Production equipment for hemodialysis concentrated solution and production method for hemodialysis concentrated solution

A technology of hemodialysis and production equipment, which is applied in the field of medical devices, can solve the problems of shortening the life of dialysis patients, affecting production efficiency, limiting filtration speed, etc., and achieves the effect of simple structure, small mechanical loss, and improved clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Production volume and raw material volume of liquid A

[0025] Production volume (L)

1000

2000

3000

5000

210.00

420.00

630.00

1050

5.22

10.44

15.66

26.10

9.00

18.00

27.00

45.00

Magnesium chloride (Kg)

3.56

7.12

10.68

17.80

[0026] Step 1: Put the material into the dissolution tank 1, add dialysis water to the amount required by the process to fully dissolve and set the volume to the specified scale, and stir the solution in the dissolution tank evenly;

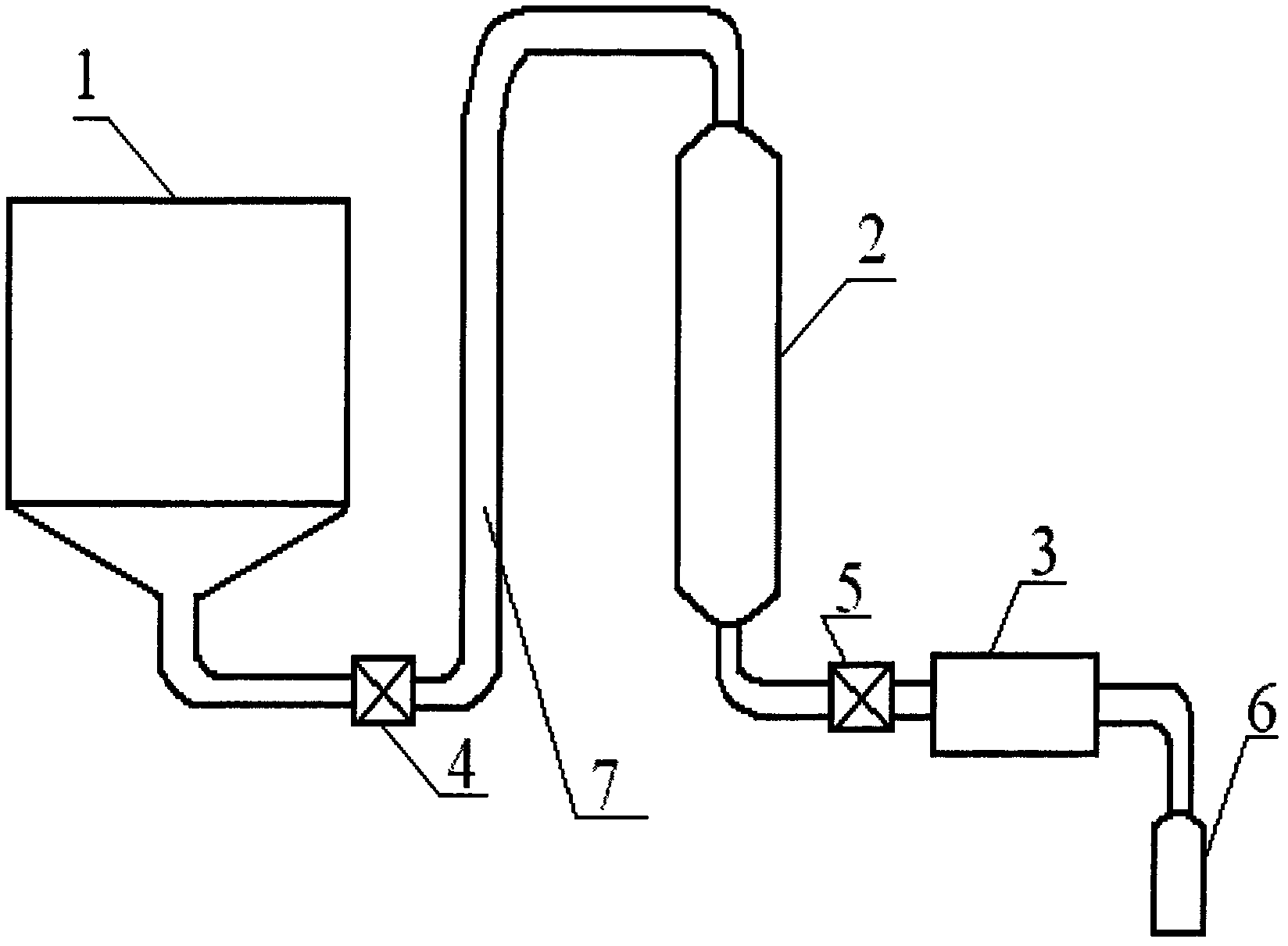

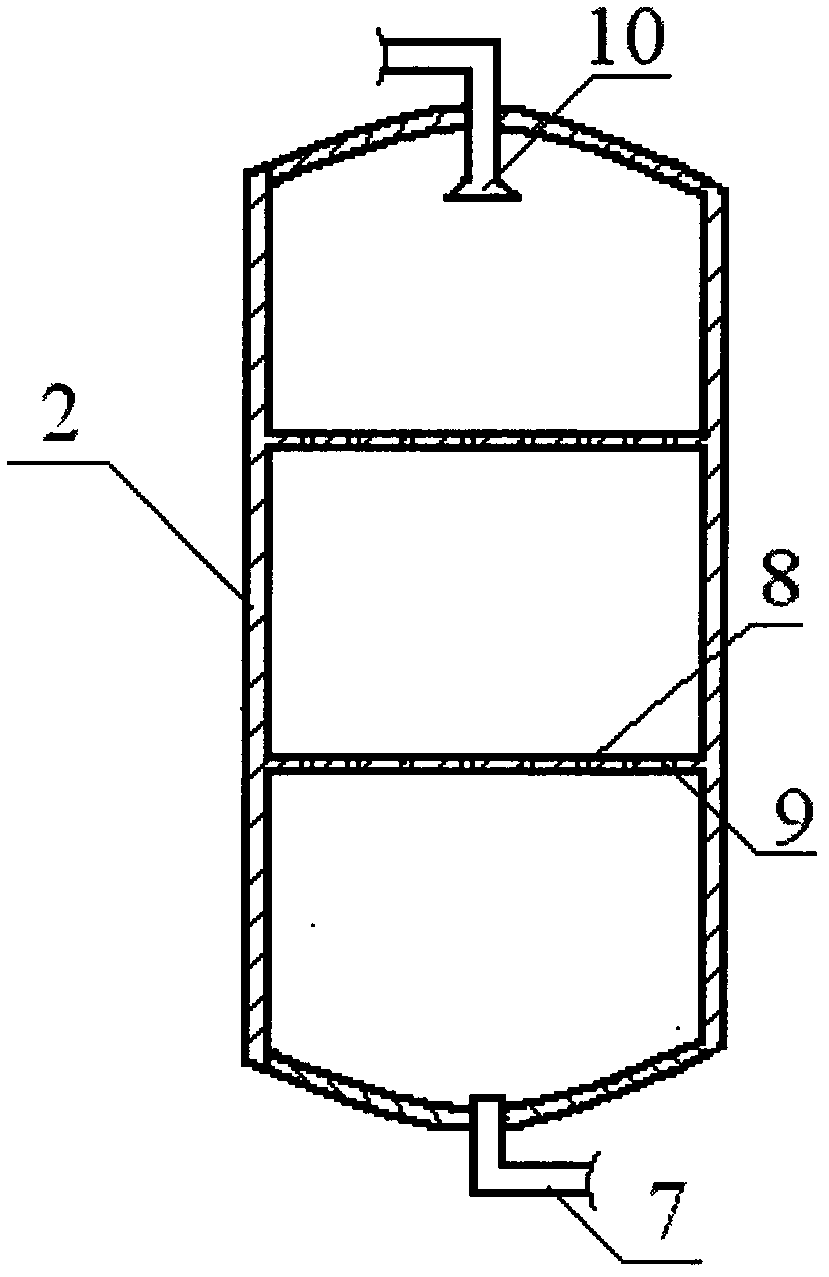

[0027] Step 2: Start the booster pump 1, inject the solution in the dissolution tank 1 into the adsorber 2, and spray the solution down in the absorber 2 through the nozzle 10, and then pass through the horizontal parallel arrangement in the absorber 2 Two partitions 8 divide the inner chamber of the adsorber 2 into three sections....

