Method for preparing manganese sulfide nanosheets employing quantum dot seed process

A technology of nanosheets and manganese sulfide, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as harsh reaction conditions, and achieve the effects of high repetition rate, easy access to raw materials, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

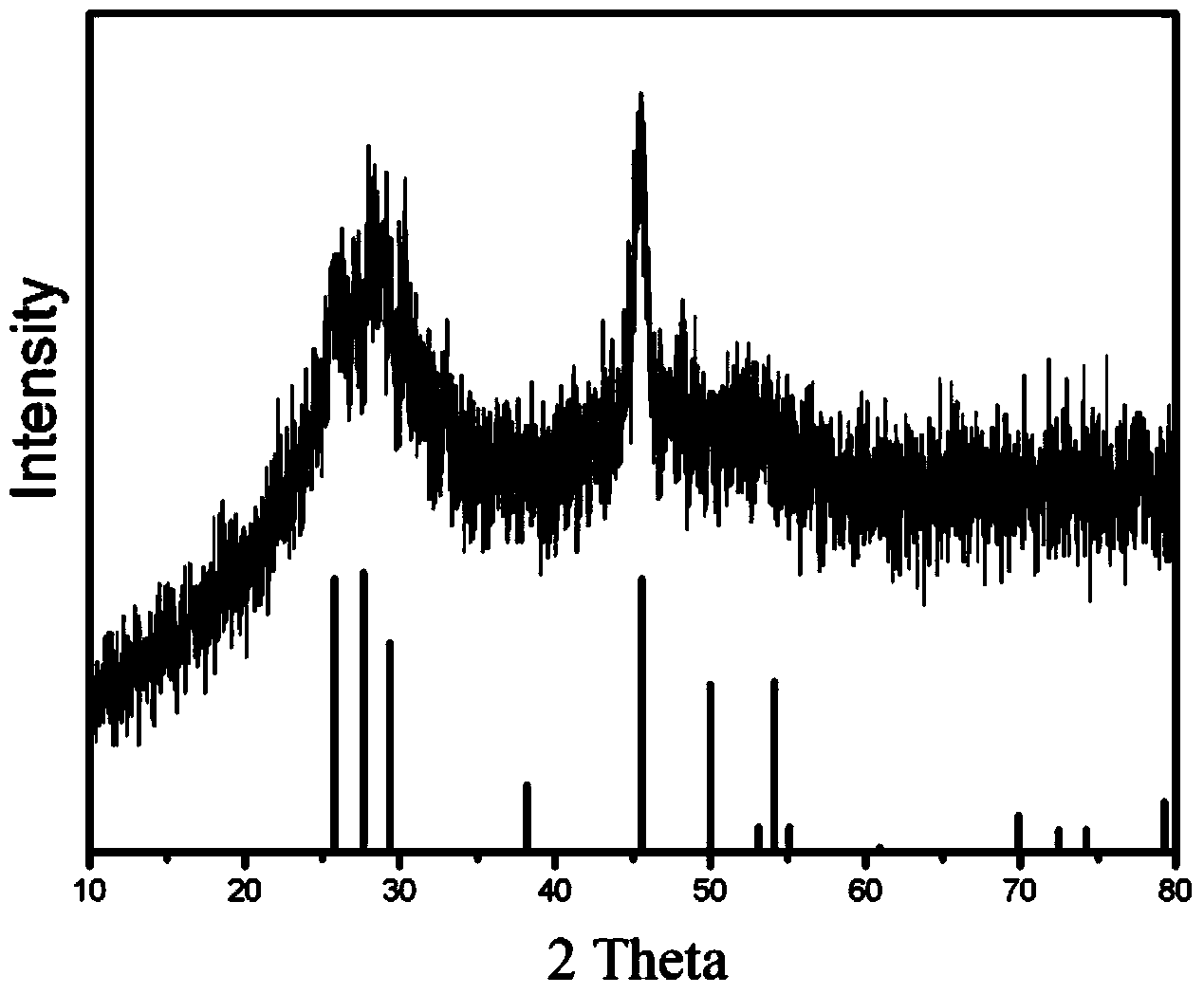

[0022] Under nitrogen protection at 200°C, 1.5 mmol of manganese chloride tetrahydrate was added to 5 ml of oleylamine to obtain a solution containing quantum dots. At the same time, 3 mmol of sublimed sulfur was dissolved in 5 ml of oleylamine at 70° C. under nitrogen protection. Heat 1ml of the mixed solution containing quantum dots to 240 degrees Celsius, and then add 0.5ml of sulfur source solution every 20 minutes, adding 5 times in total. After the reaction, an appropriate amount of ethanol was added, and the MnS nanosheets were obtained by centrifugal washing.

Embodiment 2

[0024] Under nitrogen protection at 240°C, 1.5 mmol of manganese chloride tetrahydrate was added to 5 ml of oleylamine to obtain a solution containing quantum dots. At the same time, 3 mmol of sublimed sulfur was dissolved in 5 ml of oleylamine at 70° C. under nitrogen protection. Heat 0.5 ml of the mixed solution containing quantum dots to 200 degrees Celsius, and then add 0.5 ml of the sulfur source solution every 20 minutes for a total of 5 additions. After the reaction, an appropriate amount of ethanol was added to break the emulsification, and the MnS nanosheets were obtained by centrifuging and washing.

Embodiment 3

[0026] Under nitrogen protection at 200°C, 1.5 mmol of manganese chloride tetrahydrate was added to 5 ml of oleylamine to obtain a solution containing quantum dots. At the same time, 3 mmol of sublimed sulfur was dissolved in 5 ml of oleylamine at 70° C. under nitrogen protection. Heat 2ml of the mixed solution containing quantum dots to 170 degrees Celsius, and then add 0.5ml of sulfur source solution every 20 minutes, and add 5 times in total. After the reaction, an appropriate amount of ethanol was added to break the emulsification, and the MnS nanosheets were obtained by centrifuging and washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com