Planetary gear train two-gear speed control system

A technology of planetary gear train and planetary carrier, which is applied in the direction of belt/chain/gear, drive device, transmission device control, etc., can solve the problems of increased manufacturing cost, large volume occupation, complex structure, etc., and achieve saving of production cost and overall The effect of strong and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

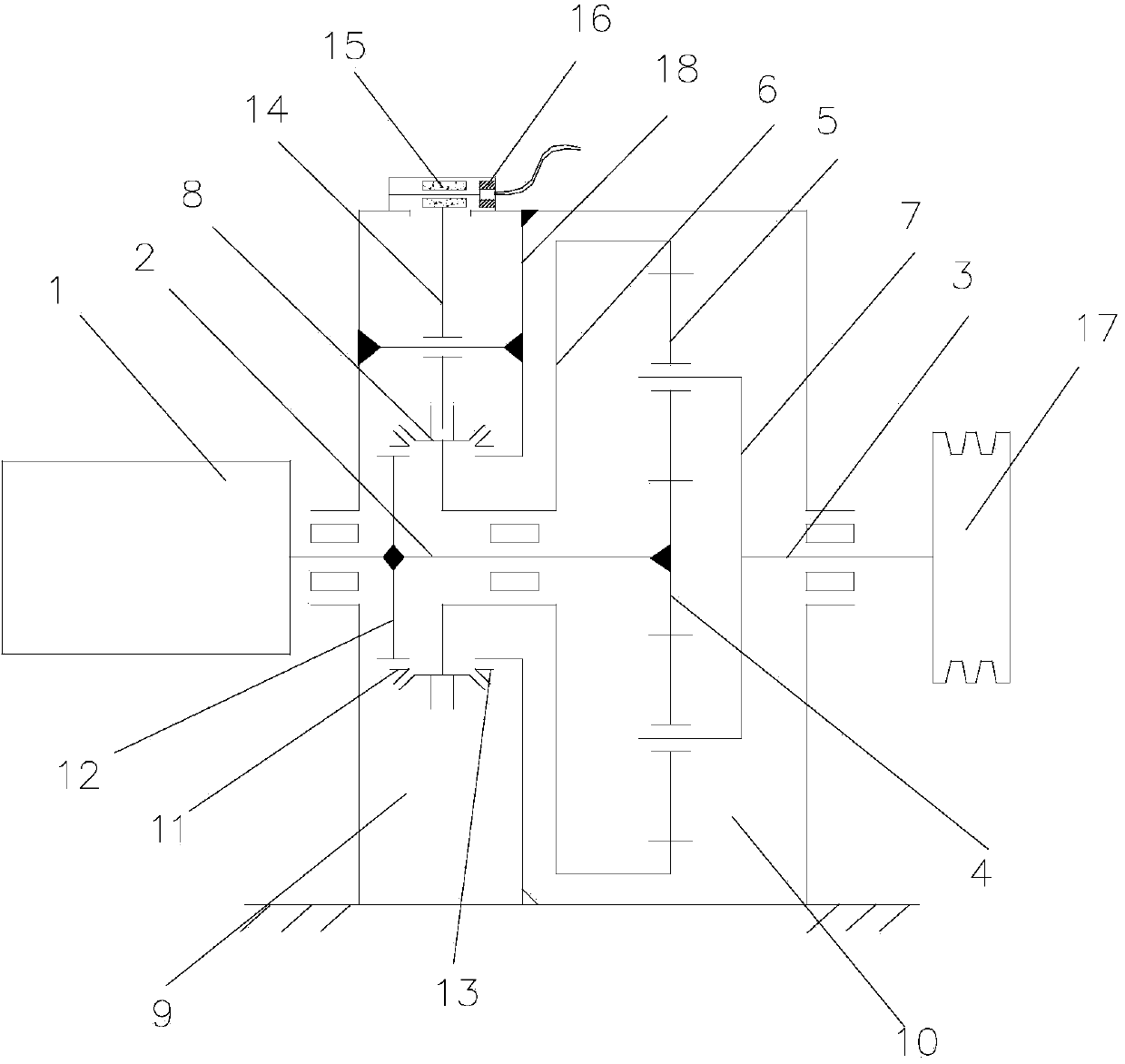

[0017] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the planetary gear train two-speed transmission system of this embodiment includes a motor 1 and a transmission transmission assembly, and the transmission transmission assembly includes a box body 18 and a body that can rotate around its own axis. The power input shaft 2 and the power output shaft 3 are arranged on the box, and also include a planetary gear train for power transmission, and the power input shaft 2 is fixedly matched with the sun gear of the planetary gear train in the circumferential direction , the planet carrier of the planetary gear train is used as the power output end of the planetary gear train to cooperate with the power output shaft. The power input shaft is described above; the power input shaft, the power output shaft and the box body are rotated and matched through necessary radial rolling bearings to achieve the purpose of being able to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com