Multi-core quick connection type gas path round connector

A technology of connectors and gas circuits, applied in the direction of branch pipelines, pipes/pipe joints/fittings, pipes, etc., to achieve good application and promotion value, high connection firmness, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

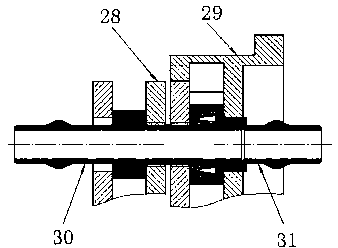

[0052] Specific embodiment 1, taking the 6-core flange-mounted fixed air circuit circular connector socket QLY-20WJ06BQN as an example.

[0053] Assemblies within sockets, such as Figure 5 Shown: Install the 6 special-shaped rubber seals (1) into the 6 connectors (2) of the yin and trachea respectively, and then respectively install them into the 6 holes of the rear mounting plate (4) of the socket, and place them in the socket Install a threaded jack (3) into the center hole of the rear mounting plate (4), and then install it into the front mounting plate (5) of the socket (the side marked with the serial number faces outward), and finally use 4 pieces of M2.5X6 cross Groove pan head screw (6), 4 2.5 elastic washers (7), 4 2.5 flat washers (8) tighten them, and transfer to the next process after checking.

[0054] like Figure 6 As shown, push the inner assembly of the socket installed in the previous step into the socket shell (9). When assembling, just align the large ke...

specific Embodiment 2

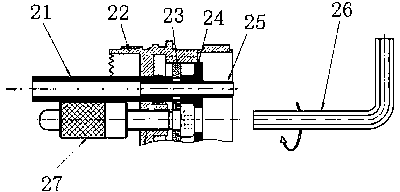

[0055] Specific embodiment 2: Take the 6-core free-end gas path circular connector plug QLY-26WJ06AQN as an example.

[0056] Assemblies within the plug, such as Figure 7 Shown: Install the 6 male air tube connectors (11) into the 6 holes of the plug rear mounting plate (12), and install a threaded jack in the center hole of the plug rear mounting plate (12) ( 3), and then install the front mounting plate (13) of the plug (the side marked with the serial number faces outward), and finally use four M2.5X6 cross-recessed pan head screws (6), four 2.5 elastic washers (7), 4 2.5 flat washers (8) tighten them, and transfer to the next process after checking.

[0057] Push the plug inner assembly installed in the previous step into the plug shell (14). When assembling, just align the large key with the large keyway and the small key with the small keyway. Insert the screw jack (3 ) and rotate clockwise until it can no longer be rotated, at this time the inner assembly of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com