High-strength and high-conductivity Cu-Cr-Ti alloy conductor and manufacturing method thereof

A cu-cr-ti, alloy wire technology, applied in metal/alloy conductors, cable/conductor manufacturing, chemical instruments and methods, etc., can solve the problem that the strength and electrical conductivity of copper alloy wires cannot be balanced, and achieve good economic benefits , Overcome the contradictions, the effect of excellent plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

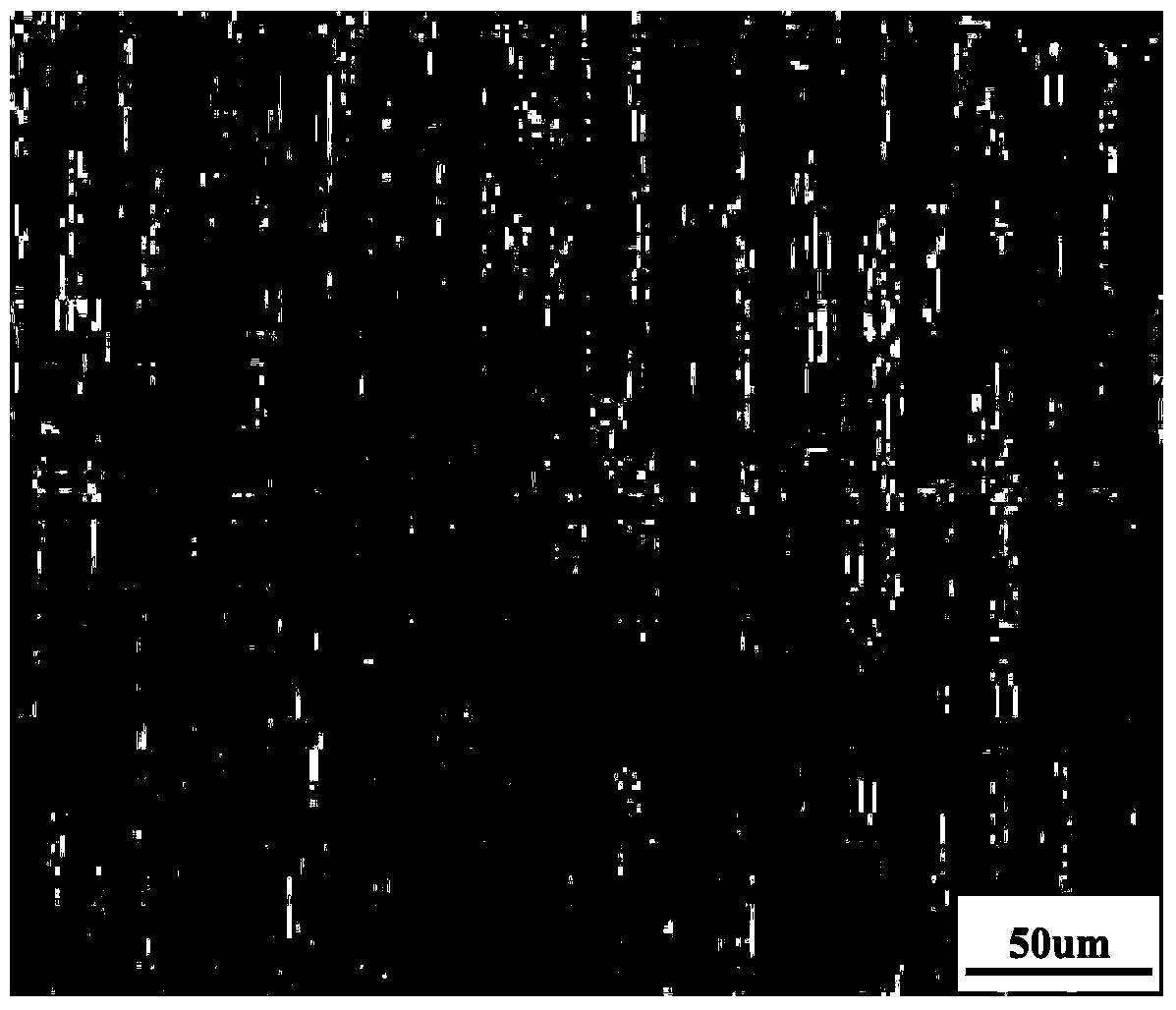

Image

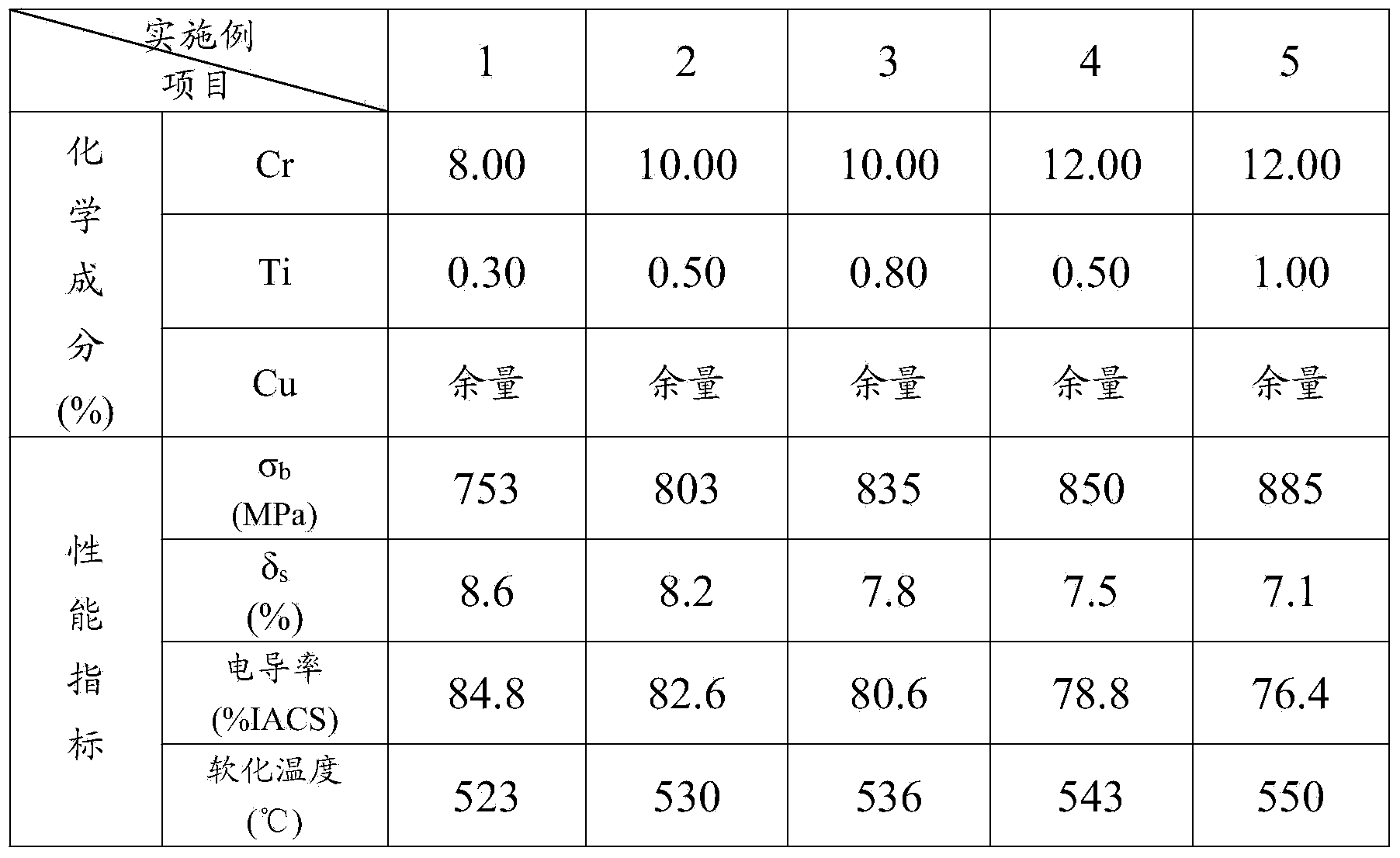

Examples

example 1

[0019] Using 99.99% cathode copper and 99.99% chromium and titanium as raw materials, wherein the percentage of chromium in the total weight is 8%, the percentage of titanium in the total weight is 0.3%, and the chromium is added in the form of Cu-25wt%Cr master alloy, Titanium is added in the form of Cu-25wt%Ti master alloy, placed in a directional solidification furnace, and melted at 1350 °C. Directional solidification casting is performed when the melt temperature is lowered to 1250°C, the vacuum degree of the directional solidification system is set to 0.15Pa, the casting speed is 15mm / min, the cooling water volume is 100L / h, the cooling water temperature is 22°C, and a diameter of 8mm is prepared. Cu-Cr-Ti alloy rod. After the alloy rod is cold-worked or drawn, a wire rod with a diameter of 3 mm is prepared, and the processed wire rod is annealed at a temperature of 450° C. and a holding time of 20 minutes. The annealed wire rod was rolled and deformed to prepare a wire...

example 2

