of the entire metal interconnection layer, and save process time while repairing plasma damage.

[0027] The method of the present invention specifically includes: during the production process of the metal interconnection layer, after the top passivation film is etched and removed, using a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com