Trunk-free rotary table type vertical-axis wind turbine

A turntable-type, vertical-axis technology, applied to wind turbines, wind turbines at right angles to the wind direction, wind turbine components, etc., can solve problems such as inability to fill lubricating oil, introduce power, unfavorable brackets and blades, etc., and achieve improved Effects of wind energy utilization, vertical length increase, and radius expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

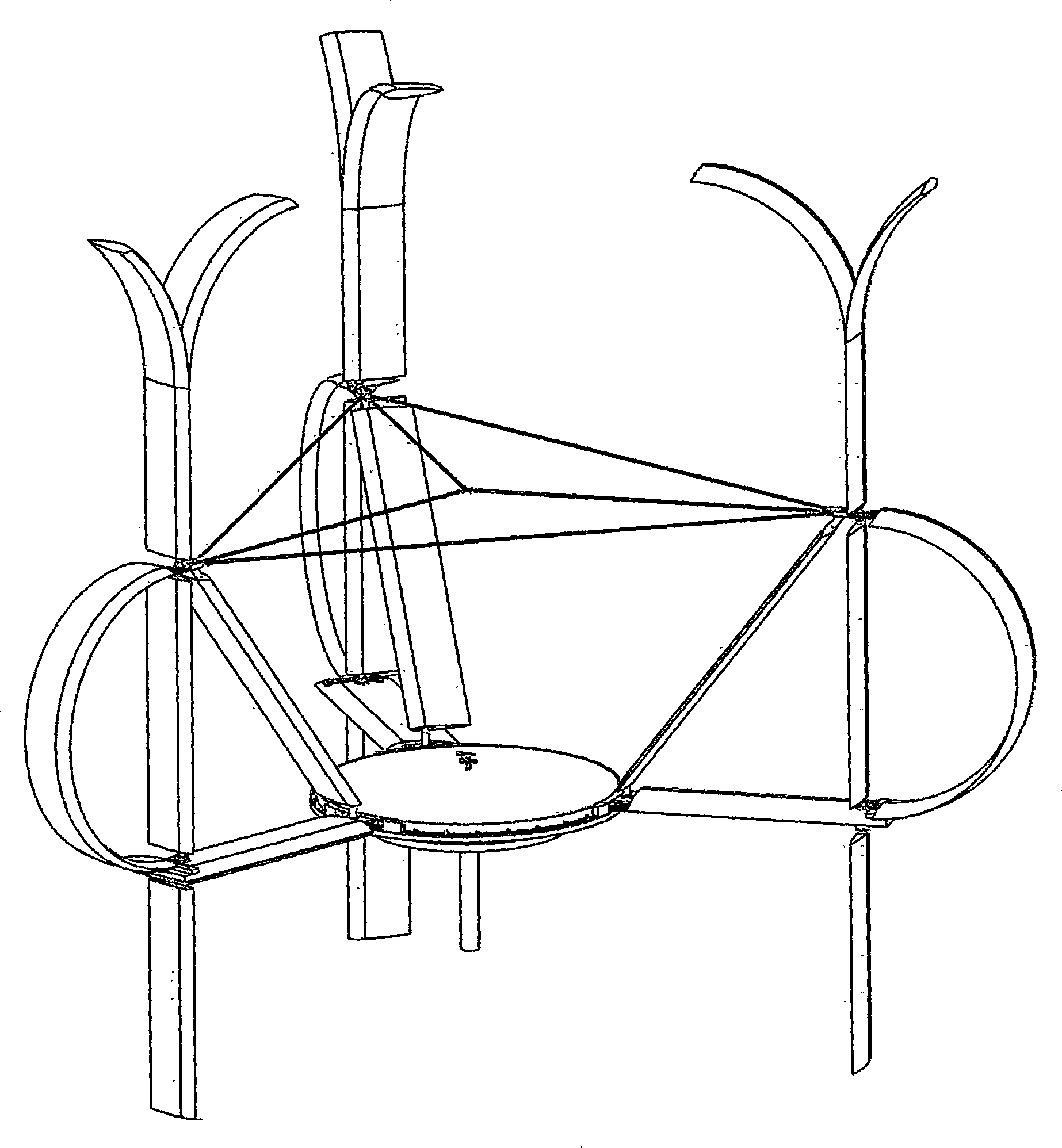

[0049] figure 1 Embodiment 1, the whole structural diagram of the vertical axis wind turbine without a backbone rotating disk with 3 branch blade groups.

