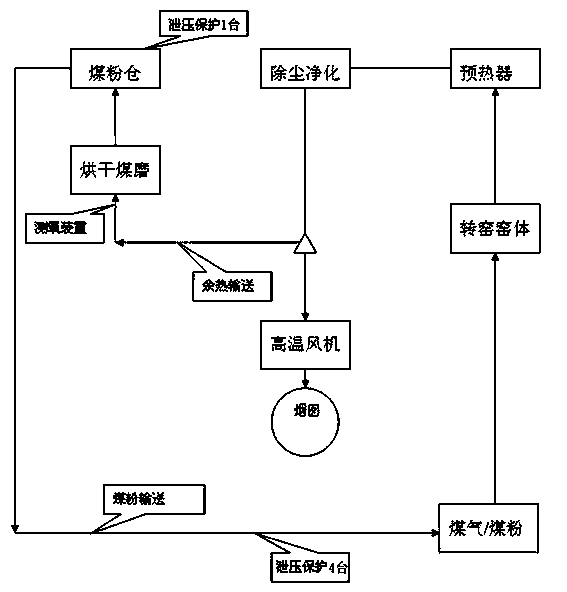

Waste heat utilization process for rotary kilns

A rotary kiln and waste heat technology, which is applied in the field of waste heat recovery or utilization, can solve the problems of waste heat resources waste, low utilization level and capacity, and scale limitation, so as to ensure low-oxygen operation, realize system safety protection, and realize functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention carefully selects the heat source point: one is to meet the heat energy and temperature required by the process, and the temperature required for drying pulverized coal is 120°C-150°C, and the excess temperature is not conducive to the stability of the system production operation; the other is suitable for easy The thermal energy safety environment of bituminous coal grinding and processing, and the low-oxygen waste gas are more conducive to operation control. Compared with kiln head and other waste heat resources, only dust removal tail gas can meet the above two conditions at the same time. The preferred conditions of the present invention are thermophilic anoxic state, t≥120°C, and oxygen content≤12% (volume percent concentration). Compared with the high-temperature oxygen-enriched state at the kiln head, the oxygen-deficient and suitable temperature of the exhaust gas waste heat is more conducive to system safety requirements.

[0019] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com