Preparation and nitrile rubber hydrogenation application of tannic acid rhodium coordination catalyst

A technology of coordination catalyst and tannic acid, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, organic chemistry, etc., can solve the constraints of development, poor selectivity of ruthenium-based catalysts, High temperature and hydrogen pressure and other problems, to achieve the effect of convenient weighing, good air stability and high hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

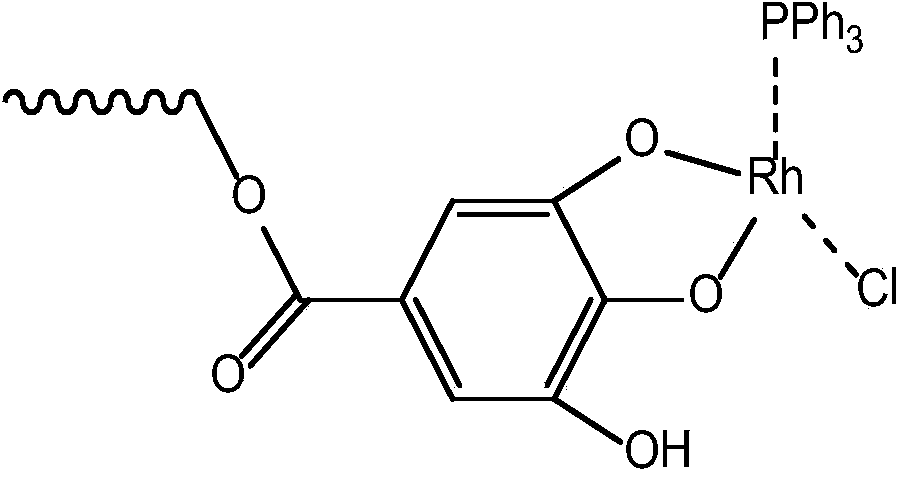

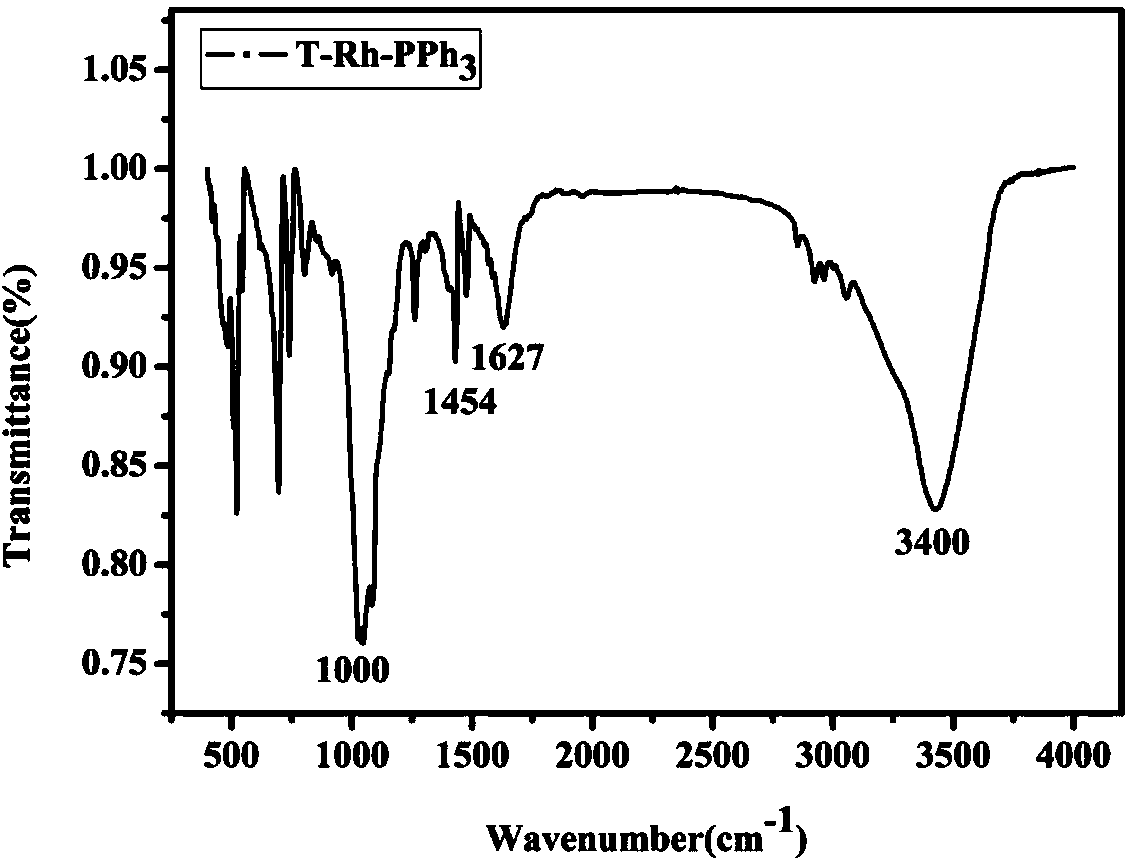

[0022] T-PPh 3 -RhCl 3 The preparation process of the catalyst is as follows:

[0023] First mix rhodium chloride and tannic acid according to the mass ratio of 1:3, add deionized water, dissolve rhodium chloride and tannic acid, after dissolving, adjust the pH value of the solution to 2, at 40 ℃ Stir and react for 8 hours, then add the dissolved triphenylphosphine ethanol solution, wherein the mass ratio of triphenylphosphine to rhodium chloride is 4:1, under the protection of nitrogen, exhaust nitrogen 2 to 3 times, heat up Stir the reaction at 100°C for 2h, suction filter in a glove box, wash and dry to obtain T-PPh 3 -RhCl 3 catalyst.

[0024] T-PPh 3 -RhCl 3 Catalyst carries out solution method catalytic hydrogenation general steps to nitrile rubber as follows:

[0025] The nitrile rubber is formulated into different concentrations of glue, added to the high-pressure hydrogenation reactor, and then the catalyst and the phosphine ligand are added. Under the conditio...

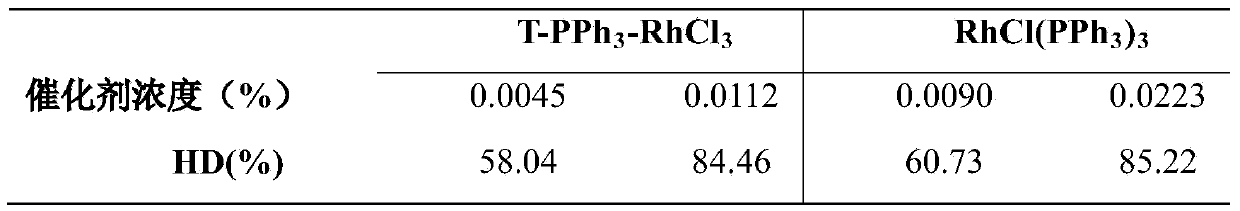

