Numerically controlled wood engraving and milling machine with universal regulating function

A universal adjustment, engraving and milling machine technology, applied in the direction of wood processing tools, processing models, manufacturing tools, etc., can solve the problems of reducing processing accuracy, affecting work efficiency, and easy jumping of wood bars, reducing the scrap rate and improving Production efficiency and product quality, the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

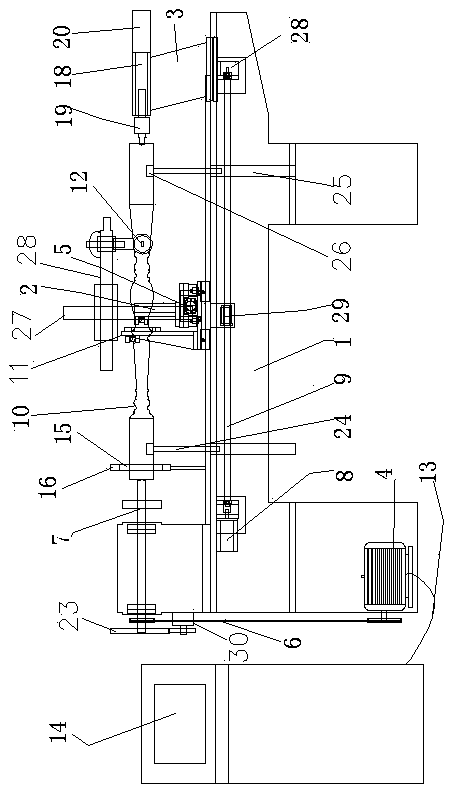

[0010] Accompanying drawing is a kind of specific embodiment of the present invention.

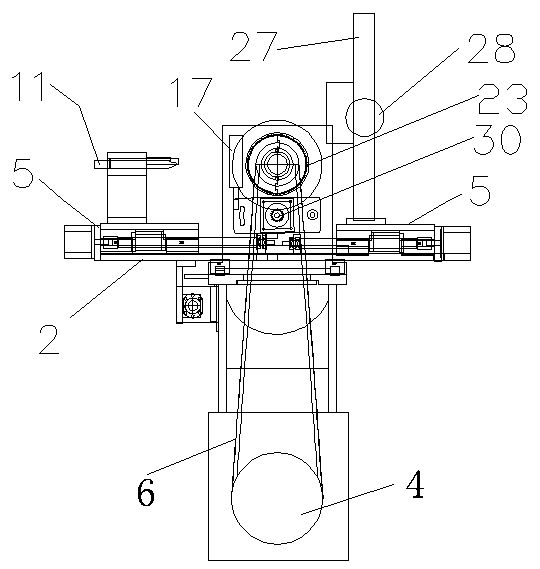

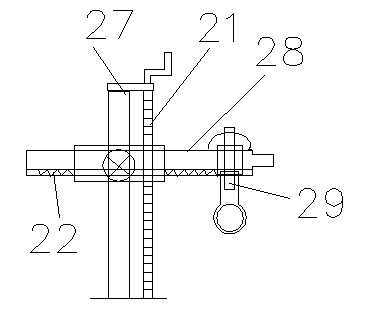

[0011] The CNC woodworking engraving and milling machine with universal adjustment function of the present invention includes a bed 1, a controller 14, a power shaft 7 and a drive motor for the power shaft installed on the front of the bed, a tailstock 3 fixed on the rear of the bed, The tool seat 2 installed in the middle of the bed; the end of the power shaft is provided with a chuck consisting of several cone points; the top 19 driven by the tailstock cylinder 20 is installed on the tailstock, and the top is coaxial with the central axis of the power shaft 7. Clamp and drive the wood bar to rotate; the power shaft drive motor includes a high-speed motor 4 and a low-speed motor 30, the low-speed motor cooperates with the power shaft through the gear 23, and the high-speed motor cooperates with the power shaft through the pulley and the belt 6, and the low-speed motor is hingedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com