Method for realizing welding between soft base chip circuit board and metal base body without special tool

A metal substrate and welding method technology, which is applied in the field of welding soft substrate circuit boards and metal substrates without special tooling, can solve problems such as increased production costs, difficult production site management, and unstable products, and reduce production costs. , Eliminate the design of special tooling and outsourcing processing processes, and ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

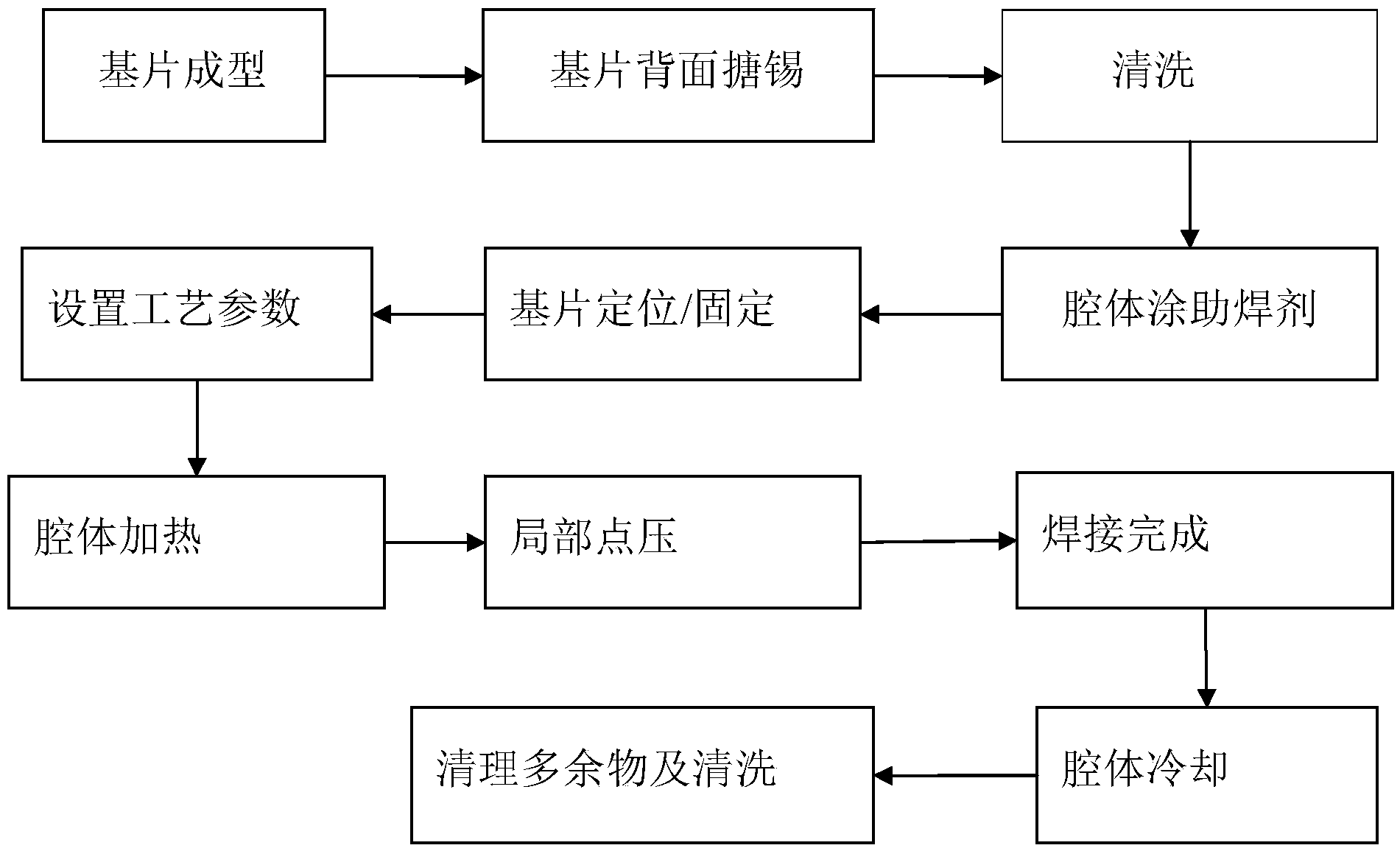

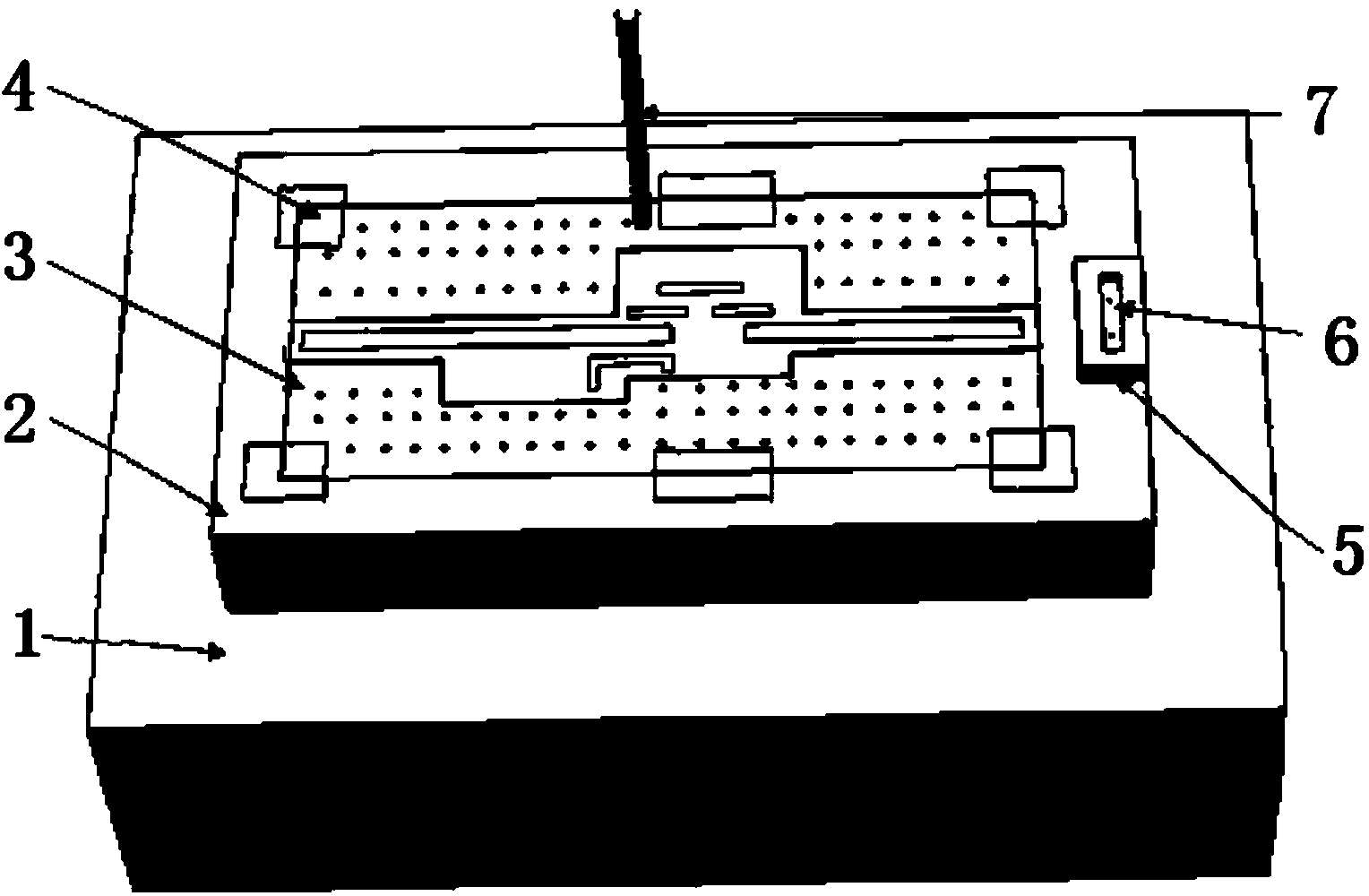

[0019] refer to figure 1 , figure 2 . The present invention will be described step by step below in conjunction with the accompanying drawings and examples.

[0020] The design of the exhaust hole on the soft substrate circuit board: metallization of φ0.3mm~φ0.8mm is set in the metal grounding area of the soft substrate circuit board 3, and the hole density is 0.6cm 2 Inside, 3 to 4 exhaust through holes are evenly distributed in any 10mm diameter surface, and the hole spacing can be in accordance with the general design control requirements. As many ground holes as possible should be designed in the center and around the soft substrate printed circuit board 3 .

[0021] Tinning on the back of the soft substrate circuit board 3: the soft substrate circuit board 3 obtained by forming the circuit pattern is more or less warped or uneven in shape, and tinned on the back of the soft substrate circuit board 3 , the hardness of the circuit of the soft substrate circuit board 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com