A pre-purification method and product before melting and casting of high-temperature electrolytic molten aluminum

A technology of electrolytic aluminum liquid and pre-purification, which is applied in the field of purification before using electrolytic aluminum liquid for melting and casting, can solve the problem that the quality of raw materials entering the furnace is not the first factor, the pretreatment has not attracted enough attention, and the research on the pre-purification method Less problems, to achieve the effect of stabilizing chemical composition and purity, reducing raw material cost, and stabilizing composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

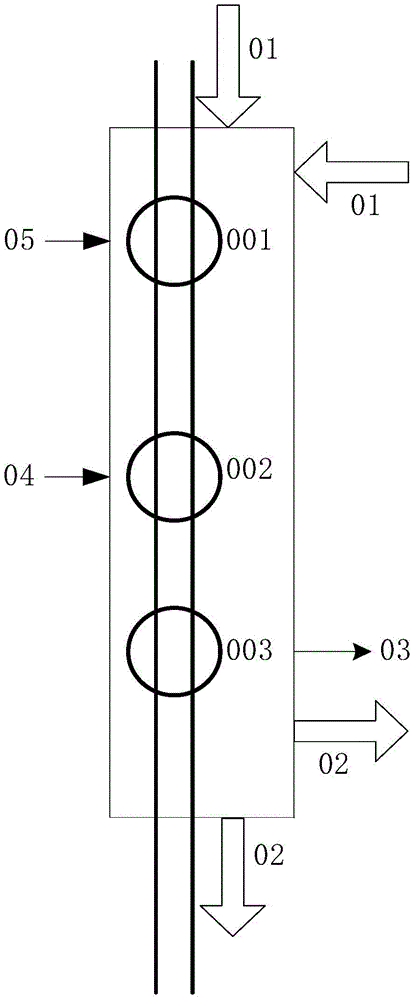

Image

Examples

Embodiment 1

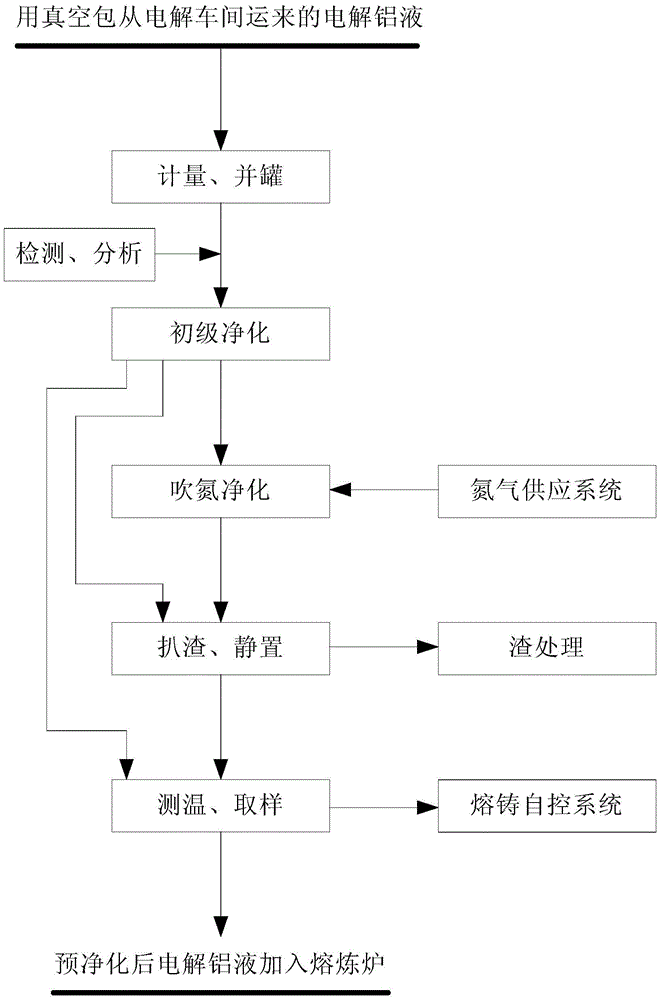

[0067] (1) Purification preparation steps

[0068] The electrolytic aluminum liquid produced in the electrolysis workshop is directly transported to the pre-purification station with a vacuum bag. The quality of each vacuum bag electrolyte is 10t, and a total of 3 vacuum bags are transported. After being transported to the pre-purification station, the electrolytic aluminum in the 3 vacuum bags is The liquid is added to the refining bag of electrolytic aluminum liquid with a capacity of 30t, and the composition of the electrolytic aluminum liquid in the refining bag is sampled and measured, and the temperature of the measurement result is 760°C.

[0069] (2) Alkali metal treatment step

[0070] Add 15 kg of No. 2 flux to the electrolytic aluminum liquid sampled in step (1) and keep it for 10 minutes.

[0071] (3) Slag removal and standing step

[0072] The electrolytic aluminum liquid after the alkali metal treatment in step (2) is quickly transported to the slag-slagging st...

Embodiment 2

[0076] (1) Purification preparation steps

[0077] The electrolytic aluminum liquid produced in the electrolytic workshop is directly introduced into the refining bag in the electrolytic workshop and then transported to the pre-purification station. The capacity of the refining bag is 30t of electrolytic aluminum liquid in the refining bag, of which the electrolytic aluminum liquid is 30t. The electrolytic aluminum in the refining bag The composition of the liquid was sampled and measured, and the temperature of the measured result was 810°C.

[0078] (2) Alkali metal treatment step

[0079] Add 21 kg of No. 2 flux to the electrolytic aluminum liquid sampled in step (1) and keep it for 10 minutes.

[0080] (3) Slag removal and standing step

[0081] The electrolytic aluminum liquid after the alkali metal treatment in step (2) is quickly transported to the slag-slagging static station by a rail car for the slag-slagging operation, and the removed aluminum slag is processed to...

Embodiment 3

[0085] (1) Purification preparation steps

[0086] The electrolytic aluminum liquid produced in the electrolysis workshop is directly transported to the pre-purification station with a vacuum bag. The quality of each vacuum bag electrolyte is 10t, and a total of 3 vacuum bags are transported. After being transported to the pre-purification station, the electrolytic aluminum in the 3 vacuum bags is The liquid is added to the refining ladle of electrolytic aluminum liquid with a capacity of 30t, and the composition of the electrolytic aluminum liquid in the refining ladle is sampled and measured, and the temperature of the measurement result is 920°C.

[0087] (2) Alkali metal treatment step

[0088] Add 20 kg of No. 2 flux to the electrolytic aluminum liquid sampled in step (1) and keep it for 8 minutes.

[0089] (3) Nitrogen blowing step

[0090] The electrolytic aluminum solution added with alkali metal refining agent in step (2) is fed with pure nitrogen, and the purity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com