Photocatalytic material Ag/AgMO2 and preparation method thereof

A technology of photocatalytic materials and solid-phase methods, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems that are not enough to guide large-scale industrial applications of photocatalytic technology To achieve the effect of improving the photocatalytic efficiency, expanding the response, and benefiting industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

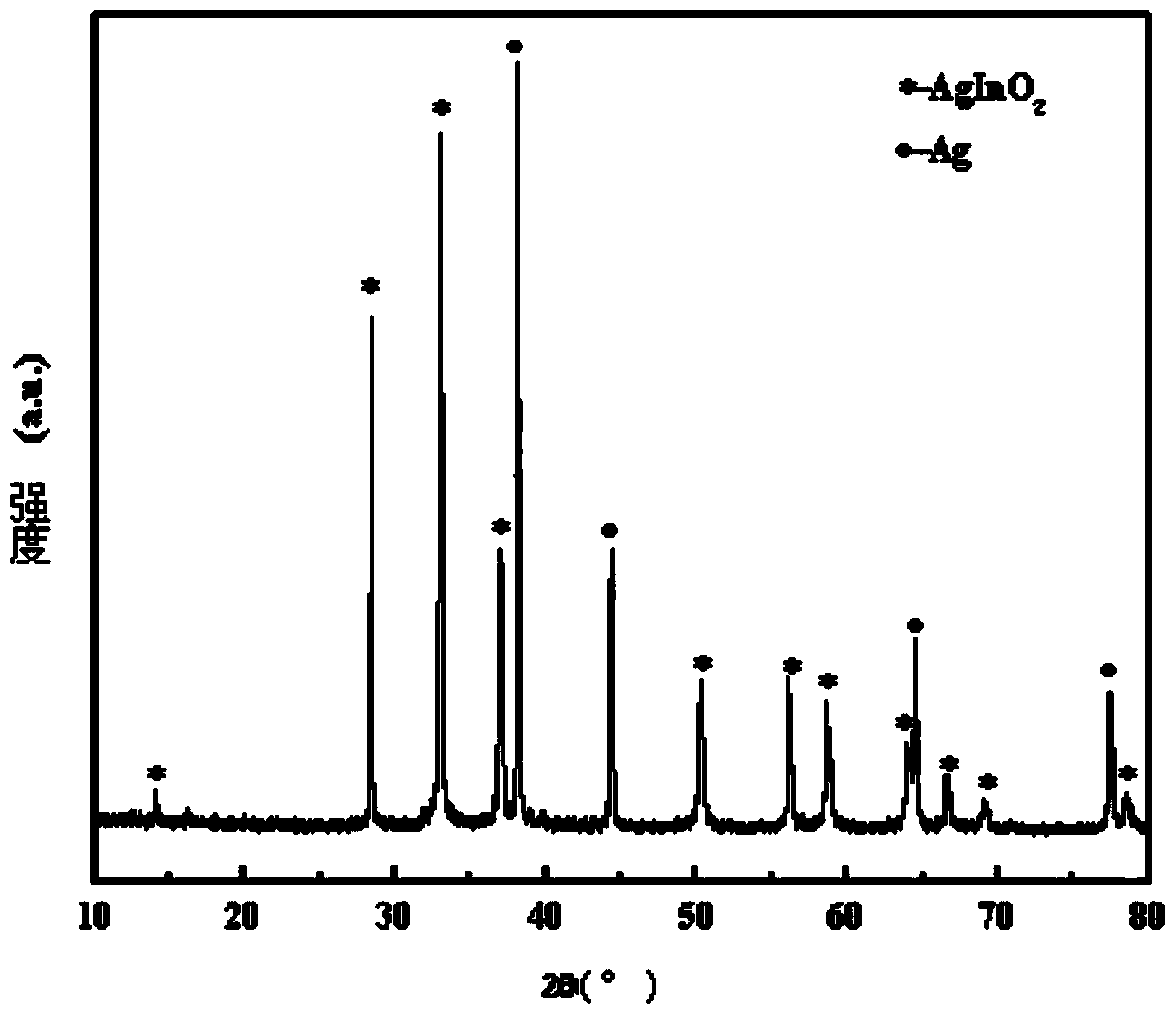

[0042] Ag / AgInO 2 preparation of

[0043] With In(NO) 3 and Na 2 CO 3 As raw material, weigh 0.015mol In(NO) 3 and 0.03mol Na 2 CO 3 Place in an agate mortar, add 0.01mol of NaCl, mix and grind for 10 minutes, transfer the mixture to a corundum crucible, and calcinate at 850°C for 3 hours to obtain the product NaInO 2 . The prepared NaInO 2 with AgNO 3 、KNO 3 According to the molar ratio of 1:1.5:2, mix and grind in an agate mortar for 10 minutes, transfer the mixture to a corundum crucible, calcinate at 270°C for 8h, increase the calcining temperature to 500°C and keep it for 3h, and the obtained product is deionized Wash with water, centrifuge, dry in an oven at 80°C, and grind to obtain Ag / AgInO 2 .

