Nanometer functional coating and preparation method thereof

A nano-functional coating technology, applied in polyester coatings, powder coatings, coatings, etc., can solve problems affecting coating stability and poor performance, and achieve strong heat resistance, good film-forming performance, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

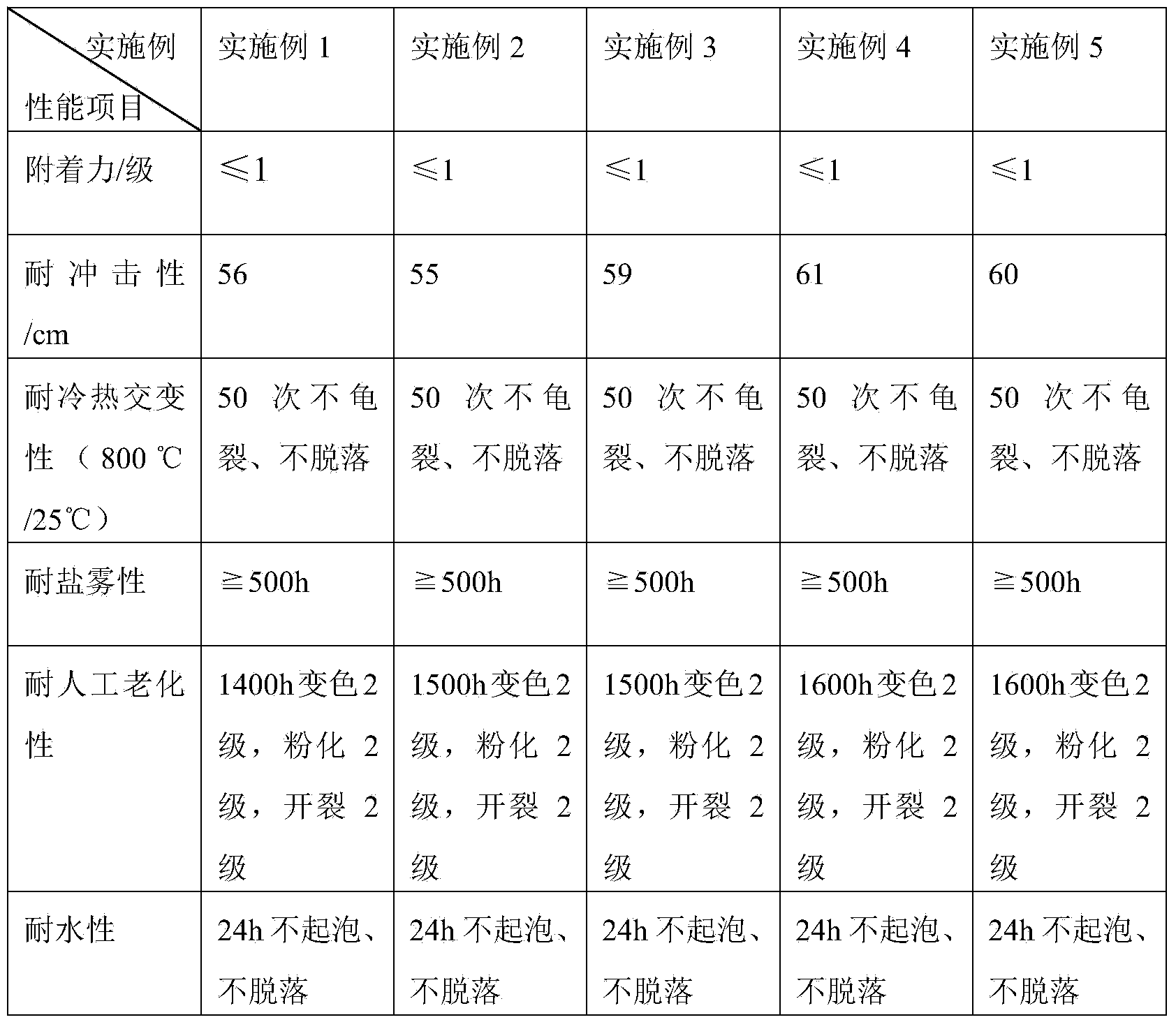

Examples

Embodiment 1

[0015] A nano-functional coating, the components of which are composed of the following components in parts by weight: 55 parts of unsaturated polyester, 35 parts of polyester resin, 30 parts of nano-scale rutile titanium dioxide, 1 part of polyethylene glycol, and 0.4 parts of silicone oil 2 parts, 2 parts of triglycidyl isocyanurate, 4 parts of dicyandiamide curing agent.

[0016] The preparation method of the above-mentioned nano-functional coating includes the following steps: weighing the corresponding raw materials according to the weight of the raw material components; making unsaturated polyester and polyester resin into particles of 3 to 5 mm, and then mixing and stirring them with titanium dioxide , add dispersant, silicone oil, triglycidyl isocyanurate and dicyandiamide curing agent during the stirring process; then extrude from the kneader, keep the cylinder temperature at 80-90°C, and the mold temperature at 100°C; extrude After the product is cooled, crush and gr...

Embodiment 2

[0018] A nano-functional coating, the components of which are composed of the following components in parts by weight: 45 parts of unsaturated polyester, 50 parts of polyester resin, 40 parts of nano-scale rutile titanium dioxide, 3 parts of polyethylene glycol, and 0.7 parts of silicone oil 6 parts, 6 parts of triglycidyl isocyanurate, 8 parts of dicyandiamide curing agent.

[0019] The preparation method of the above-mentioned nano-functional coating includes the following steps: weighing the corresponding raw materials according to the weight of the raw material components; making unsaturated polyester and polyester resin into particles of 3 to 5 mm, and then mixing and stirring them with titanium dioxide , add dispersant, silicone oil, triglycidyl isocyanurate and dicyandiamide curing agent during the stirring process; then extrude from the kneader, keep the cylinder temperature at 80-90°C, and the mold temperature at 100°C; extrude After the product is cooled, crush and g...

Embodiment 3

[0021] A nano-functional coating, its components are composed of the following components by weight: 48 parts of unsaturated polyester, 38 parts of polyester resin, 35 parts of nano-scale rutile titanium dioxide, 2 parts of polyethylene glycol, 0.6 parts of silicone oil 4 parts, 4 parts of triglycidyl isocyanurate, 5 parts of dicyandiamide curing agent.

[0022] The preparation method of the above-mentioned nano-functional coating includes the following steps: weighing the corresponding raw materials according to the weight of the raw material components; making unsaturated polyester and polyester resin into particles of 3 to 5 mm, and then mixing and stirring them with titanium dioxide , add dispersant, silicone oil, triglycidyl isocyanurate and dicyandiamide curing agent during the stirring process; then extrude from the kneader, keep the cylinder temperature at 80-90°C, and the mold temperature at 100°C; extrude After the product is cooled, crush and grind to a particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com