High-grade water-based paint containing filling material titanium dioxide

A technology of water-based paint and titanium dioxide, applied in the direction of starch paint, coating, etc., can solve the problems of restricting the rapid development of enterprises, raising costs, and affecting competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

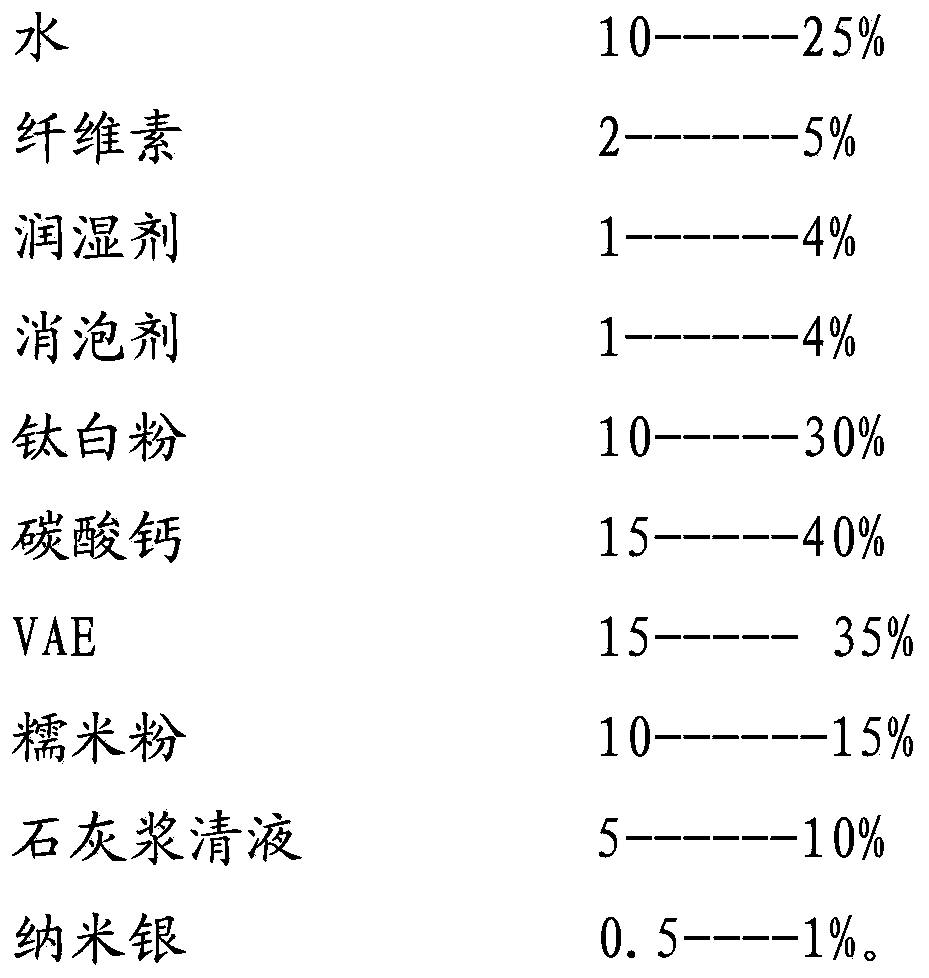

Method used

Image

Examples

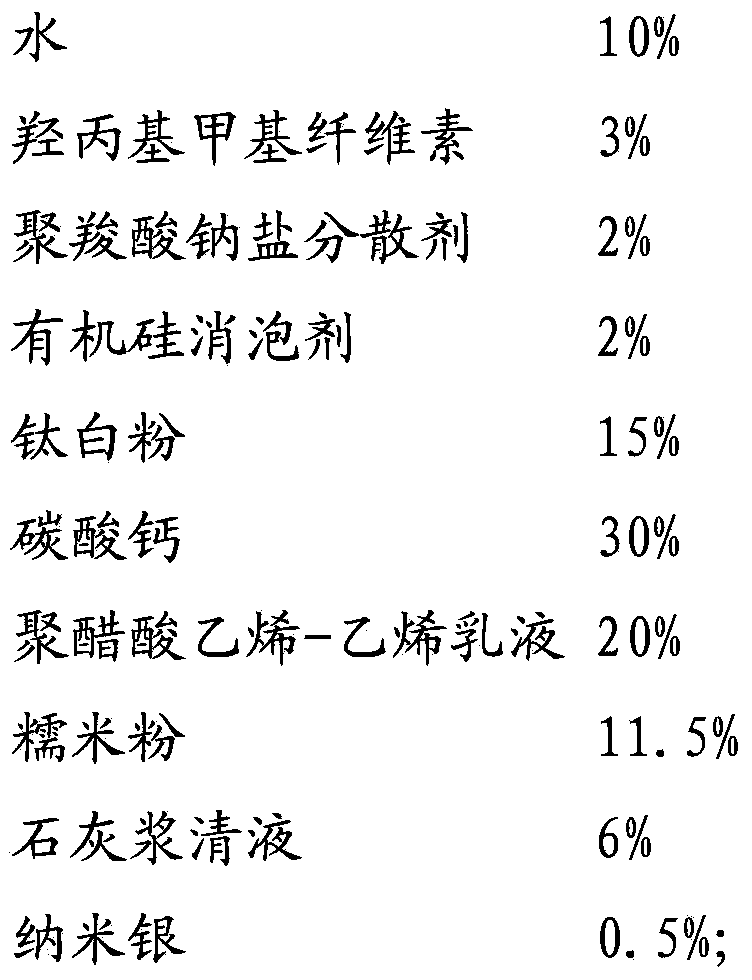

Embodiment 1

[0030] First, add quicklime into water and stir for 30 minutes. After clarification, take the upper solution as lime slurry clear liquid for later use.

[0031] According to the following formula (according to the number of parts by mass), the following steps:

[0032]

[0033] ① Add hydroxypropyl methylcellulose to water and stir for 30 minutes;

[0034] ② Add polycarboxylate sodium salt dispersant and silicone defoamer in sequence and stir for 30 minutes;

[0035] ③Add titanium dioxide and superfine calcium carbonate to disperse strongly for 30 minutes;

