Engine protective agent

A protective agent, engine technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of poor lubricating oil matching, engine lubricating oil mismatching, and inability to work normally, so as to eliminate acidification corrosion and improve lubricating oil. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

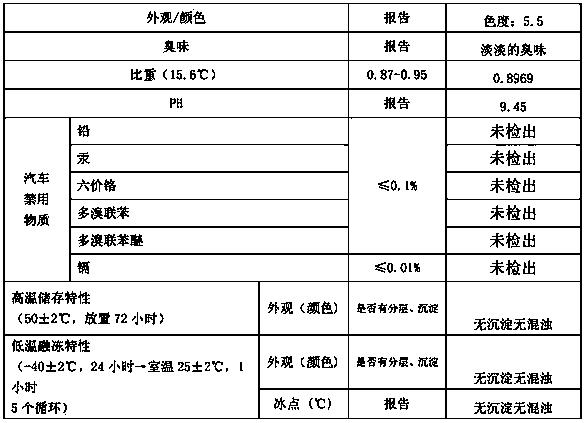

Image

Examples

Embodiment 1

[0015] The non-disintegrating cleaning agent for the engine lubrication system described in the present embodiment is characterized in that the chemical components are proportioned by weight as follows:

[0016] Medium viscosity secondary hydrogenation base oil: 65 components; Polyisobutylene bis-succinimide: 16.0 components; Antioxidant: 4.0 components; Sulfurized isobutylene: 6 components; Ethylene oxide: 2 components, ZDDP : 6.5 components, vegetable oil: 0.5 components.

[0017] The configuration method of the non-dismantling cleaning agent for the engine lubricating system described in this embodiment is:

[0018] 1) Keep the temperature of the reactor at 45°C

[0019] 2) Add the proportioning raw materials one by one and keep stirring

[0020] 3) Each raw material is added at an interval of 15 minutes

[0021] 4) Keep stirring for 8 hours after adding the raw materials

Embodiment 2

[0023] The non-disintegrating cleaning agent for the engine lubrication system described in the present embodiment is characterized in that the chemical components are proportioned by weight as follows:

[0024] Medium viscosity secondary hydrogenation base oil: 79.4 components; polyisobutylene bis-succinimide: 6.1 components; antioxidant: 1.0 components; sulfurized isobutylene: 9.4 components; ethylene oxide: 0.1 components.ZDDP : 1.5 components, vegetable oil: 2.5 components.

[0025] The configuration method of the non-dismantling cleaning agent for the engine lubricating system described in this embodiment is:

[0026] 1) Keep the temperature of the reactor at 45°C

[0027] 2) Add the proportioning raw materials one by one and keep stirring

[0028] 3) Each raw material is added at an interval of 15 minutes

[0029] 4) Keep stirring for 8 hours after the raw materials are added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com