Sodium ion rechargeable battery and negative electrode active material used for the sodium ion rechargeable battery

A technology of negative active material and positive active material, which is applied in the direction of secondary battery, active material electrode, battery electrode, etc., can solve problems such as difficulty in use, and achieve excellent treatment, excellent potential stability, and excellent secondary battery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

[0087] (Charge and discharge performance evaluation of the sodium ion secondary battery of the present invention)

[0088] (1) Preparation of negative electrode

[0089] Weigh a glassy carbon material (manufactured by Tokai Carbon, trade name "GC20SS", granular, the average particle diameter of the constituent particles is 12 μm, the particle diameter of all particles is 30 μm or less, and the BET specific surface area is 0.5 μm 2 / g) and polyvinylidene fluoride (PVDF) used as a binder, to form a glassy carbon material: a composition of binder=95:5 (weight ratio), the binder is dissolved in N-methylpyrrolidone (NMP), add glassy carbon material to it to make slurry. The obtained slurry was coated on a copper foil having a thickness of 10 μm as a negative electrode current collector with a doctor blade, and dried with a drier to obtain an electrode sheet. The electrode sheet was punched into a diameter of 1.5 cm with an electrode punching machine to obtain a circular active el...

Embodiment 3

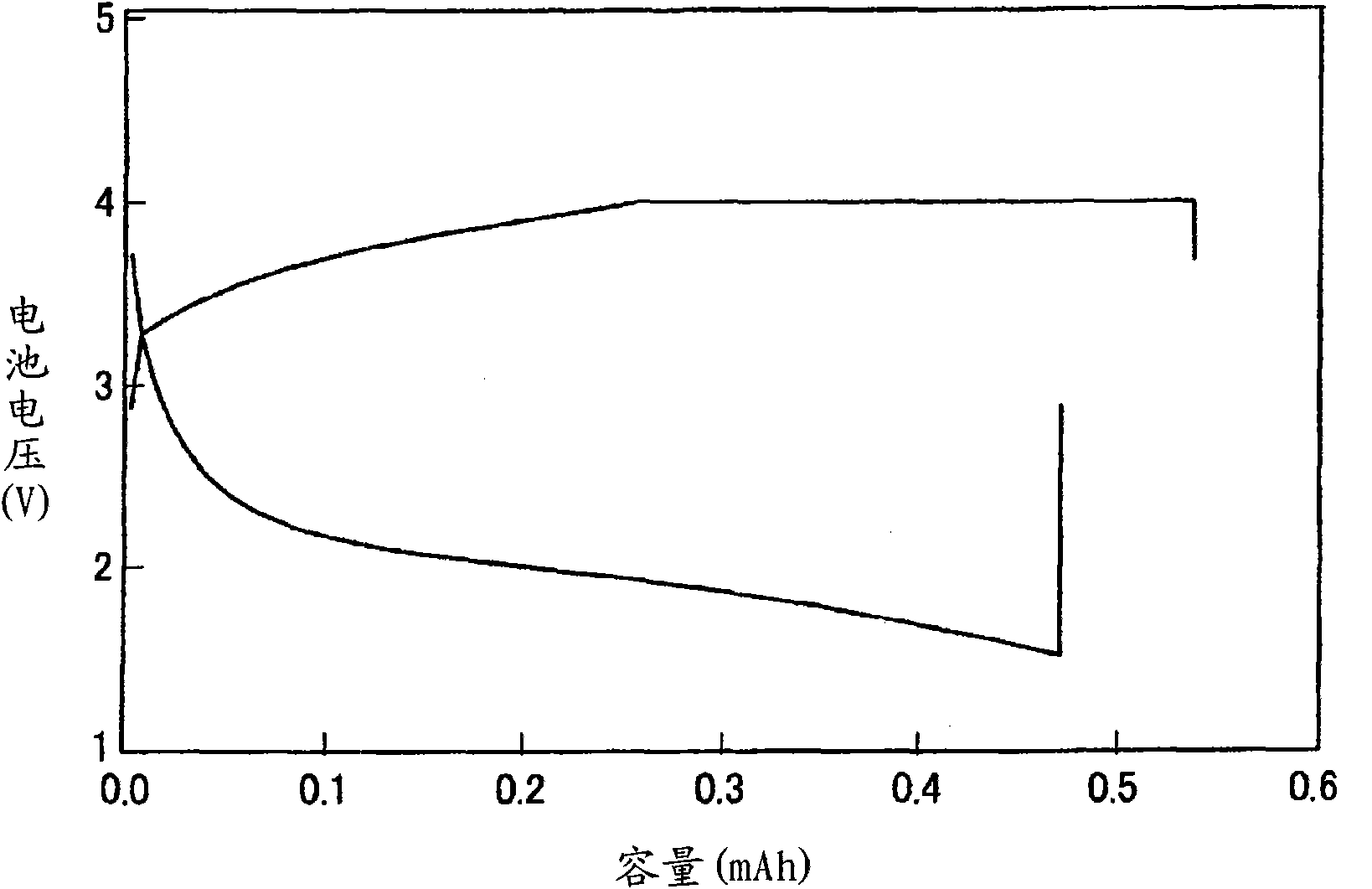

[0104] (Charge and discharge performance evaluation of sodium ion secondary battery)

[0105] (1) Synthesis of positive active material

[0106] In a glove box with argon atmosphere, weigh Na 2 o 2 (manufactured by Fluka Chemie AG) and Fe 3 o 4 (Aldrich Chemical Company, Inc.), so that Na and Fe form NaFeO 2 stoichiometric ratio, followed by thorough mixing with an agate mortar. The obtained mixture was put into an alumina crucible, placed in an electric furnace, kept at 650° C. for 12 hours, and taken out to obtain a positive electrode active material MC1 for a sodium ion secondary battery.

[0107] (2) Production of positive electrode

[0108] The positive electrode active material MC1 obtained in the above (1) and the conductive material were weighed so as to have a composition of 70:25, and mixed with an agate mortar to obtain a mixture X. After that, polyvinylidene fluoride (PVDF) as a binder was weighed to form a composition of MC1:conductive material:binder=70:25...

Embodiment 4、5

[0125] Except for Tokai Carbon (GC10 (trade name) granular, the average particle size of the constituent particles is 6 μm, the particle size of all particles is 20 μm or less, and the BET specific surface area is 1 m 2 / g) as the glassy carbon material is used for the negative electrode active material, except making the negative electrode EA4 as working pole, make test cell TB4 (embodiment 4, electrolytic solution is 1MNaClO 4 / PC), TB5 (embodiment 5, electrolyte is 1M NaClO 4 / EC+DMC), carry out charge and discharge test.