[0036] ④Add polyvinyl acetate-ethylene emulsion and glutinous rice flour and stir for 20 minutes;

[0037] ⑤ Add lime slurry and stir for 20 minutes;

[0038] ⑥Add nano-silver and stir for 20 minutes;

[0039] 7. become the finished coating of the present invention after filtering, pack.

[0040] The hydroxypropyl methylcellulose, referred to as UPMC, is produced in the United States, and the manufacturer is Ashland...

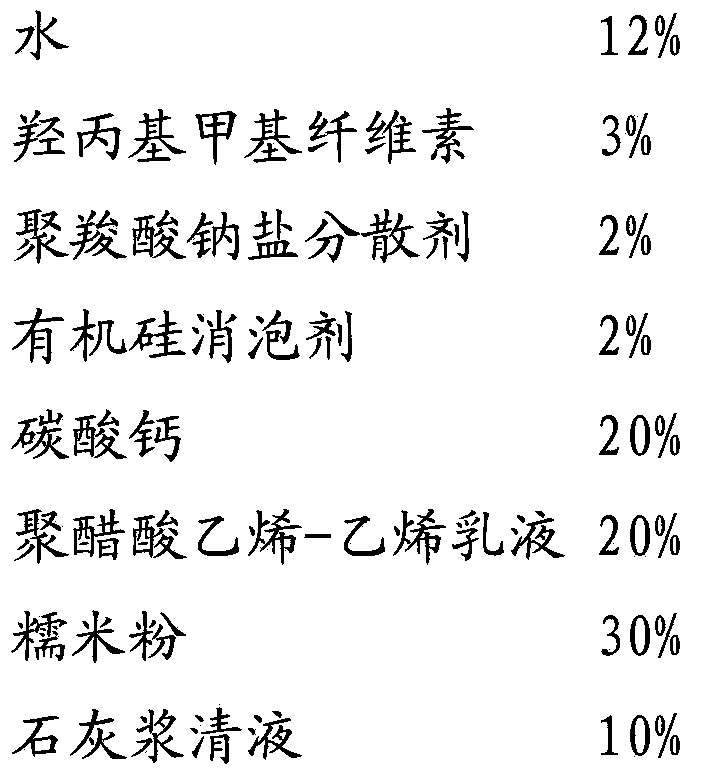

Embodiment 2

[0047] First, add quicklime into water and stir for 30 minutes. After clarification, take the upper solution as lime slurry clear liquid for later use.

[0048] According to the following formula (according to the number of parts by mass), the following steps:

[0049]

[0050]

[0051] Adopt this formula, produce 10 batches of coatings according to the production method of embodiment one, its main technical index is all in the scope of following table:

[0052] pH value

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap