Flower fragrance type black tea processing technology

A processing technology and flower-flavored technology, which is applied in the processing technology field of floral-flavored black tea, can solve the problems of losing the value of high-end famous green tea and the waste of Anji white tea, etc., and achieve the effects of low production cost, resource saving, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

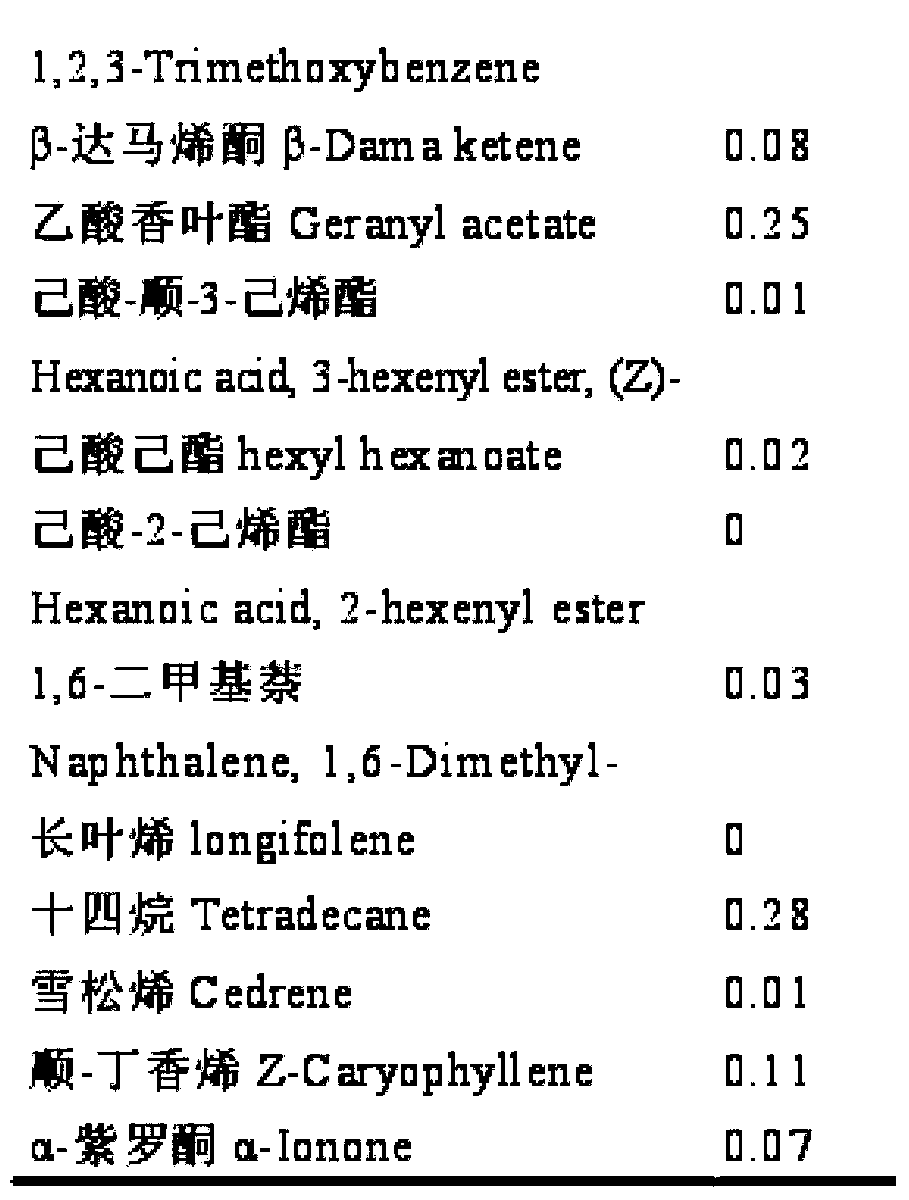

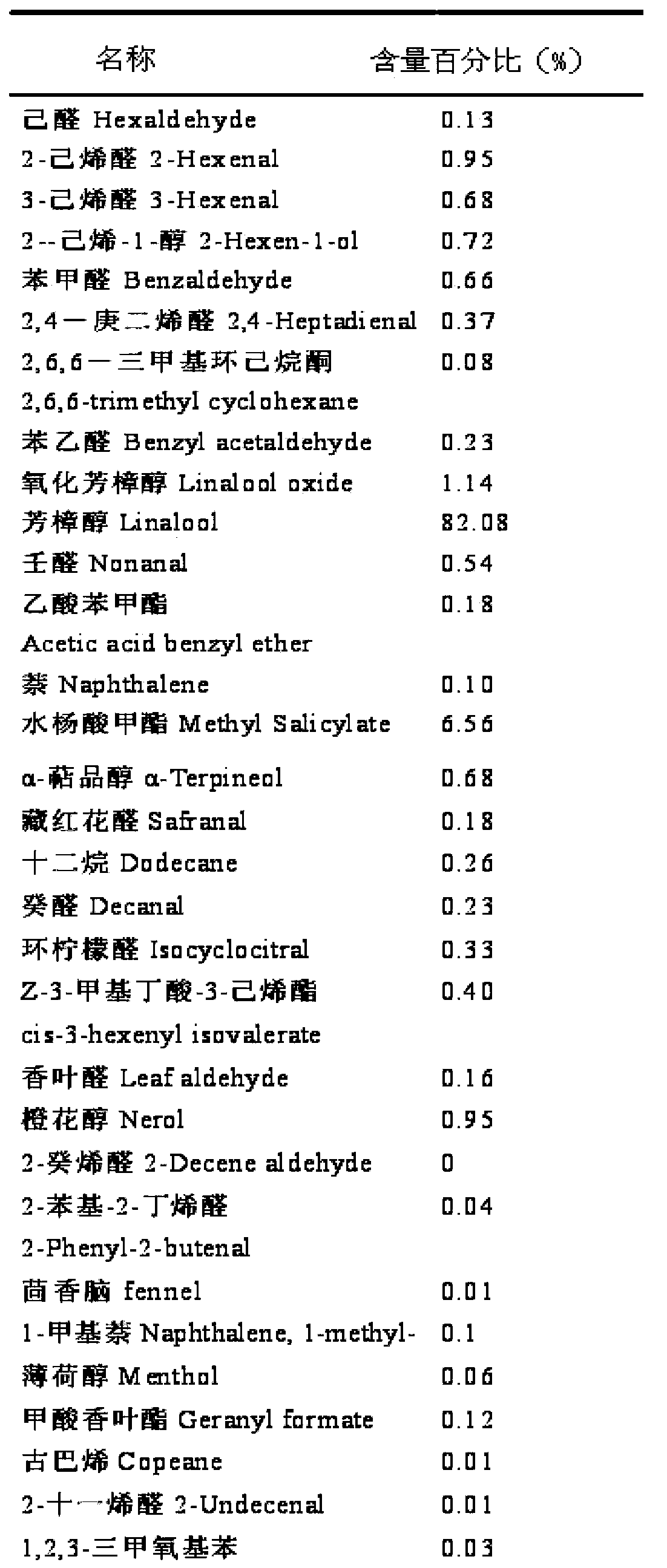

[0019] In this example, headspace solid-phase microextraction (HS-SPME) and gas chromatography-mass spectrometry (GC-MS) techniques are used to analyze and identify the main aroma components of the product of the present invention, in order to further determine the material basis of the tea aroma of the present invention

[0020] 1. Experimental method

[0021] Put 10.0g of tea sample into a 500mL extraction bottle, add 100mL of boiling water, and heat in a water bath at 50°C to allow the aroma substances in the container to reach equilibrium. After 5 minutes, insert the extraction head to absorb for 80 minutes. After the end, use GC-MS for analysis.

[0022] GC conditions: HP-5MS elastic quartz capillary column (30m×0.25mm ID×0.25μm film thickness); the temperature of the injection port is 230°C; desorb at 230°C for 5min after the injection. MS conditions: ionization mode is EI; ion source temperature is 230°C; electron energy is 70eV; scanning range: 50-650amu; carrier gas ...

Embodiment 2

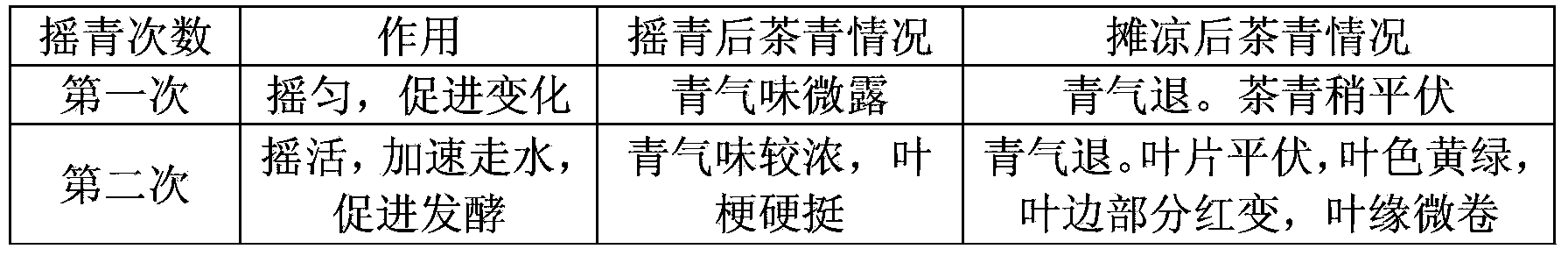

