Method for improving damage threshold of fused quartz optical element

An optical element and damage threshold technology, which is applied in the field of improving the damage threshold of fused silica optical components, can solve the problems of increasing the damage threshold, high cost, and no global processing of components, and achieves the effect of increasing the damage threshold and preventing redeposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The chemical reagents, cleaning agent and ultrasonic equipment used in the present embodiment are as follows:

[0023] Micro-90 International Products CorporationCompany

[0024] Etching Solution = Electronic Grade HF: Electronic Grade NH 4 F:=1:2:4

[0025] Deionized water 18MΩ*cm

[0026] Ultrasonic cleaner is multiSONIK from Blackstone-NEY Ultrasonics TM generator Seven-frequency ultrasonic cleaning machine, the frequency is 40kHz, 80kHz, 120kHz, 140kHz, 170kHz, 220kHz, 270kHz

[0027] Immerse the fused silica optical element to be treated in micro-90: deionized water = 1:10 cleaning solution for 30 minutes, rinse with deionized water for 30 minutes, spray for 5 minutes; then immerse in the etching solution for 5 minutes, Rinse with deionized water for 90 minutes, then spray for 30 minutes, and let it dry naturally. The above cleaning, etching, and rinsing processes are all carried out in a thousand-class clean environment and a 40-270kHz ultrasonic cleaning mac...

Embodiment 2

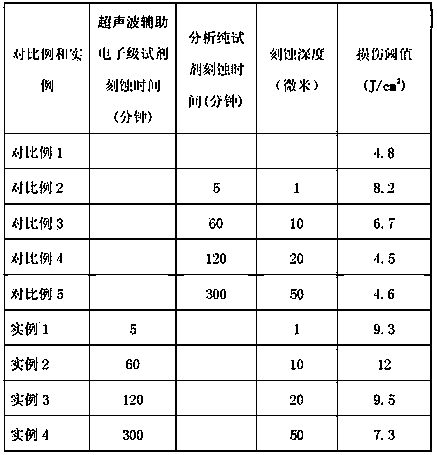

[0029] This embodiment is the same as Embodiment 1, except that the etching time of the fused silica optical element in the etching solution is 60 minutes. The damage threshold test data is listed in Table 1 below.

Embodiment 3

[0031] This embodiment is the same as Embodiment 1, except that the etching time of the fused silica optical element in the etching solution is 120 minutes. The damage threshold test data is listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com