Embodiment 2

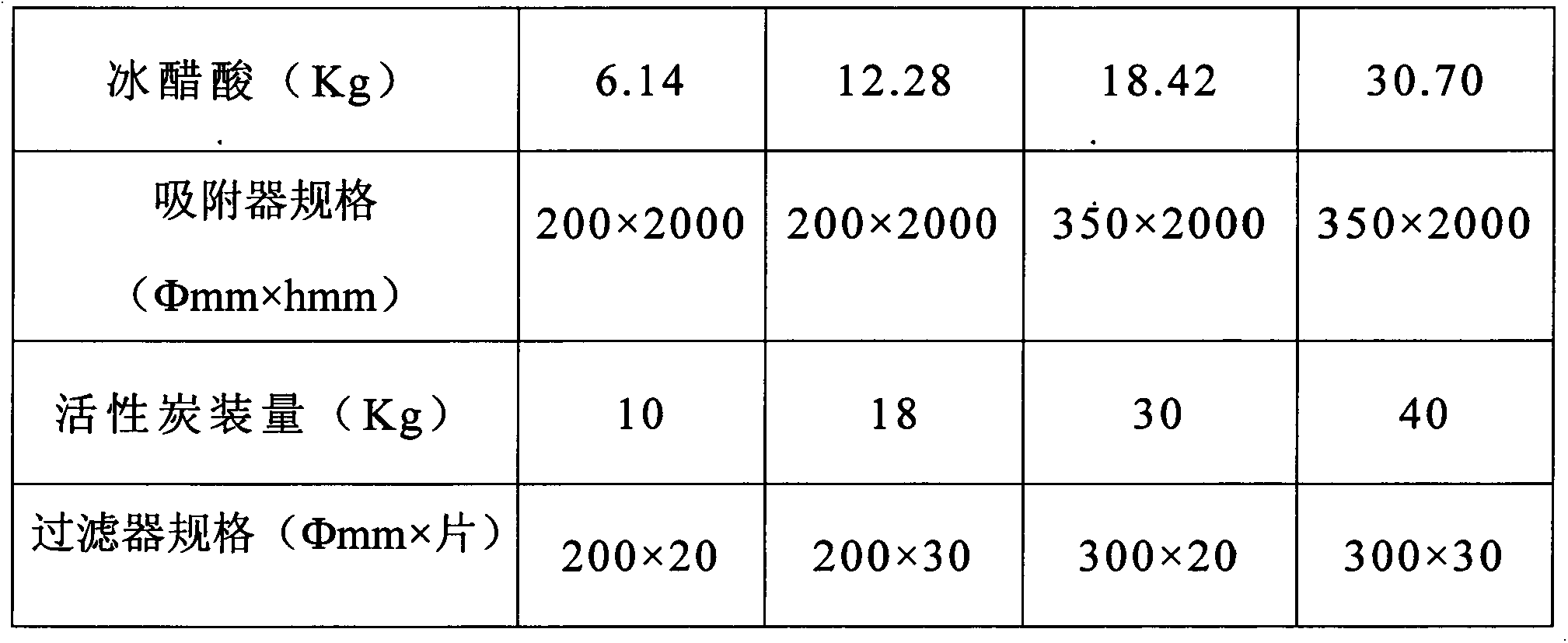

[0035] Production volume of B liquid and specifications of adsorber and plate-and-frame filter

[0036]

[0037] The production steps are the same as in Example 1; another group of adsorbers 2 is used for the filtration of the solution, and at the same time, the adsorbers 2 used in the previous shift are backwashed and activated. The treatment steps are as follows: first use drinking water to backwash for 10 minutes Drain the drinking water, then fill the activation solution made of 3% hydrogen peroxide and soak for 30 minutes, drain the activation solution, then rinse with drinking water for 10 minutes, drain the drinking water, and wash with dialysis water for 5 minutes; wait Use one shift.

[0038]The adsorber 2 and the separator 8 are made of 316L stainless steel, which has strong corrosion resistance and improves the service life of the equipment.

[0039] By adopting the technical scheme of the present invention, the endotoxin content of the prepared hemodialysis con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com