Separation method and separation device of synthesis gas ethylene glycol product

A separation method and ethylene glycol technology are applied in the separation/purification of hydroxyl compounds, the separation/purification of carboxylic acid esters, organic chemistry, etc., which can solve the problems of high energy consumption and complex process, and achieve the purpose of reducing energy consumption and saving energy. The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

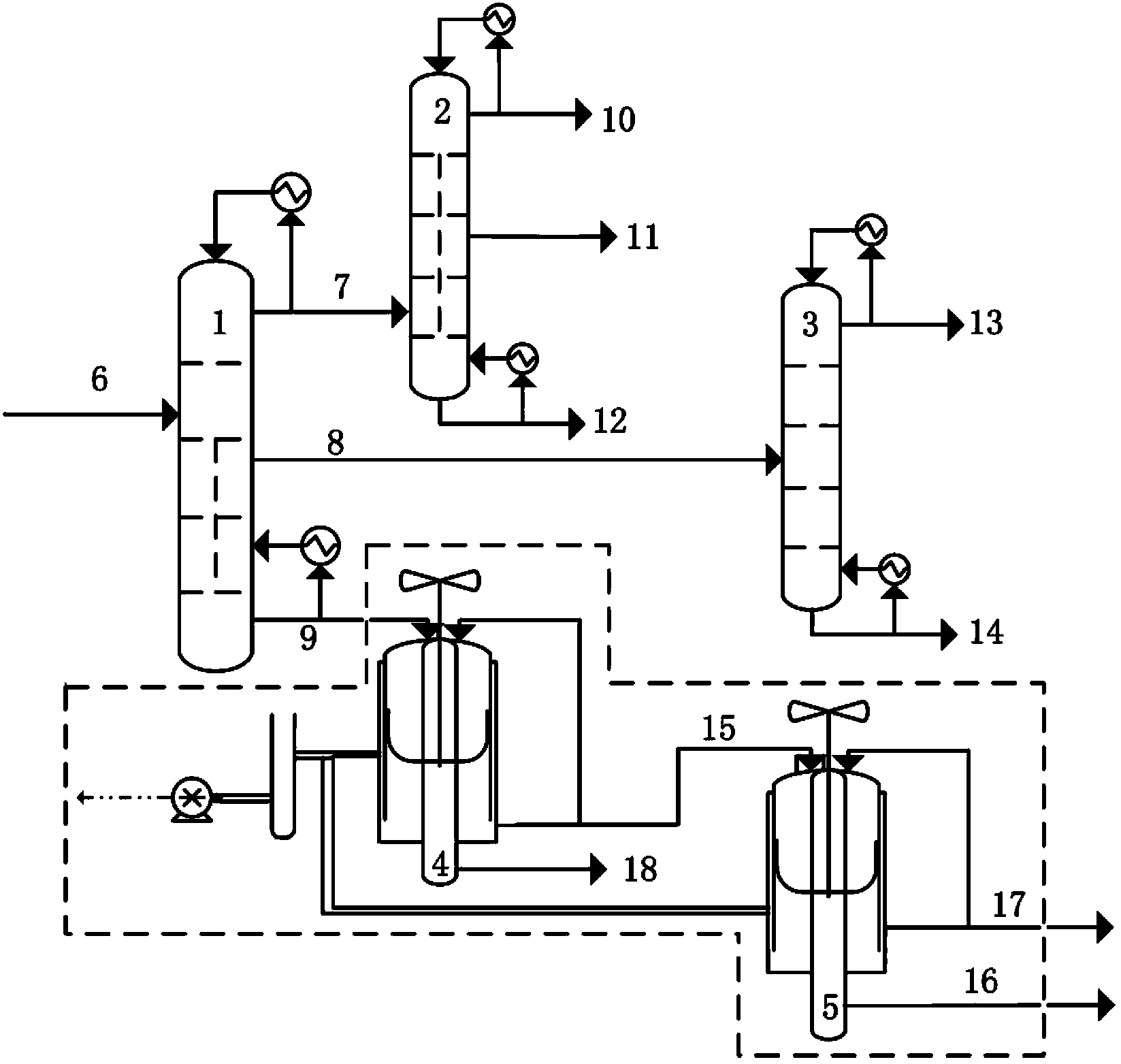

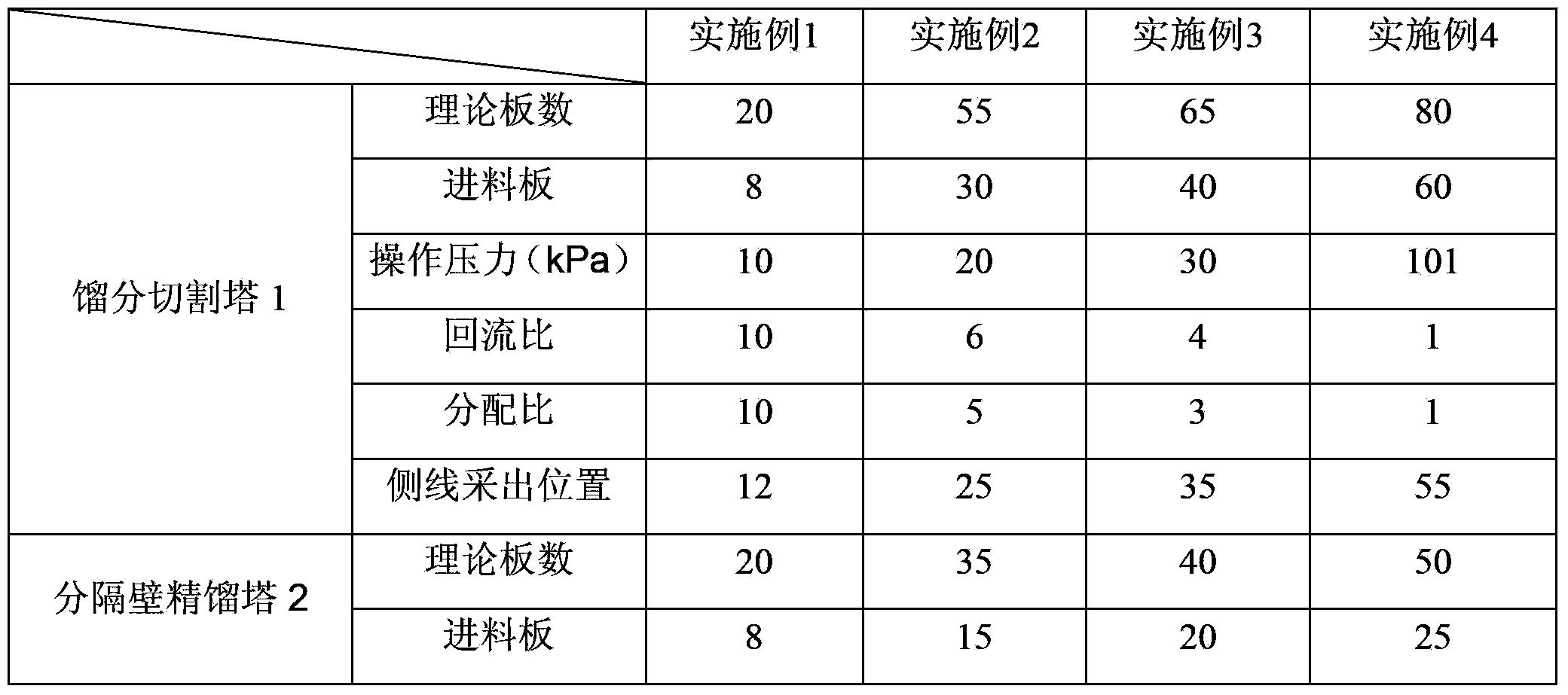

