Oxidized polyvinyl alcohol and solid phase modification method thereof

A technology for oxidizing polyvinyl alcohol and polyvinyl alcohol, which is applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of high cost, wastewater treatment, and low efficiency, and achieve high production efficiency, low cost, and expansion The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] At room temperature, put 100 parts of granular PVA1799 into the rotary reactor, spray 5.7 parts of water with a pH of 5.0 and 14 parts of 30% hydrogen peroxide under rotary stirring, slowly heat to 40 ° C, and swell for 2 hours; continue to spray water for 6 1 part and 0.3 part of 1% copper sulfate solution, heat up to 70°C after spraying, keep stirring and react for 2 hours; raise the temperature of the obtained oxidized PVA product to 90°C, and vacuum dry to a moisture content of 8%.

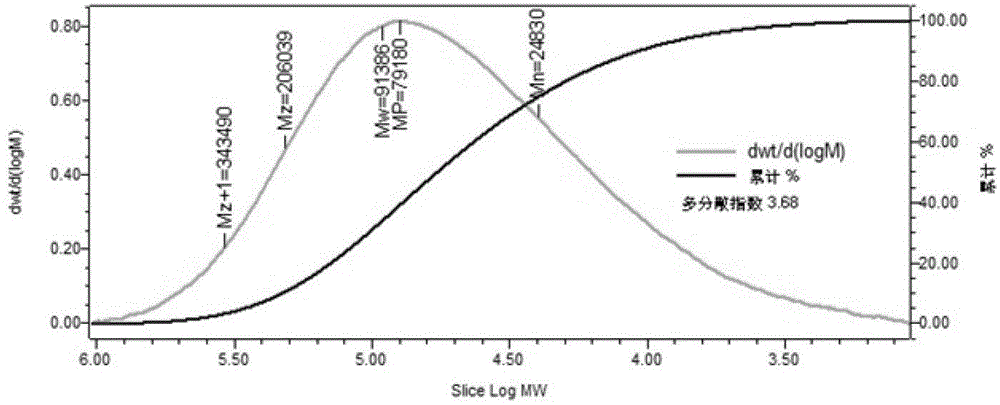

[0047] The weight-average molecular weight of this oxidized PVA product is measured to be 4.14×10 4 , the viscosity is 4.6 mPa·s, the carboxyl content is 2.53%, and the carbonyl content is 3.42%.

Embodiment 2

[0049] At room temperature, put 100 parts of pulverized particles PVA1788 into the rotary reactor, spray 6 parts of water with a pH of 2.0 and 20 parts of 30% hydrogen peroxide under rotary stirring, slowly heat to 45 ° C, and swell for 0.5 hours; continue to spray 0.6 parts under stirring A mixed solution of 1% copper chloride solution was heated to 70°C after spraying, and kept stirring for 3 hours to react; the obtained oxidized PVA product was heated to 90°C, and vacuum-dried to a moisture content of 9%.

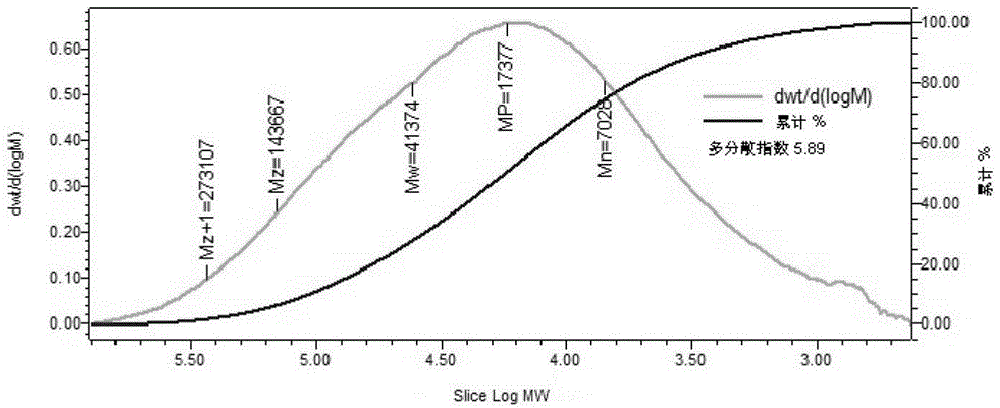

[0050] Measure the weight average molecular weight of this oxidized PVA product 3.58 * 10 4 , viscosity 4.0 mPa·s, carboxyl content 2.05%, carbonyl content 3.09%.

Embodiment 3

[0052] At room temperature, put 100 parts of flaky particles PVA2699 into the rotary reactor, spray 6.6 parts of water with a pH of 10.0 and 18 parts of 30% hydrogen peroxide under rotating stirring, slowly heat to 50°C, and swell for 4 hours; continue to spray water under stirring The mixture of 6 parts and 0.4 parts of 1% ferrous sulfate solution was sprayed and then heated to 60°C, kept stirring and reacted for 3 hours; the obtained oxidized PVA product was heated to 95°C, and vacuum-dried to a moisture content of 7%.

[0053] Measure the weight average molecular weight of this oxidized PVA product 8.76 * 10 4 , viscosity 10 mPa·s, carboxyl content 1.50%, carbonyl content 2.55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com