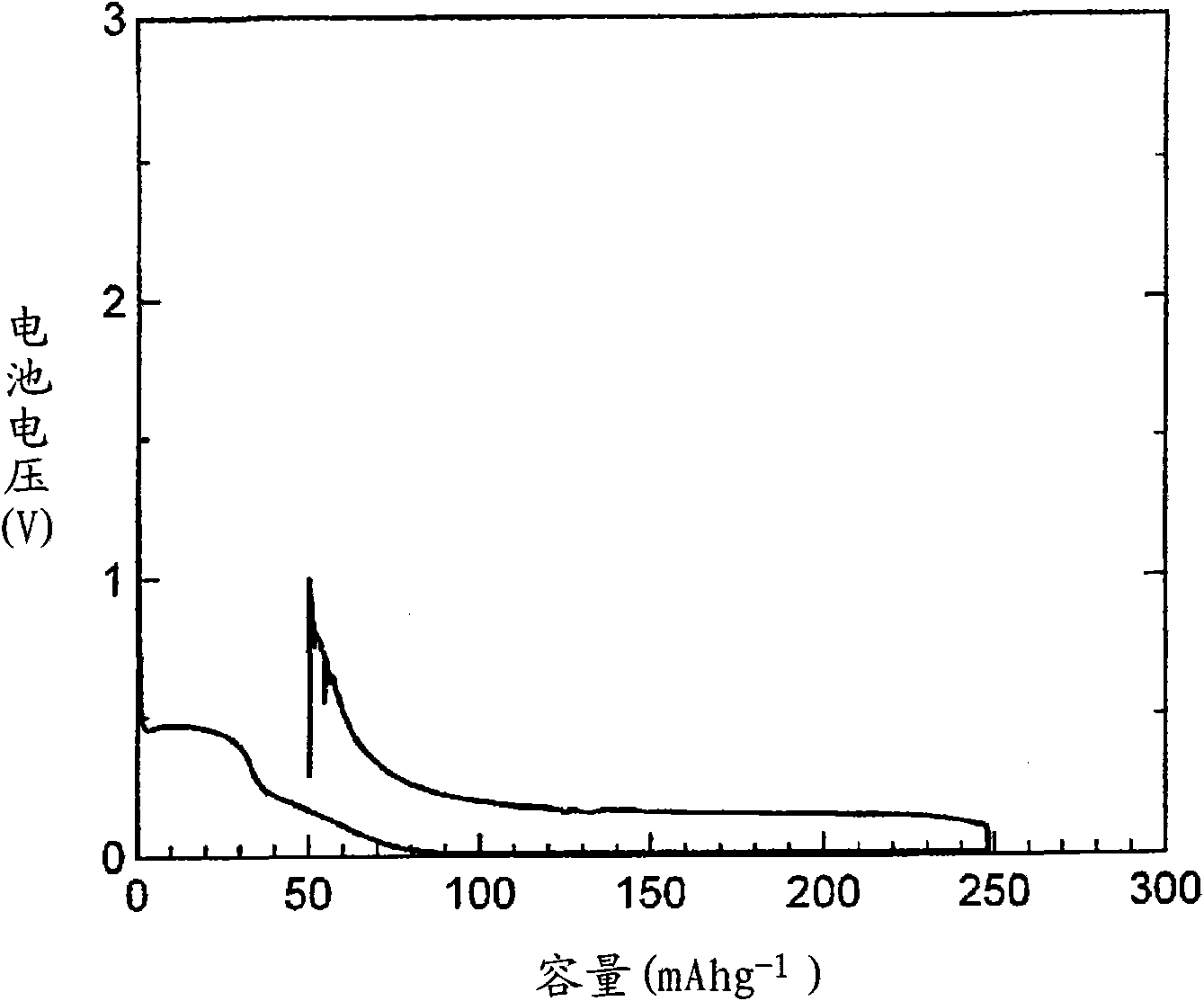

[0126] The charge and discharge test result of TB4 (embodiment 4) is as Figure 4 As shown, the charge capacity in the first cycle was 279mAh / g, and the discharge capacity was 241mAh / g.

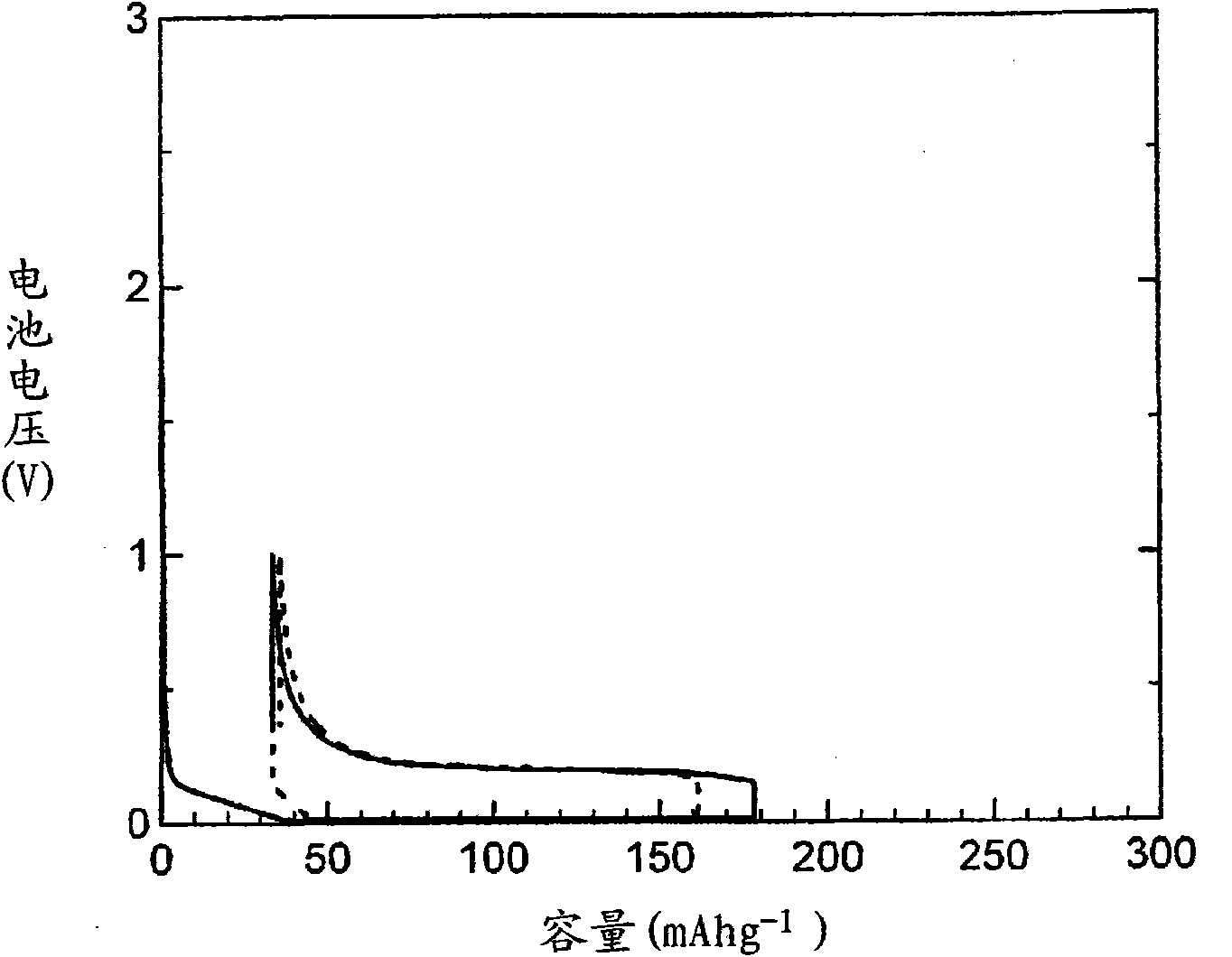

[0127] The charge and discharge test result of TB5 (embodiment 5) is as follows Figure 5 As shown, the charge capacity in the first cycle was 245mAh / g, and the discharge capacity was 181mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com