Method for pretreating high-concentration pharmaceutical wastewater by using bentonite composite intercalation material

A composite intercalation and pharmaceutical wastewater technology, applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effect of low technical requirements, good pretreatment effect and abundant reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

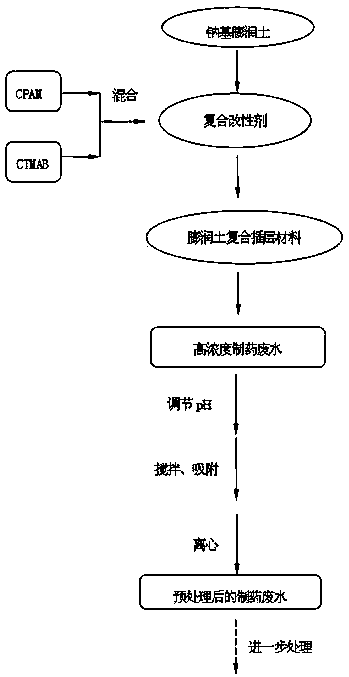

Image

Examples

Embodiment 1

[0028] (1) Take the COD value as 1.0-2.0×10 5 mg / L of fosfomycin sodium epoxy mother liquor wastewater, adjust the pH to 6~8.

[0029] (2) Mix the bentonite composite intercalation material with pharmaceutical wastewater at a mass volume ratio of 2.0g: 100mL.

[0030] (3) Stir for 2 hours under the condition of 200~300r / min, so that the bentonite composite intercalation material can fully absorb the organic matter in pharmaceutical wastewater.

[0031] (4) Centrifuge the treated pharmaceutical wastewater under the conditions of centrifugation speed greater than 1500r / min and centrifugation time greater than 3min. The COD removal rate of the treated pharmaceutical wastewater can reach up to 78.39%, and the adsorption capacity is 3334mg / g, reaching pretreatment Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com