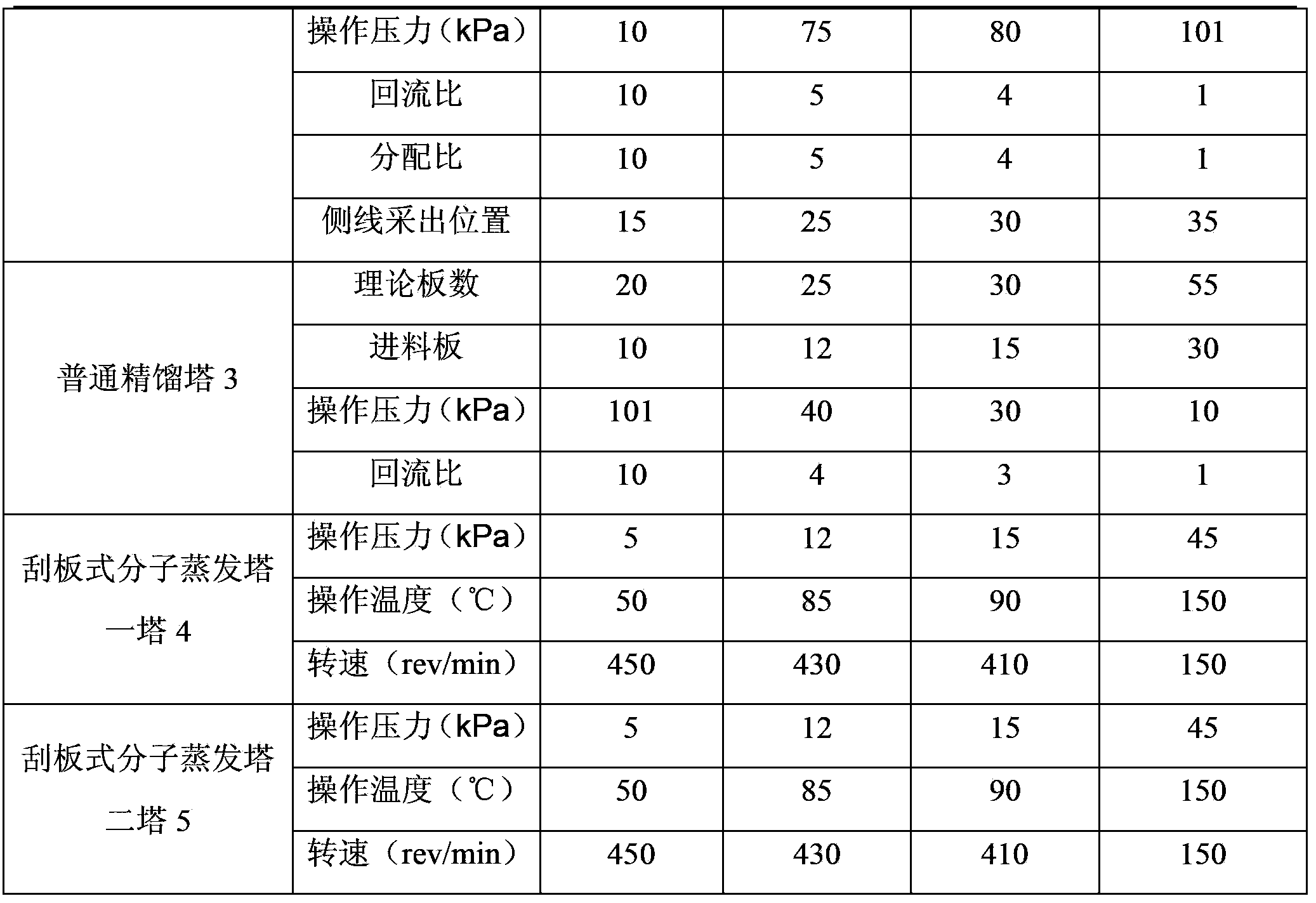

[0037] according to figure 1 In the process shown, the product of synthesis gas to ethylene glycol is used as raw material, and enters the main body of each equipment in turn according to the specific implementation steps. The equipment parameters are shown in Table 1, and the logistics data of each tower after the operation is stable are shown in Table 2.

Embodiment 2

[0039] according to figure 1 In the process shown, the product of synthesis gas to ethylene glycol is used as raw material, and enters the main body of each equipment in turn according to the specific implementation steps. The equipment parameters are shown in Table 1, and the logistics data of each tower after the operation is stable are shown in Table 3.

Embodiment 3

[0041] according to figure 1 In the process shown, the product of synthesis gas to ethylene glycol is used as raw material, and enters the main body of each equipment in turn according to the specific implementation steps. The equipment parameters are shown in Table 1, and the logistics data of each tower after the operation is stable are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com