Microneedle devices and methods

A technology of microneedles and microneedle arrays, which is applied in the direction of microneedles, needles, and pharmaceutical formulations, and can solve the problems of expensive system manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0171] Preparations containing lidocaine and tetracaine

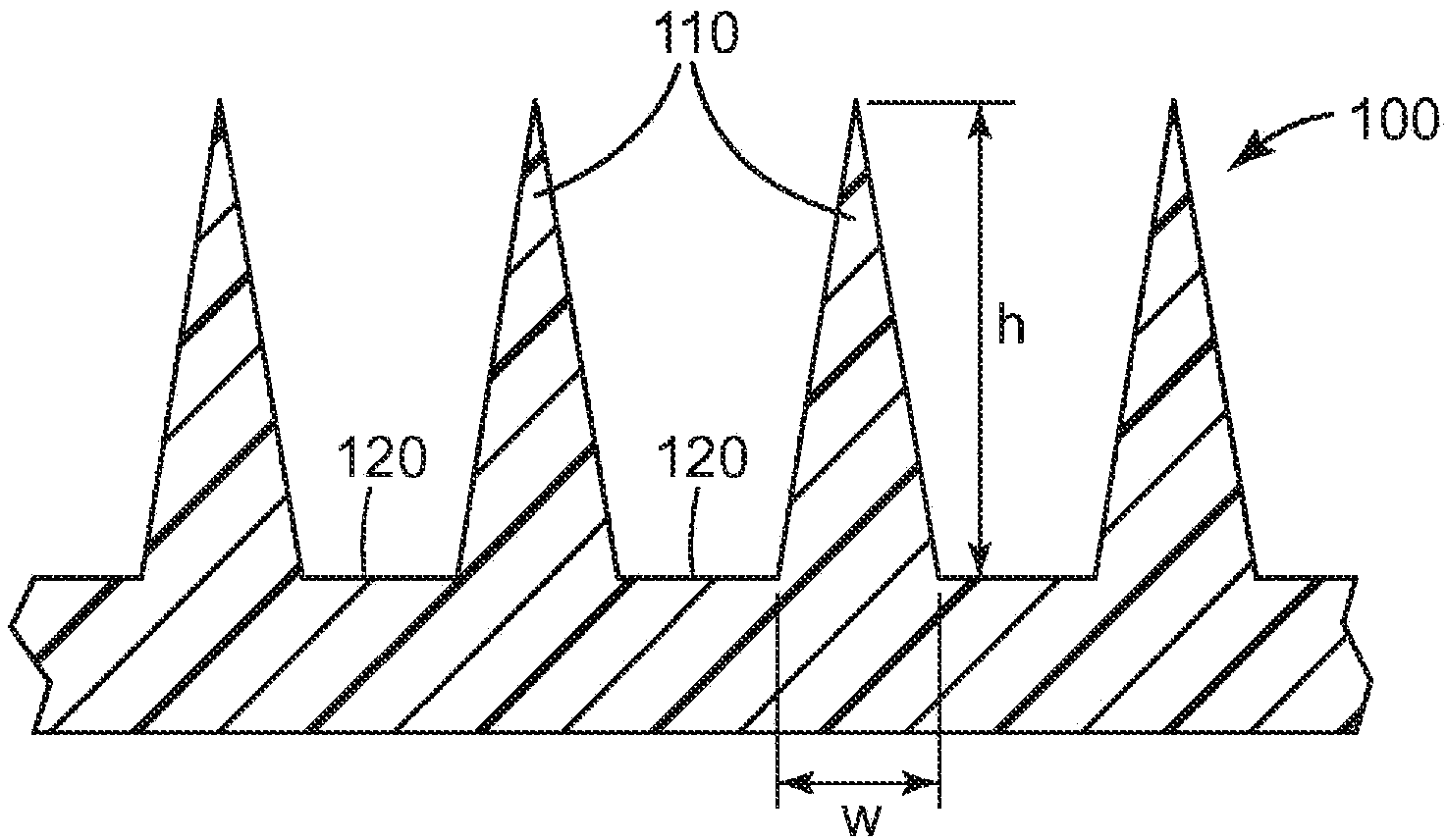

[0172] The microneedle array uses a surface area of about 1.27 cm 2 Class VI medical grade liquid crystal polymer (LCP) ( Injection molded from Ticona Plastics, Auburn Hills, Michigan, USA (3M Company, St. Paul, MN, USA). Each microneedle array is characterized by 316 quadrangular pyramid-shaped microneedles arranged in an octagonal pattern, where the height of the microneedles is nominally 500 microns, the aspect ratio is about 3:1, and the tips between adjacent microneedles reach to The tip distance is nominally 550 microns.

