Wet process phosphoric acid production device and method

A wet-process phosphoric acid and production device technology, applied in the field of phosphoric acid, can solve the problems of low phosphorus yield, reduced filtration production capacity, and affected filtration strength, etc., and achieve the effect of improving phosphorus yield and increasing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

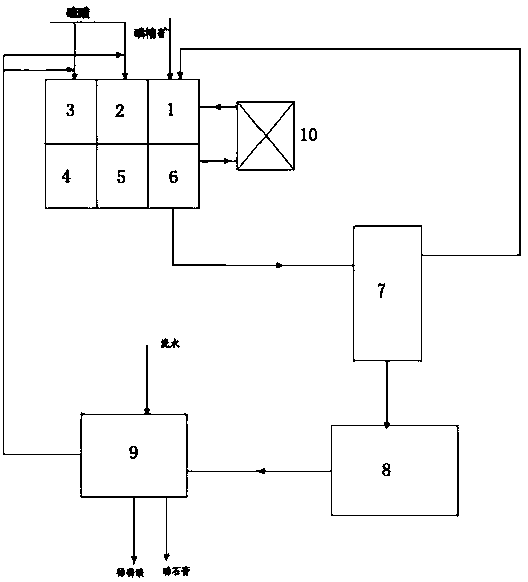

[0024] A kind of wet-process phosphoric acid production device, this device comprises acidolysis reaction tank, cyclone 7, large crystal collection tank 8 and solid-liquid separation device 9; 1-6 chambers, the reaction tank 6 and chamber 6 are connected to the cyclone 7; the outlet of the lower section of the cyclone 7 is connected to the large crystal collection tank 8, and the outlet of the upper section of the cyclone 7 is provided with a pipeline connected to the reaction Groove 1 chamber 1; The outlet of the large crystal collection tank 8 is connected to the solid-liquid separation device 9; the washing water removal pipeline of the solid-liquid separation device 9 is connected to the reaction tank 2 chamber 2 and the reaction tank 3 chamber of the acidolysis reaction tank 3.

[0025] The acidolysis reaction tank is provided with a flash cooling system 10 to cool the reaction slurry and reduce the reaction temperature.

[0026] The flow direction of the reaction chambe...

Embodiment 2

[0031] A kind of phosphoric acid production method, described method adopts the device of embodiment 1, and concrete processing step is as follows:

[0032] (1) React phosphorus concentrate and sulfuric acid in the acidolysis reaction tank to generate phosphoric acid slurry;

[0033] (2) The phosphoric acid slurry from the acidolysis reaction tank is sent to the cyclone 7, the material from the lower section of the cyclone 7 enters the large crystal collection tank 8, and the slurry from the upper section of the cyclone 7 returns to the acid hydrolysis tank, its fine crystals continue to grow after circulating in the acid hydrolysis tank;

[0034] (3) Pump the slurry in the large crystal collection tank 8 into the solid-liquid separation device 9 for solid-liquid separation, and the separated liquid phase is dilute phosphoric acid, which enters the dilute phosphoric acid pipeline;

[0035] (4) The separated solid-phase phosphogypsum is washed with water, and the washing l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com