Carbon dioxide coal slurry preparation and gasification system

A carbon dioxide and gasification system technology, applied in the manufacture of combustible gas, granular/powdered fuel gasification, chemical industry, etc., can solve the problems of complex pulverized coal delivery system, short service life of burners, and needs to be further improved to achieve The effect of improving heat utilization efficiency, saving energy consumption, and widening the adaptability of coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

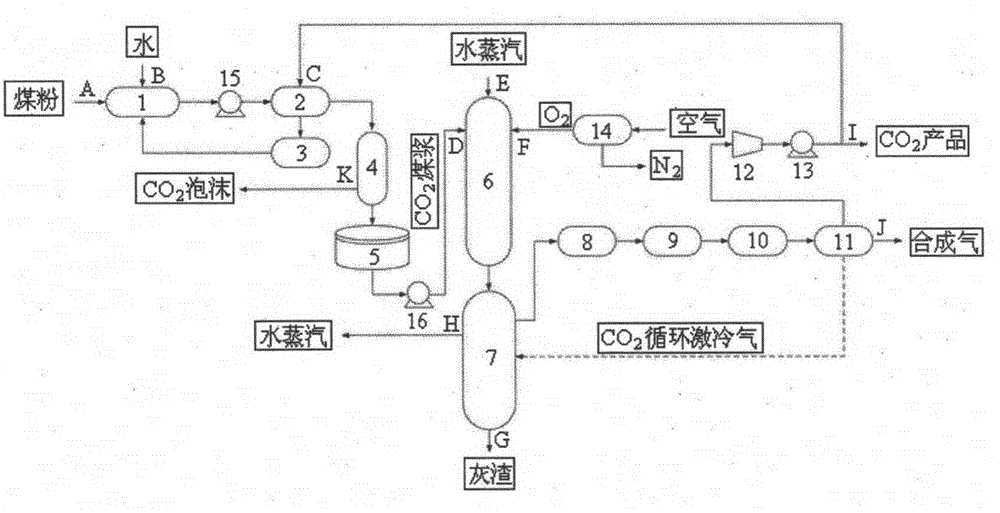

[0032] like figure 1As shown, it is a schematic diagram of a carbon dioxide coal slurry preparation, transportation and gasification system provided by the present invention. The system consists of a coal water slurry preparation unit, a carbon dioxide coal slurry preparation unit, a coal gasification unit, a syngas cooling and purification unit and a carbon dioxide Composition of capture separation unit. Described coal-water slurry preparation unit comprises coal-water slurry preparation tank 1, and coal-water slurry preparation tank 1 is provided with pulverized coal inlet A and water inlet B, and coal-water slurry preparation tank 1 passes coal slurry pump-15 and coal slurry replacement tank 2 connection; the coal slurry replacement tank 2 forms a circulation with the coal water slurry preparation tank 1 through the dehydration tank 3. The carbon dioxide coal slurry preparation unit includes a carbon dioxide coal slurry tank 5, and the coal gasification unit includes a gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com