example 1

[0027] According to the above-mentioned general steps of hydrogenation, measure 80ml of the prepared nitrile rubber chlorobenzene glue, the concentration of the glue is 6%, add it to a 0.1L autoclave, and add T-PPh 3 -RhCl 3 Catalyst (here the concentration of catalyst is converted into the mass percentage of rhodium relative to the dry rubber), under the condition of reaction temperature of 100°C and hydrogen pressure of 2.5MPa, react for 6h, cool, condense with ethanol to obtain the hydrogenated product HNBR, dry in vacuum Dry in the oven and measure the degree of hydrogenation. The results are shown in Table 1

example 2

[0033] The prepared dried T-Rh-PPh 3 The catalyst was taken out from the glove box and placed in the air at intervals of 2d, 4d, 8d and 20d. According to the above-mentioned general steps of hydrogenation, measure 80ml of the prepared nitrile rubber chlorobenzene glue with a graduated cylinder, the concentration of the glue is 6%, and add it to a 0.1L autoclave, T-PPh 3 -RhCl 3 The concentration of the catalyst is 0.208%, and the amount of triphenylphosphine is 4 times the amount of the catalyst. Under the conditions of the reaction temperature of 120 ° C and the hydrogen pressure of 2.5 MPa, the reaction is carried out for 6 hours, cooled, and condensed with ethanol to obtain the product HNBR, which is dried in vacuum Dry in the oven, and measure the degree of hydrogenation of the product HNBR. The results are shown in Table 2

[0034] Table 2. T-PPh 3 -RhCl 3 Catalyst Air Stability

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com