[0033] Pick the fresh leaves of Anji white tea in summer and autumn; the picking standard for fresh leaves is 1 bud and 2 leaves; put the fresh leaves indoors and spread them out to dissipate heat at a temperature of 15°C. Indoor temperature: Thinly spread the treated fresh leaves to dry green, the thickness of the spread leaves is less than or equal to 1cm, the temperature for drying green is 22°C, and the drying time is 20 minutes; after spreading the dried green leaves to 15°C, use a shaker for drying Shake the green twice; shake the green twice: for the first time, shake the cage for 10 revolutions until the green odor of the tea leaves is revealed, then spread the tea leaves and let them stand for 90 minutes until the leaves are soft and the green odor fades; for the second time, shake the cage Rotate for 20 revolutions until the green smell of the tea leaves is revealed again, then spread the tea leaves and let them stand for 90 minutes until the green smell fades and the...

Embodiment 3

[0035] Pick the fresh leaves of Anji white tea in summer and autumn; the picking standard for fresh leaves is 1 bud and 2 leaves; put the fresh leaves indoors and spread them out to dissipate heat at a temperature of 20°C. Indoor temperature: Thinly spread the treated fresh leaves to dry green, the thickness of the spread leaves is less than or equal to 1cm, the temperature for drying green is 25°C, and the drying time is 40 minutes; after spreading the dried green leaves to 20°C, use a shaker to carry out Shake the green twice; shake the green twice: for the first time, shake the cage for 15 revolutions until the green odor of the tea leaves is revealed, then spread the tea and let it stand for 100 minutes until the leaves are soft and the green odor fades; the second time, shake the cage Rotate for 25 turns, until the green odor of the tea leaves is revealed again, then spread the tea leaves and let them stand for 100 minutes until the green smell fades and the fragrance of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com