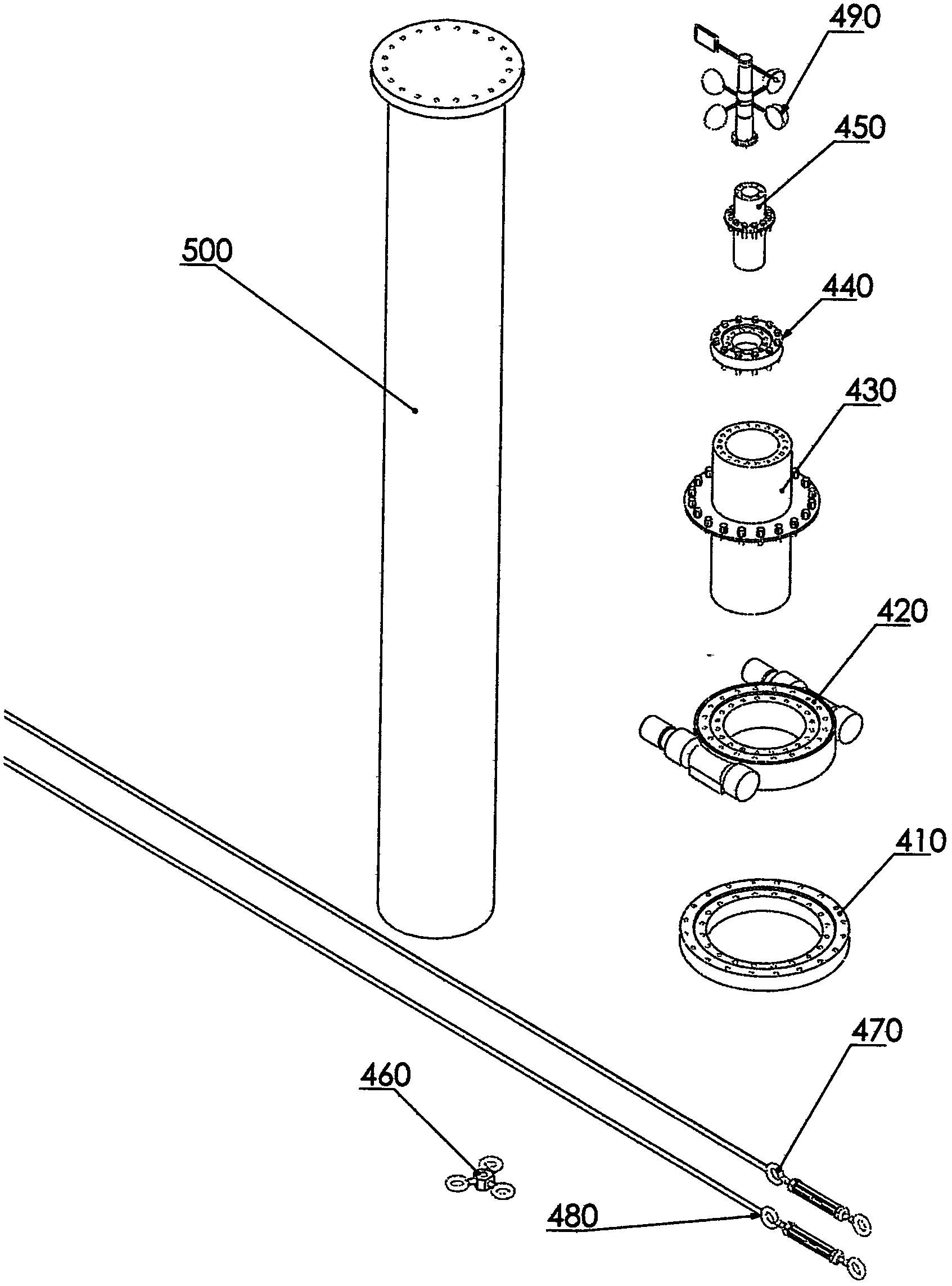

[0050] figure 2 Embodiment 1, schematic diagram of important components. Including: main shaft 500, anemometer 490, r-shaped blade and upper vertical blade connector 450, slewing bearing 440 on which connector 450 is installed, upper and lower vertical blade connectors 430, double-sided slewing drive 420 on which connector 430 is installed , the main shaft slewing bearing 410, the shaft connector 460, the radial connection wire rope and the turnbuckle 470, and the bilateral connection steel wire rope and the turnbuckle 480. The specific embodiment of the present invention can be carried out according to the following steps:

