Lossless frustule conveying system for sealed type photobioreactor

A technology of photobioreactor and delivery system, which is applied in the field of closed photobioreactor algae cell non-destructive circulation delivery system, which can solve the problems of large power consumption and adverse effects of algae photosynthesis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

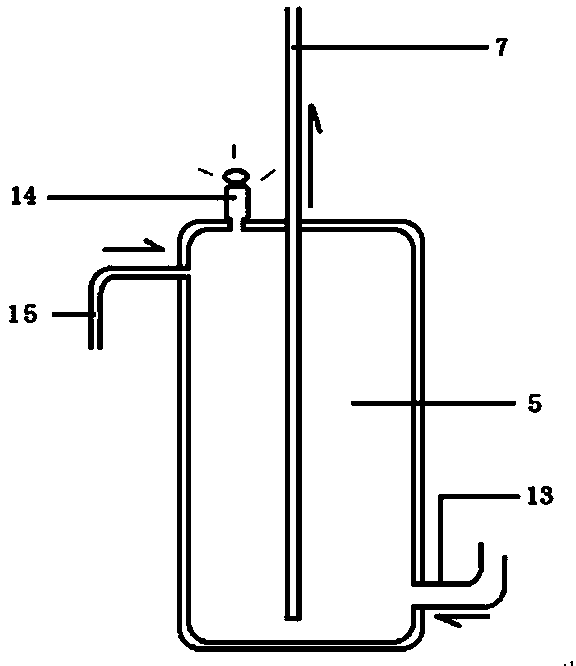

[0026] According to the structure described above, a non-destructive delivery system for algae cells is constructed.

[0027] Algae species: Spirulina platensis.

[0028] Light intensity: The light intensity range is 2000-10000Lx under outdoor conditions.

[0029] Cultivation time: 6 days, algal filaments do not break and die, and the biomass of Spirulina is 1.7-2.5g (dry weight) / L when harvested, which is 40-40% higher than that of pipeline photobioreactors using pump circulation. 70%.

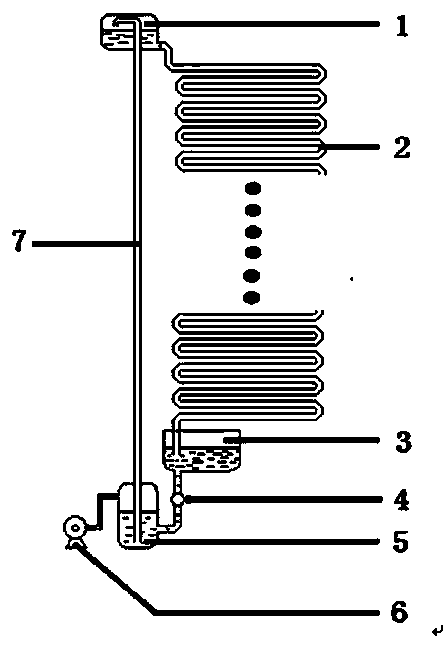

[0030] Pipeline photobioreactor: S-shaped transparent glass reactor with a vertical height of 9.6 meters.

[0031] The diameter of the infusion tube 2 is four times that of the infusion tube 1 .

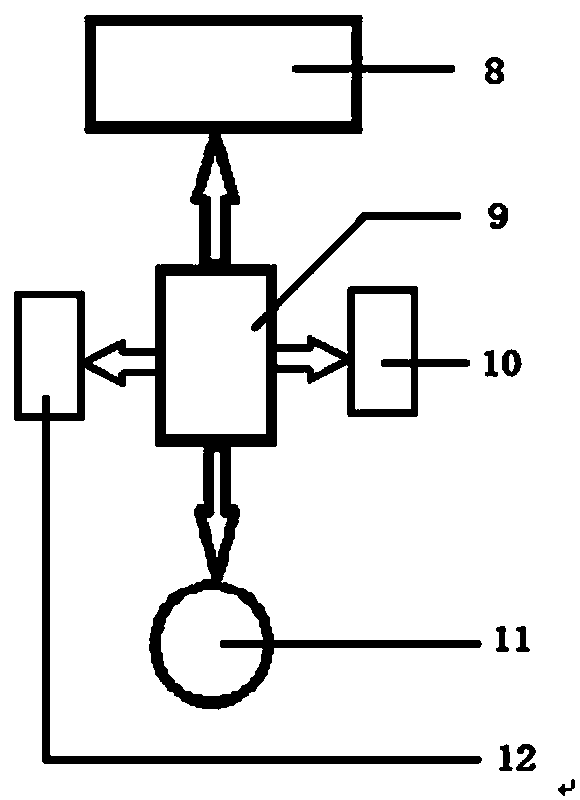

[0032]When in use: start the water level sensor (8), when it is detected that the water level of the algae liquid in the high level liquid storage tank (1) is lower than the low water level control point, the water level sensor (8) will feed back the signal to the single chip microcomputer (9) th...

Embodiment 2

[0035] The system structure and working principle are the same as those in Embodiment 1.

[0036] When adopting the present invention to cultivate Haematococcus pluvialis, under outdoor conditions, the light intensity range is 2000-10000Lx, and after 10 days of cultivation, the algae cells do not appear to be lost and dead due to mechanical shearing, and the biomass at harvest is 1.3-2.0g (dry weight) / L, which is 63% higher than the biomass of pipeline photobioreactors using pump circulation.

[0037] What is described above is only the preferred embodiment of the patent of the present invention. The device of the invention is easy to manufacture, has low investment cost, and is convenient for carrying out research work on large-scale culture of algae cells and optimization of culture conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com