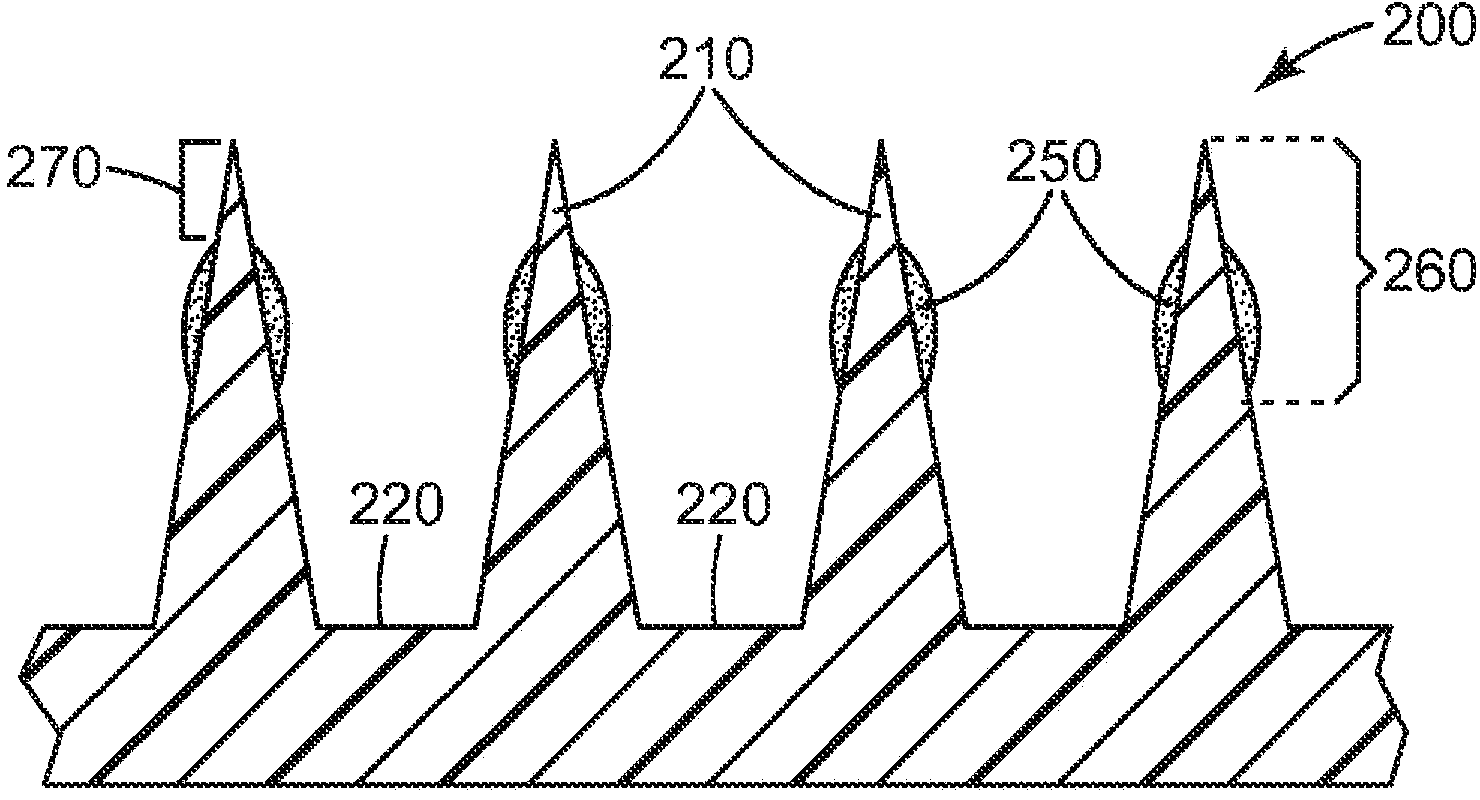

[0173]Using the dip coating method, a mixture of 30% dextran (Pharmacosmos, Holbaek, Denmark), 20% lidocaine hydrochloride (Sigma, St. Louis, Missouri, USA) was used. Company (Sigma, St.Louis, MO)) and tetracaine hydrochloride 10% (Spectrum Chemical & Laboratory Products, New Brunswick, NJ, U.S.A. (Spectrum Chemical & Laboratory Products, New Brunswick, NJ)) & Laboratory Products (Spect...

example 2

[0184] Preparations containing prilocaine and tetracaine

[0185] The microneedle array uses a surface area of about 1.27 cm 2 Class VI medical grade liquid crystal polymer (LCP) ( MT1300 was obtained from Ticona Plastics, Auburn Hills, Michigan, USA and was injection molded (3M Company, St. Paul, MN, USA). Each microneedle array is characterized by 316 quadrangular pyramid-shaped microneedles arranged in an octagonal pattern, where the height of the microneedles is nominally 500 microns, the aspect ratio is about 3:1, and the tips between adjacent microneedles reach to The tip distance is nominally 550 microns.

[0186] Using the dip coating method, a mixture of 30% dextran (Pharmacosmos, Holbaek, Denmark), 12% prilocaine hydrochloride (New Browns, New Jersey, USA) was used. Wake City Spectrum Chemical & Laboratory Products Company (Spectrum Chemical & Laboratory Products, New Brunswick, NJ)) and 8% tetracaine hydrochloride (U.S. New Brunswick, New Jersey Spectrum Che...

example 3

[0197] Preparations containing lidocaine and bupivacaine

[0198] The microneedle array uses a surface area of about 1.27 cm 2 Class VI medical grade liquid crystal polymer (LCP) ( MT1300 was obtained from Ticona Plastics, Auburn Hills, Michigan, USA and was injection molded (3M Company, St. Paul, MN, USA). Each microneedle array is characterized by 316 quadrangular pyramid-shaped microneedles arranged in an octagonal pattern, where the height of the microneedles is nominally 500 microns, the aspect ratio is about 3:1, and the tips between adjacent microneedles reach to The tip distance is nominally 550 microns.

[0199] Using the dip coating method, a mixture of 30% dextran (Pharmacosmos, Holbaek, Denmark), 30% lidocaine hydrochloride (Sigma, St. Louis, Missouri, USA) was used. Company (Sigma, St.Louis, MO)) and 1.7% bupivacaine hydrochloride (MP Biomedicals LLC, Solon, OH) onto the microneedle array. Prior to coating, microneedle arrays were cleaned with 70% isopro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com