Safety production monitoring system and method for NdFeBH crushing equipment

A technology for safe production and crushing equipment, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., to achieve the effect of improving safety, avoiding safety accidents, and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

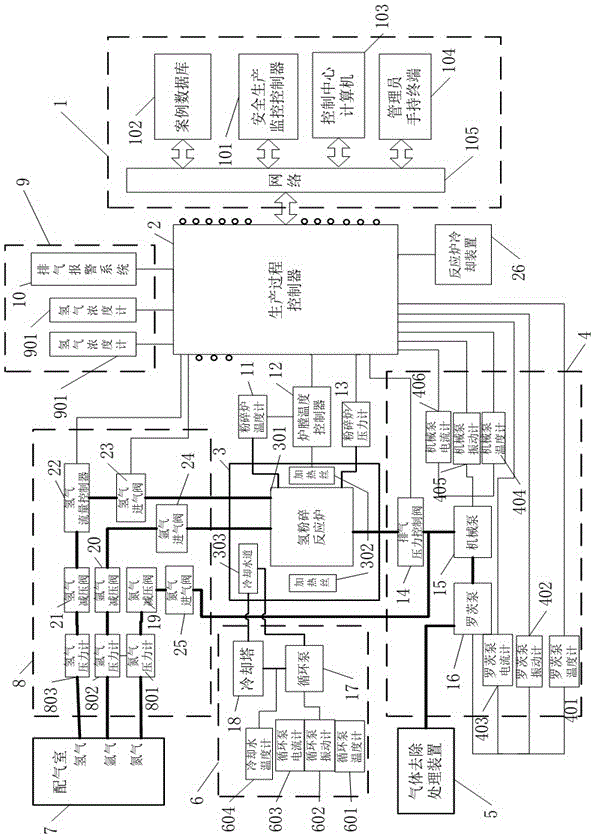

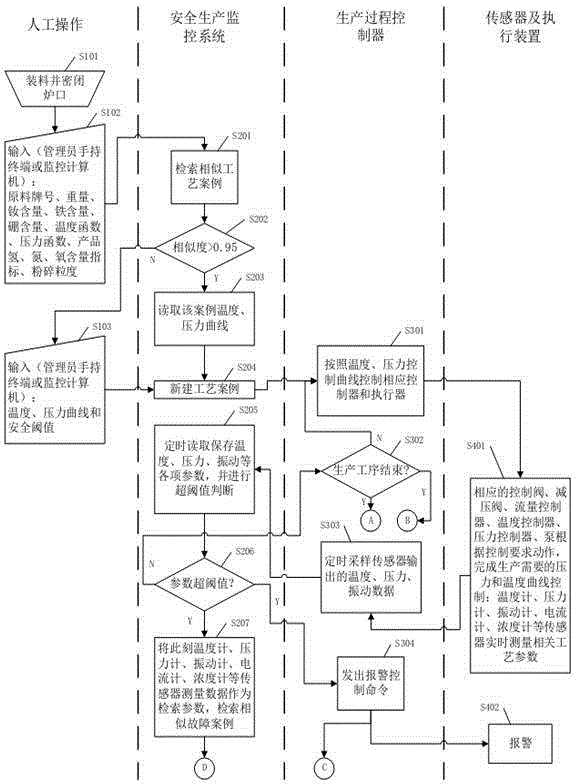

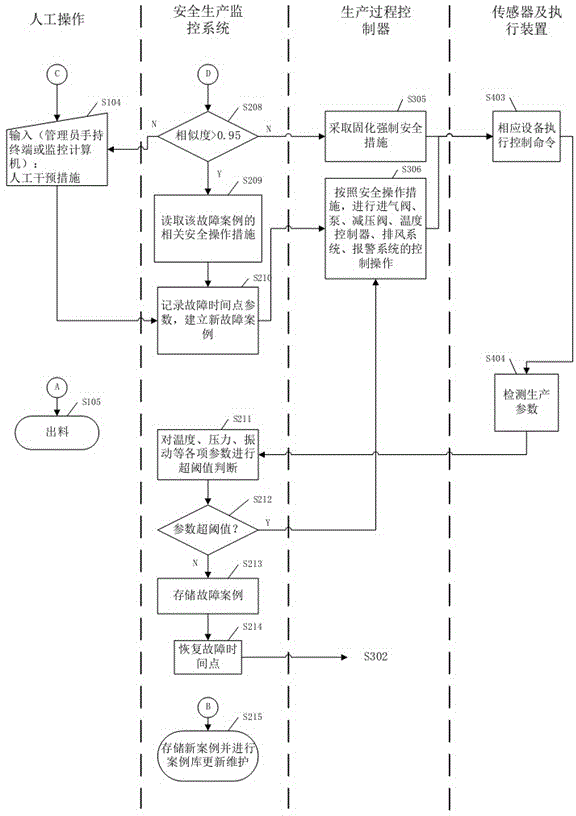

[0050] Such as figure 1 As shown, the technical solution adopted by the present invention is a safety production monitoring system for NdFeBH crushing equipment, and the monitoring system includes:

[0051] Safety production monitoring equipment 1;

[0052] A sensor that measures the operating parameters of the NdFeB hydrogen crushing equipment and outputs monitoring data in real time;

[0053] A production process controller 2 for controlling the control valve pump of the hydrogen crushing reactor to control the production process;

[0054] A production safety monitoring controller 101 used for case retrieval, solving the optimal production process and maintaining the production process;

[0055] Case database 102 for storing and managing case information;

[0056] An administrator handheld terminal 104 and a control center computer 103 for manual remote control of the production process;

[0057] The production process controller 2 is respectively connected with the sens...

Embodiment 2

[0059] On the basis of Example 1, in order to improve the monitoring and control capabilities of the safety production monitoring system, the present invention comprehensively monitors the production process and controls production parameters, a preferred embodiment is also that the NdFeB-hydrogen crushing equipment includes a hydrogen crushing reactor 301 and the gas distribution chamber 7, the gas distribution chamber 7 is connected with the hydrogen pulverization reaction furnace 301 through the gas supply system 8, and the gas supply system 8 respectively supplies hydrogen, argon and and nitrogen into the hydrogen crushing reactor 301, the hydrogen gas distribution pipeline is provided with a hydrogen pressure gauge 803, a hydrogen pressure reducing valve 21, a hydrogen flow controller 22 and a hydrogen inlet valve 23, and the argon gas distribution pipeline is provided with an argon pressure Meter 802, argon decompression valve 20 and argon gas intake valve 24, nitrogen ga...

Embodiment 3

[0065] On the basis of Example 2, in order to be able to monitor and control the production process of NdFeB-H2 crushing equipment in real time and comprehensively, and to avoid production accidents, the preferred implementation mode also includes the safety of NdFeB-H2-H2 crushing equipment. The safety alarm system 9 of the production monitoring system is provided with a hydrogen concentration meter 901 and an exhaust alarm system 10 for monitoring the hydrogen concentration in the air outside the hydrogen crushing reactor;

[0066] In order to be able to comprehensively and accurately monitor the various parameters and equipment operating status of the NdFeB hydrogen crushing equipment, the sensors of the safety production monitoring system of the NdFeB hydrogen crushing equipment include: hydrogen pressure gauge 803, argon pressure gauge 802, nitrogen pressure gauge 801 , Mechanical pump ammeter 406, Mechanical pump vibrating meter 405, Mechanical pump thermometer 404, Roots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com