[0021] 99.99% cathode copper and 99.99% chromium and titanium are used as raw materials, wherein the percentage of chromium in the total weight is 10%, the percentage of titanium in the total weight is 0.5%, and the chromium is added in the form of Cu-25wt%Cr master alloy, Titanium is added in the form of Cu-25wt%Ti master alloy, placed in a directional solidification furnace, and melted at 1380 °C. Directional solidification casting is performed when the melt temperature is lowered to 1250°C, the vacuum degree of the directional solidification system is set to 0.15Pa, the casting speed is 20mm / min, the cooling water volume is 120L / h, the cooling water temperature is 20°C, and the diameter is 8mm. Cu-Cr-Ti alloy rod. After the alloy rod is cold-worked or drawn, a wire rod with a diameter of 3 mm is prepared, and the processed wire rod is annealed at a temperature of 480° C. and a holding time of 30 minutes. The annealed wire rod was rolled and deformed to prepare a wire with ...

example 3

[0023] Using 99.99% cathode copper and 99.99% chromium and titanium as raw materials, wherein the percentage of chromium in the total weight is 10%, the percentage of titanium in the total weight is 0.8%, and the chromium is added in the form of Cu-25wt%Cr master alloy, Titanium is added in the form of Cu-25wt%Ti master alloy, placed in a directional solidification furnace, and melted at 1380 °C. The directional solidification casting is carried out when the melt temperature is lowered to 1250°C, the vacuum degree of the directional solidification system is set to 0.15Pa, the casting speed is 20mm / min, the cooling water volume is 150L / h, the cooling water temperature is 25°C, and the diameter is 8mm. Cu-Cr-Ti alloy rod. After the alloy rod is cold-worked or drawn, a wire rod with a diameter of 3 mm is prepared, and the processed wire rod is annealed at a temperature of 500° C. and a holding time of 30 minutes. The annealed wire rod was rolled and deformed to prepare a wire wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com