Embodiment 2

[0045] Ag / AgInO 2 preparation of

[0046] to In 2 o 3 and Na 2 O is the raw material, weigh 0.015mol In 2 o 3 and 0.03mol Na 2 O was placed in an agate mortar, 0.02mol of NaCl was added, mixed and ground for 10 minutes, the mixture was transferred to a corundum crucible, and calcined at 850°C for 3 hours to obtain the product NaInO 2 . The prepared NaInO 2 with AgNO 3 、KNO 3 According to the molar ratio of 1:2:1.5, mix and grind in an agate mortar for 10min, transfer the mixture to a corundum crucible, calcinate at 220°C for 10h, increase the calcining temperature to 450°C and keep it for 3h, and the obtained product is deionized Wash with water, centrifuge, dry in an oven at 80°C, and grind to obtain Ag / AgInO 2 .

Embodiment 3

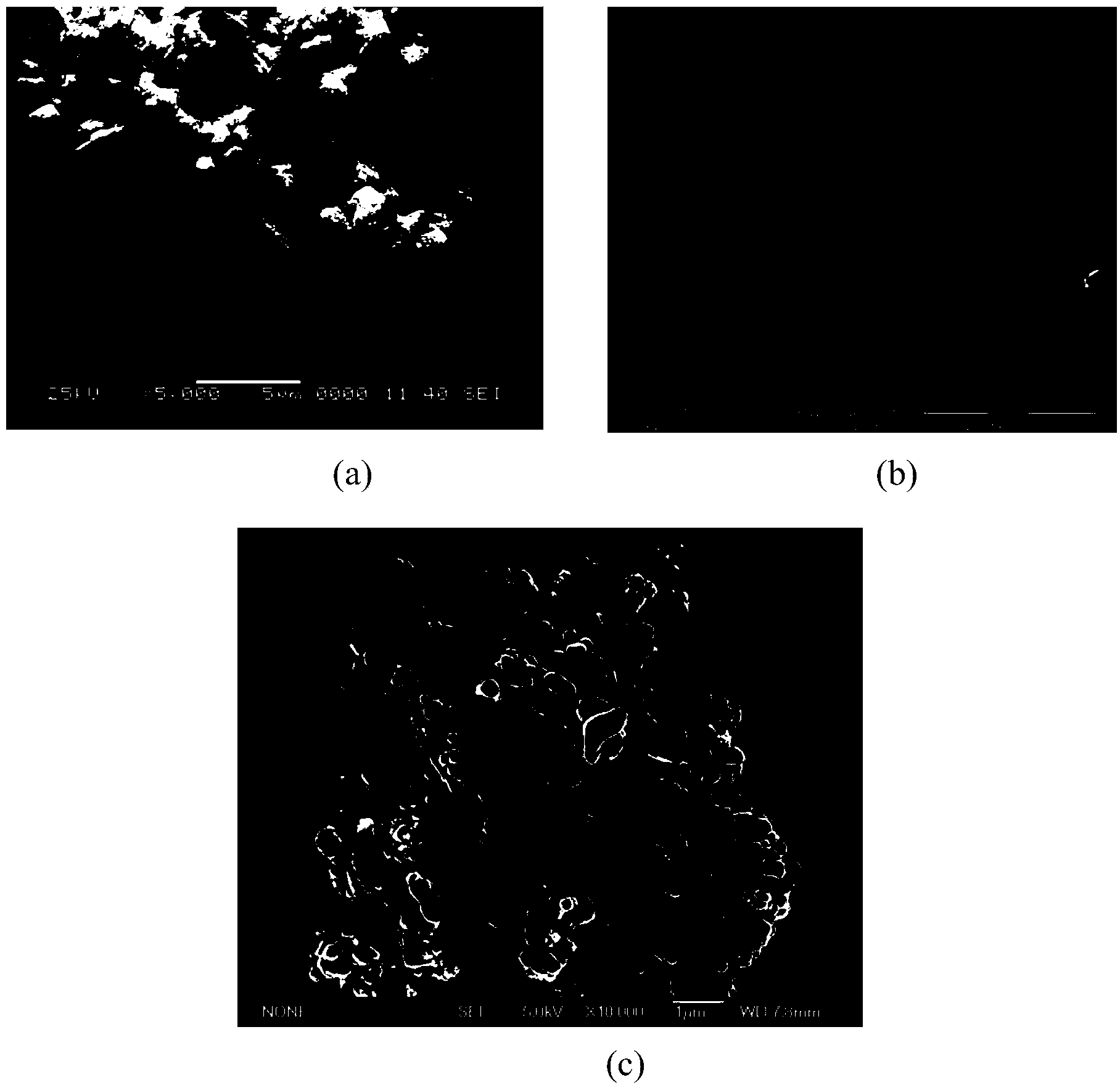

[0048] Ag / AgAlO 2 preparation of

[0049] with Al(NO) 3 and Na 2 CO 3 As raw material, weigh 0.015mol Al(NO) 3 and 0.03mol Na 2 CO 3 Place in an agate mortar, add 0.01mol of NaCl, mix and grind for 10 minutes, transfer the mixture to a corundum crucible, and calcinate at 850°C for 3 hours to obtain the product NaInO 2 . The prepared NaAlO 2 , AgNO 3 、KNO 3 According to the molar ratio of 1:1.5:2, mix and grind in an agate mortar for 10 minutes, transfer the mixture to a corundum crucible, calcinate at 250°C for 10h, increase the calcining temperature to 500°C and keep it for 3h, and the obtained product is deionized Wash with water, centrifuge, dry in an oven at 80°C, and grind to obtain Ag / AgAlO 2 . image 3 (b) is the prepared Ag / AgAlO 2 The scanning electron microscope picture, it can be seen from the figure that the prepared Ag / AgAlO 2 It is polyhedral, with uniform size distribution, and the particle size is 0.2-0.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com