Butane-containing fracturing fluid and preparation method thereof

A technology of fracturing fluid and butane, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that cannot satisfy the research of LPG fracturing fluid, and achieve improved fracturing effect, good viscoelasticity, good The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

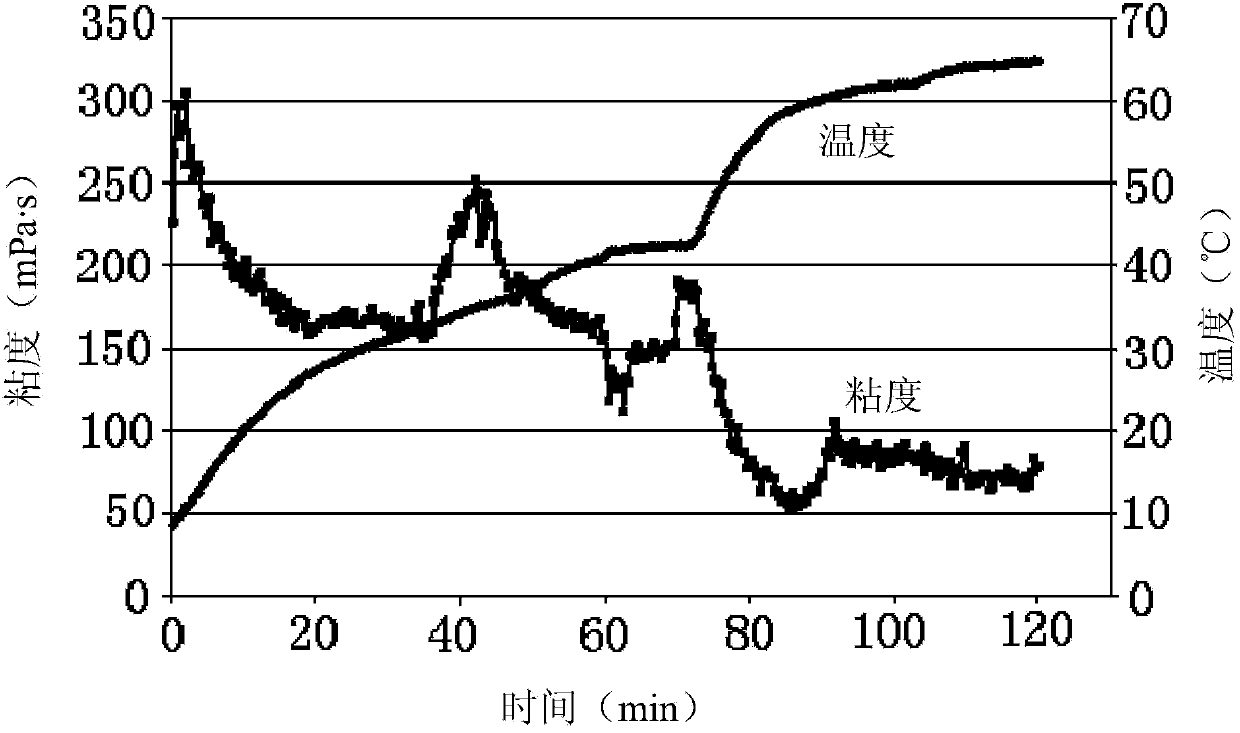

Image

Examples

Embodiment 1

[0035] This embodiment provides a fracturing fluid containing butane, in parts by mass, its raw material composition includes:

[0036] Phosphate ester thickener 0.5 parts;

[0037] 0.25 parts of sodium metaaluminate;

[0038] Butane 100 parts.

[0039] The phosphate ester thickener in this example is a dialkyl phosphate ester composed of a short-chain alkyl group (C1-C4) and a medium-length carbon chain alkyl group (C5-C7), which is prepared according to the following method: In a 250mL four-necked flask equipped with a mechanical stirrer, a condenser, and a thermometer, make P 2 o 5 With triethyl phosphate at a molar ratio of 1:1, react at 90°C for 6 hours to obtain a polyphosphate intermediate, and then add butanol (the butanol and P 2 o 5 The molar ratio is 5:2), and then heated to 125 ° C for 6 hours to obtain a light yellow liquid, which is the dialkyl phosphate (phosphate thickener) of this example.

[0040] The fracturing fluid containing butane of this embodimen...

Embodiment 2

[0046] This embodiment provides a fracturing fluid containing butane, in parts by mass, its raw material composition includes:

[0047] Phosphate ester thickener 0.8 part;

[0048] 0.8 parts of sodium metaaluminate;

[0049] Sodium salicylate 0.1 part;

[0050] 100 parts of butane;

[0051] The phosphate thickener in this embodiment is the same as the phosphate thickener in Example 1.

[0052] The fracturing fluid containing butane of this embodiment is prepared according to the following method:

[0053] (1) Put the butane gas tank, pressure container, magnetic stirring rod, beaker and other instruments in a low-temperature cabin at -10°C to -15°C for 45 minutes to ensure that the butane temperature in the butane gas tank drops to the boiling point- below 5°C, and ensure that the temperature of all instruments in contact with liquid butane is below -5°C;

[0054] (2) Take out the liquid butane in the butane gas tank in the low-temperature cabin of -10°C to -15°C and put ...

Embodiment 3

[0058] This embodiment provides a fracturing fluid containing butane, in parts by mass, its raw material composition includes:

[0059]

[0060] The phosphate thickener in this embodiment is the same as the phosphate thickener in Example 1.

[0061] The fracturing fluid containing butane of this embodiment is prepared according to the following method:

[0062] (1) Put the butane gas tank, pressure container, magnetic stirring rod, beaker and other instruments in a low-temperature cabin at -10°C to -15°C for 45 minutes to ensure that the butane temperature in the butane gas tank drops to the boiling point- below 5°C, and ensure that the temperature of all instruments in contact with liquid butane is below -5°C;

[0063] (2) Take out the liquid butane in the butane gas tank in the low-temperature cabin of -10°C to -15°C and put it into a pressure-resistant container;

[0064] (3) Add phosphate ester thickener (stored in a beaker stored in a low-temperature cabin), citric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com