Method for preparing dibutyl phthalate by electrochemically degrading lignin in ferrous sulfate solution

A technology of dibutyl phthalate, ferrous sulfate solution, applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve the problem of low yield, high production cost, and difficulty in industrialized production, etc. problem, to achieve the effect of low cost, alleviation of environmental pressure, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

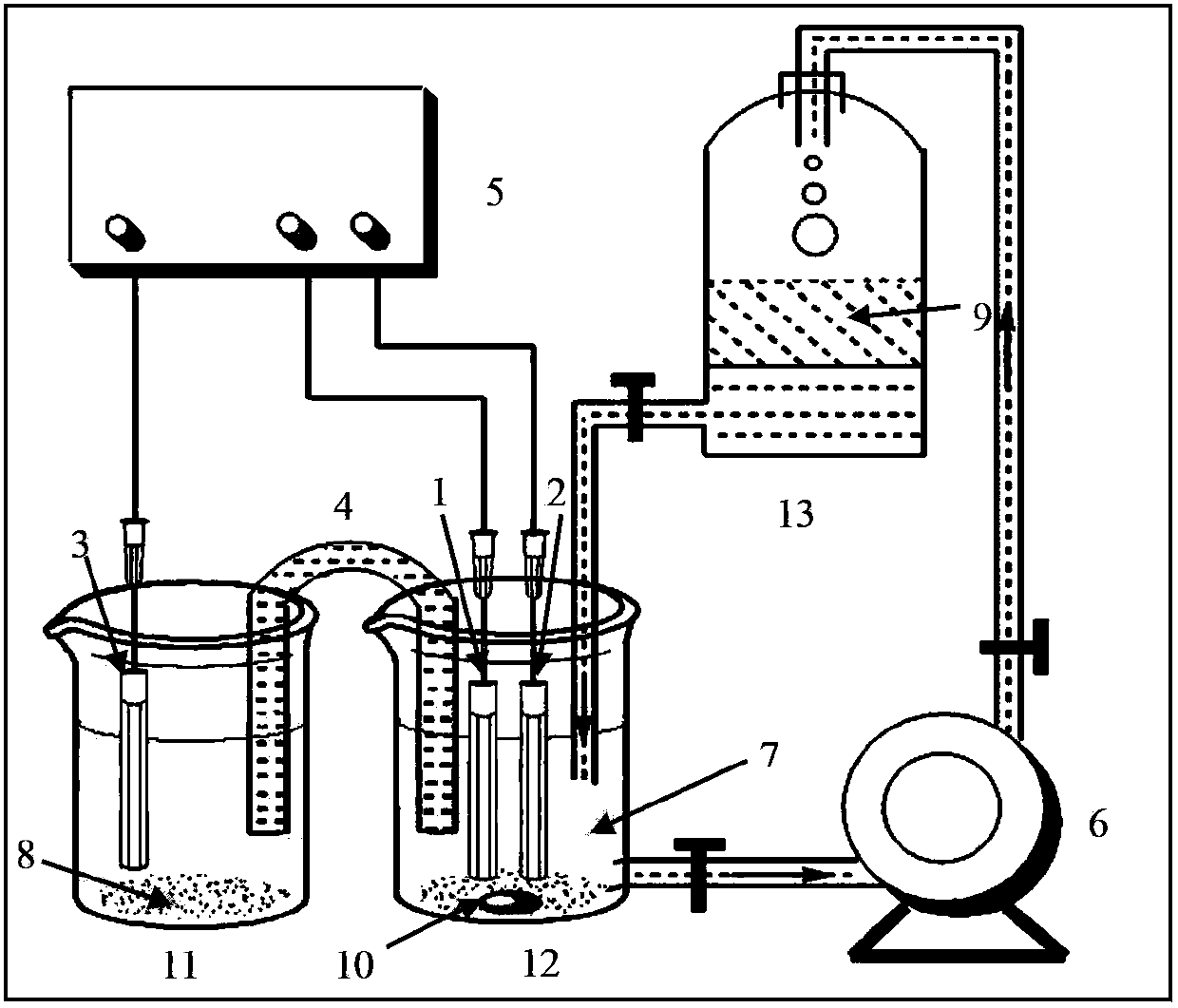

Method used

Image

Examples

Embodiment 1

[0030] (1) Disperse 4g lignin in 400ml FeSO 4 In the solution (0.05mmol / L), the lignin content is 10g / L, plus H 2 SO 4 (0.86mol / L) solution to adjust the pH of the solution to 3, and petroleum ether is used as the extract and placed in the extractor.

[0031] (2) Take 19.5 (3×6.5) cm 2Titanium mesh, Ti / La-Ce-α-β-PbO doped with La and Ce metals prepared according to related electrodeposition methods 2 The electrode (Separation and Purification Technology, 2013, (104): 9-16) is the working electrode. Take 14 (2×7) cm 2 The copper sheet was polished with 800-grit sandpaper, rinsed with distilled water and used as an auxiliary electrode.

[0032] (3) Add the prepared lignin suspension into the electrolyzer device, and electrocatalyze the degradation of lignin with a constant current, with a current density of 15mA / cm 2 , degradation reaction 4h, gas chromatography analysis showed that the concentration of DBP in the extract was 1.45g / L.

[0033] (4) After separating the or...

Embodiment 2-7

[0038] Examples 2-7 show that the dispersion concentration of lignin in ferrous sulfate solution (0.01mmol / L-0.15mmol / L) is 10g / L, and the current density is 15mA / cm 2 , under the condition that the reaction time is 4h, pH=3, the influence of different concentrations of ferrous sulfate solution on the yield of the product dibutyl phthalate (DBP) (see Table 1), other operating steps are the same as in Example 1.

[0039] The influence of table 1 ferrous sulfate solution concentration on the output of product dibutyl phthalate (DBP)

[0040]

Embodiment 8-14

[0042] Examples 8-14 are the dispersion concentration of lignin in ferrous sulfate solution (0.05mmol / L) is 10g / L, and the current density is 15mA / cm 2 , the effect of different pH values on the yield of the product dibutyl phthalate (DBP) under the condition of a reaction time of 4 h (see Table 2), and other operating steps are the same as in Example 1.

[0043] The influence of table 2 pH value on the output of dibutyl phthalate (DBP)

[0044] project pH value DBP concentration (g / L) Example 8 1 1.82 Example 9 2 1.84 Example 10 3 1.45 Example 11 4 1.79 Example 12 5 1.63 Example 13 6 1.62 Example 14 7 1.60

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com