Micro-aerobic straw pretreatment and hydrogen and marsh gas combined fermentation system and method

A technology of combined fermentation and pretreatment, applied in the field of hydrogen biogas fermentation system, can solve the problems of difficult utilization of straw and uneven illumination, and achieve the effects of compact structure, convenient operation and avoiding uneven illumination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

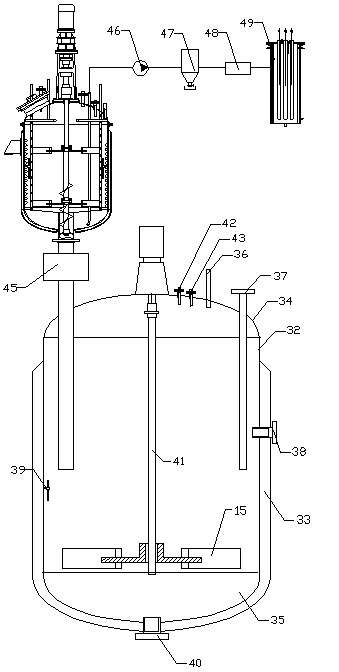

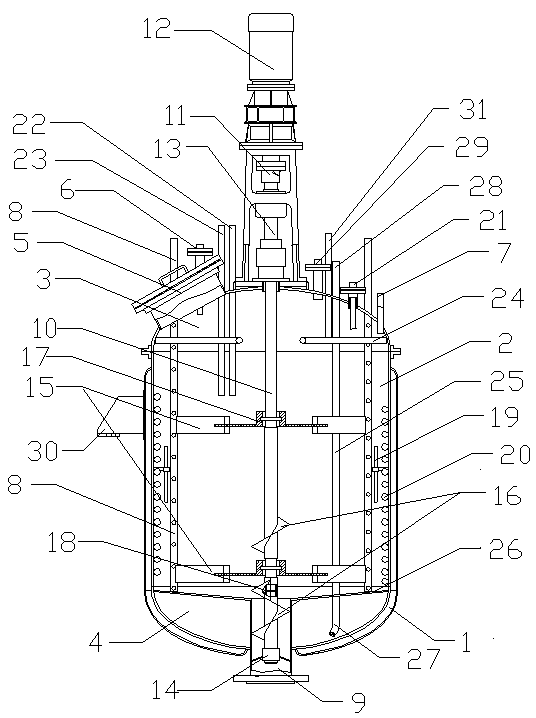

[0022] Such as figure 1 As shown, the present invention includes a photosynthetic hydrogen production reactor 49 and a biogas fermentation tank respectively connected to the pretreatment reaction tank. The hydrogen reactor 49 produces hydrogen, and the solid material produced in the pretreatment reaction tank enters the biogas fermentation tank body 32 for fermentation.

[0023]The pretreatment reaction tank includes a pretreatment reaction tank body 2 arranged in the pretreatment reaction tank jacket 1, and the upper and lower ends of the pretreatment reaction tank body 2 are respectively provided with a pretreatment reaction tank upper head 3 and a pretreatment reaction tank The lower head 4, the upper head 3 of the pretreatment reaction tank are provided with a pretreatment reaction tank material inlet 5, a pretreatment reaction tank material sampling port 6 and a pretreatment reaction tank gas outlet 7, and the pretreatment reaction tank body 2 It is equipped with oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com