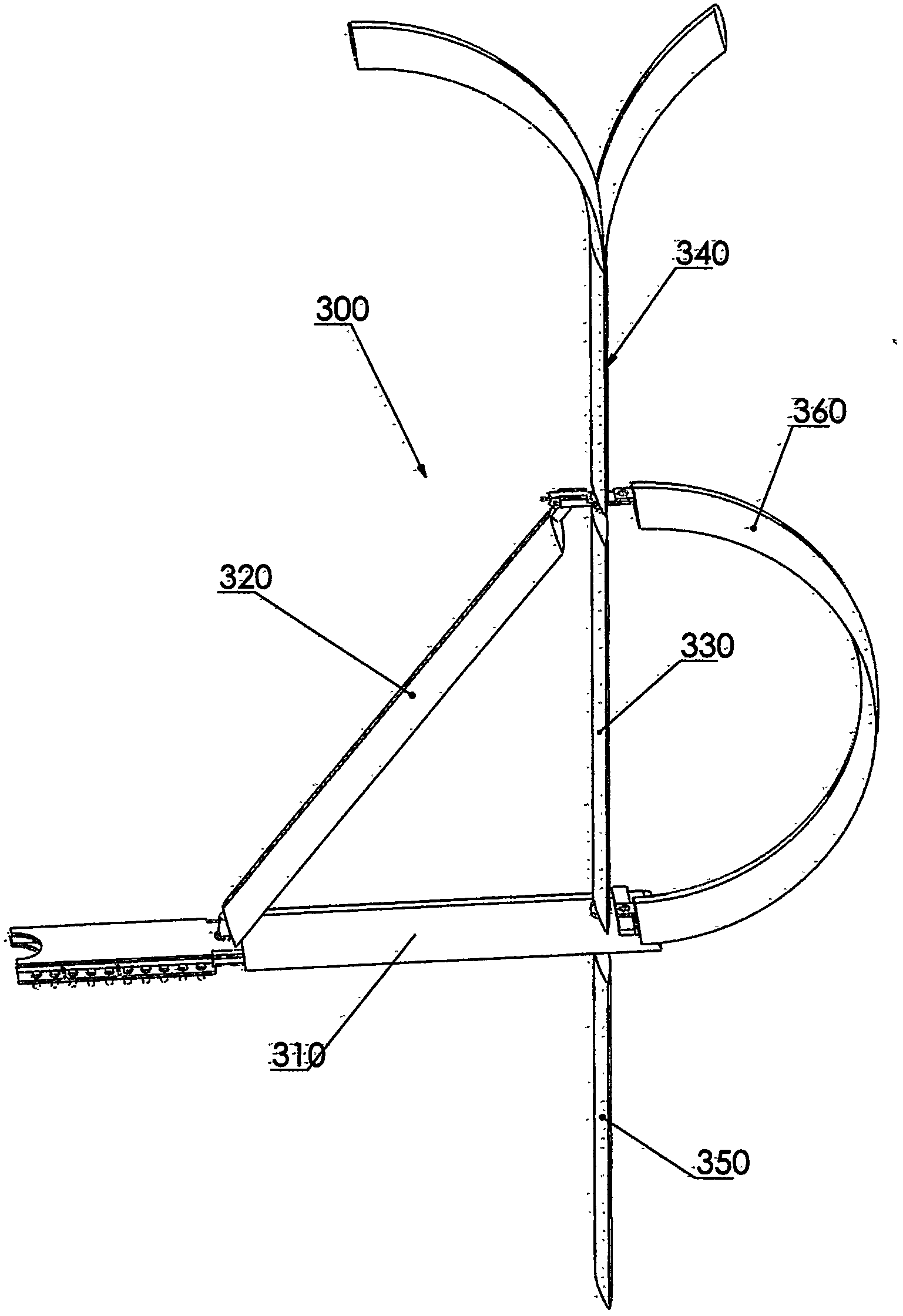

[0051] 1. Design and manufacture branch blade group

[0052] 1) Manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com